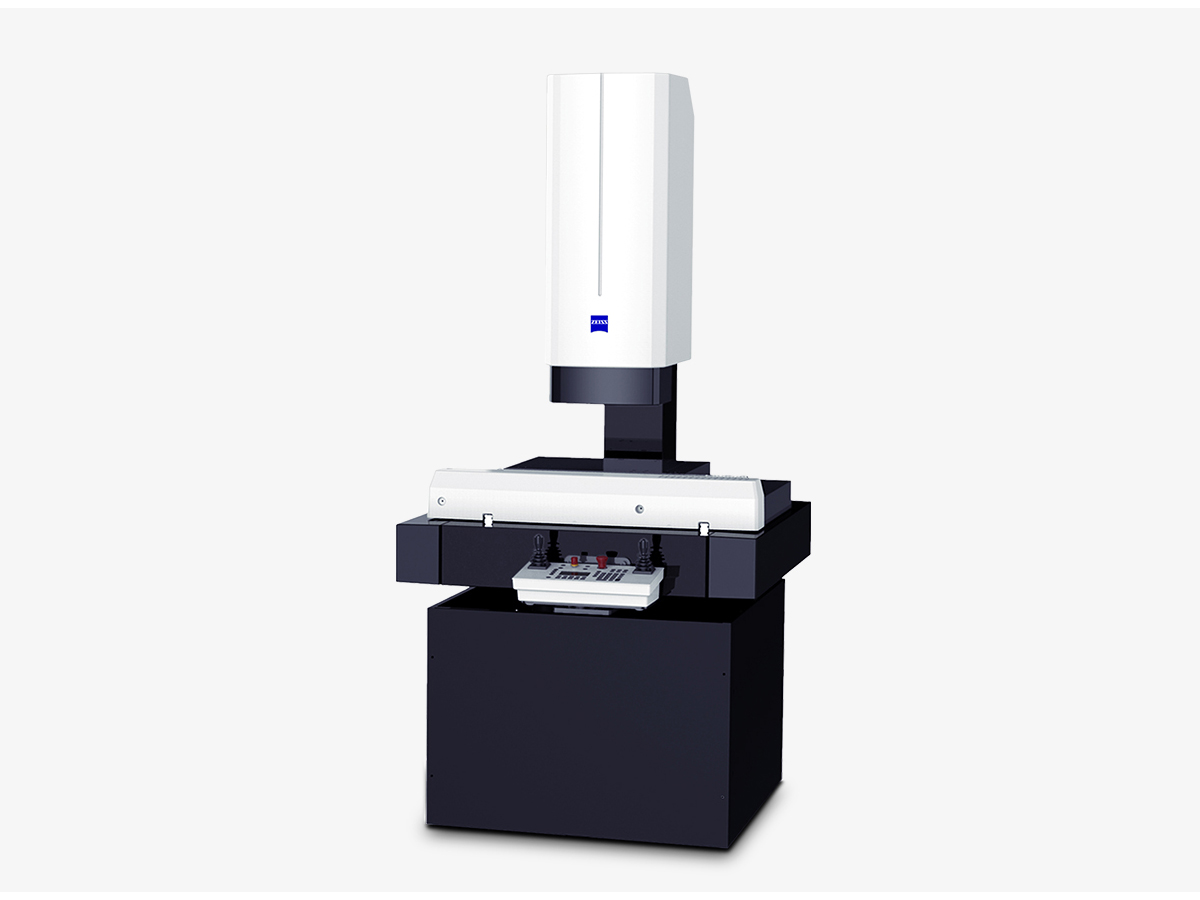

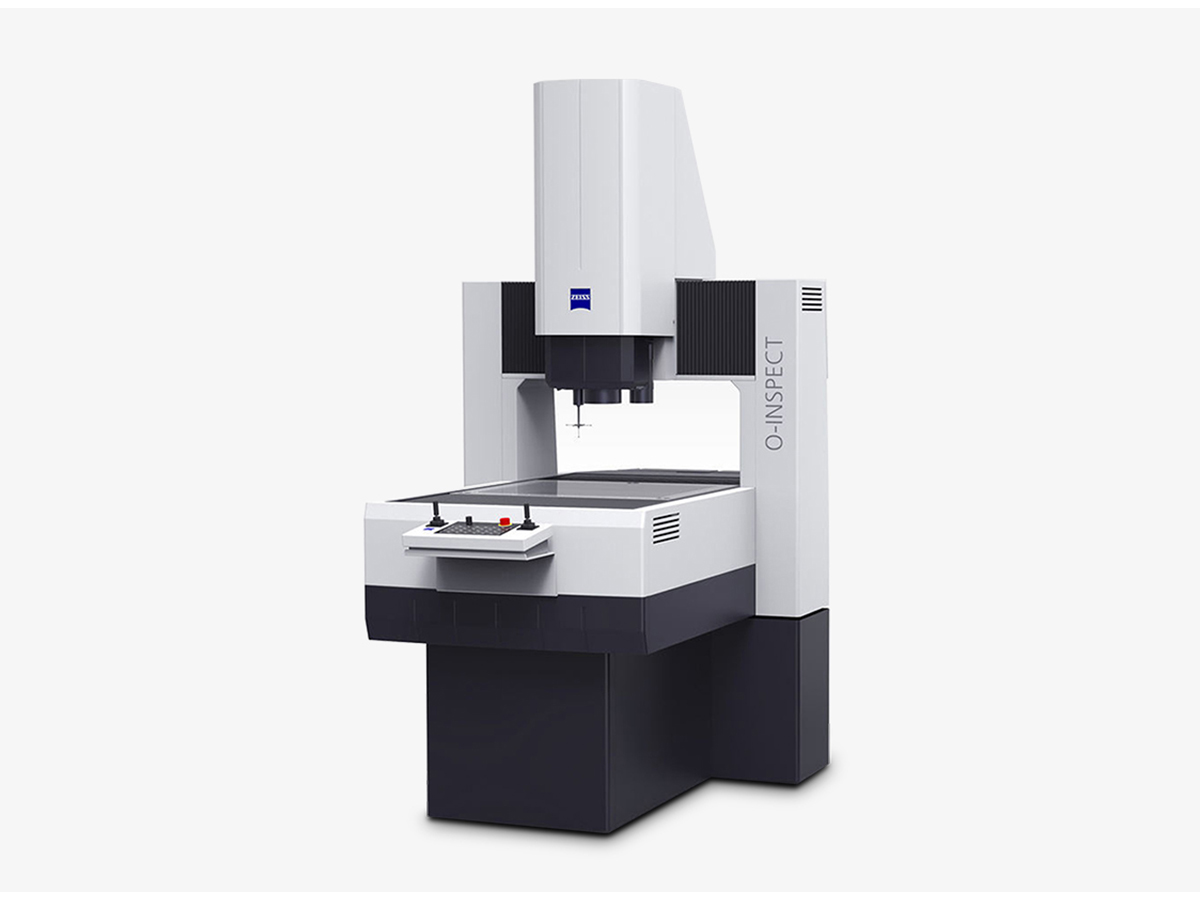

