The full-automatic winding machine is a machine that winds linear objects onto specific workpieces. It is commonly used in inductive coils made of enameled wires in electrical parts, textile threads, yarn bursts and coils used in textile machines in the textile industry, as well as electric heating wires, solder wires, wires and cables used for winding electric heating appliances.

Winding machines are divided into general-purpose winding machines and special-purpose winding machines according to different purposes. Common winding machines include ring magnetic ring winding machine, full-automatic winding machine, cnc winding machine, winding stranding machine, cnc axis front double-axis automatic winding machine, four-axis winding machine, six-axis winding machine, voice coil numerical control winding machine, etc.

White Fox Design is entrusted by customers to innovate in terms of appearance design, structural design, product performance, functional configuration, man-machine operation, etc., and provide one-stop design and development services.

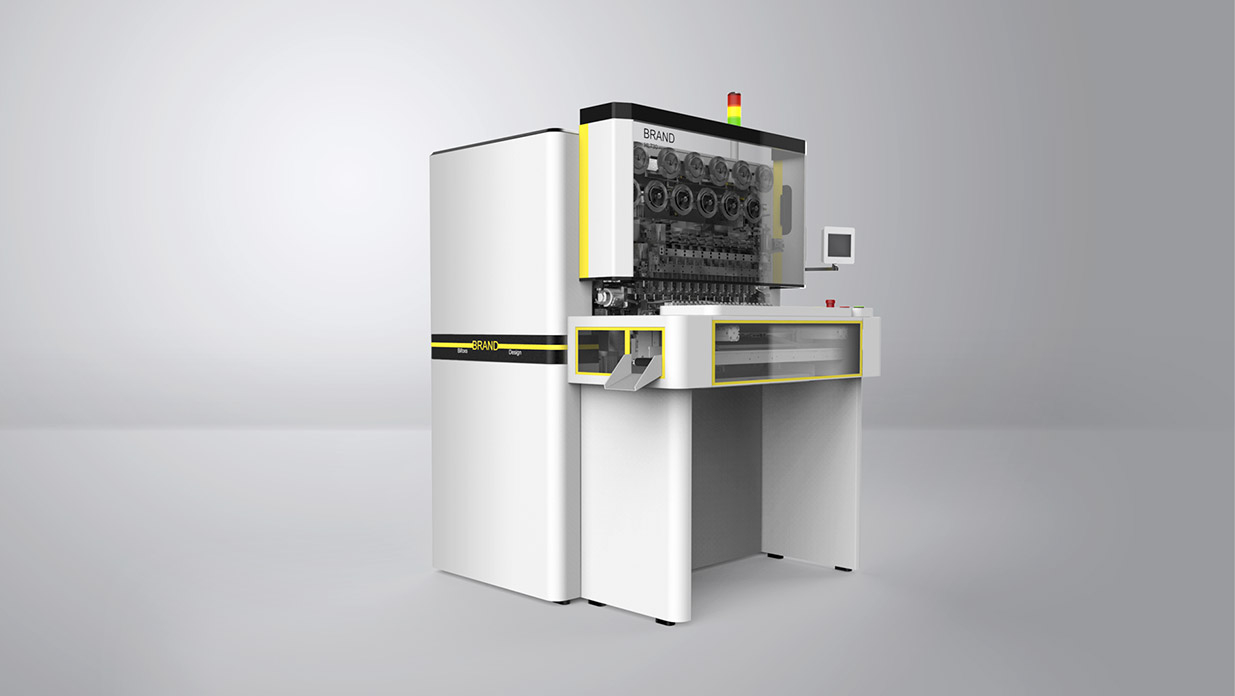

The appearance design of the automatic winding machine is simple and streamlined; it pays attention to detail treatment, the surface process is exquisite, the unique hot air dryer system, and the visual window can see the internal operation; it pays attention to the man-machine experience, and the operation is simple and convenient. The microcomputer control system is quick to respond, can save multiple sets of data at the same time, and is equipped with a password storage function to prevent non-related personnel from modifying the program.

The automatic winding machine has a compact body structure, modular design, linear, arc interpolation, spiral surround and other functions, stable performance, easy maintenance, high efficiency, good quality, strong stability, strong shock resistance, and winding The characteristics of high precision and good machine rigidity; select environmentally friendly materials, use standardized, universal, and serialized parts to minimize assembly errors caused by assembly, and avoid additional costs caused by non-standard parts, the application of reasonable manufacturing process, easy processing, assembly, shorten the manufacturing cycle, reduce manufacturing costs, reduce material and energy consumption, good performance, strong and durable.

The full-automatic winding machine is simple and convenient to use. The workpiece or copper wire is replaced in time during use. Under the condition of sufficient raw materials, automatic feeding, automatic winding, automatic winding, precision wiring, and automatic winding can be realized. Basic procedures such as tail, automatic wire cutting, automatic blanking, etc., can also realize various difficult steps such as right-angle outgoing line, wire pressing into the groove, etc., to improve the productivity of the winding machine.

The copyright of this work belongs to 白狐设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

It feels that structural engineers have a hard time.

What is the specific function of this machine?

Winding???

The picture feels a little mushy.