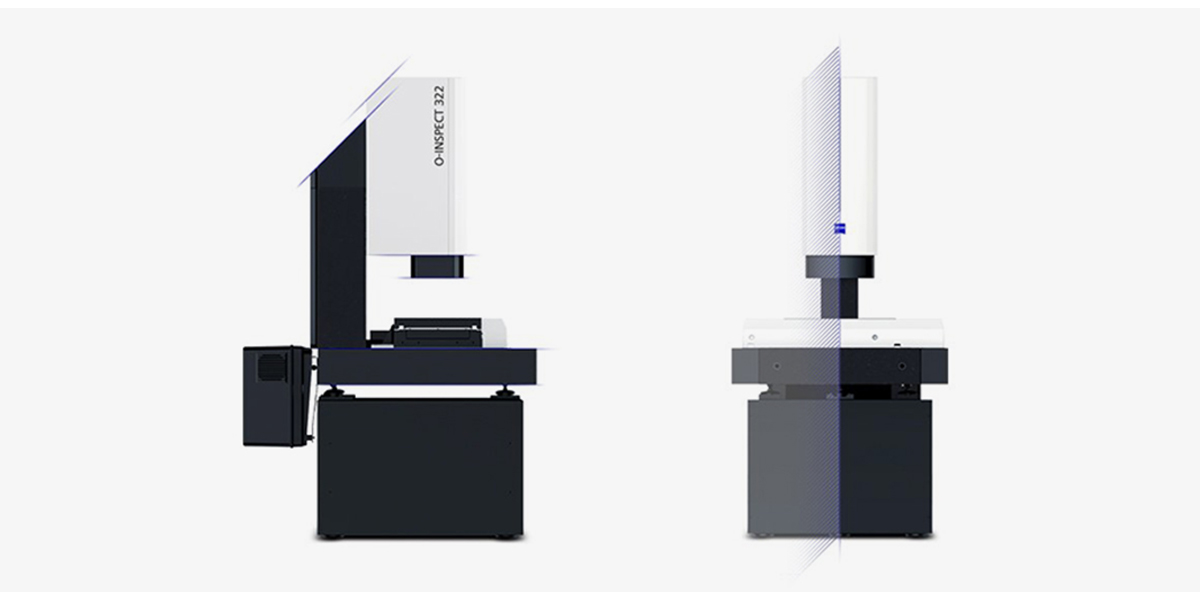

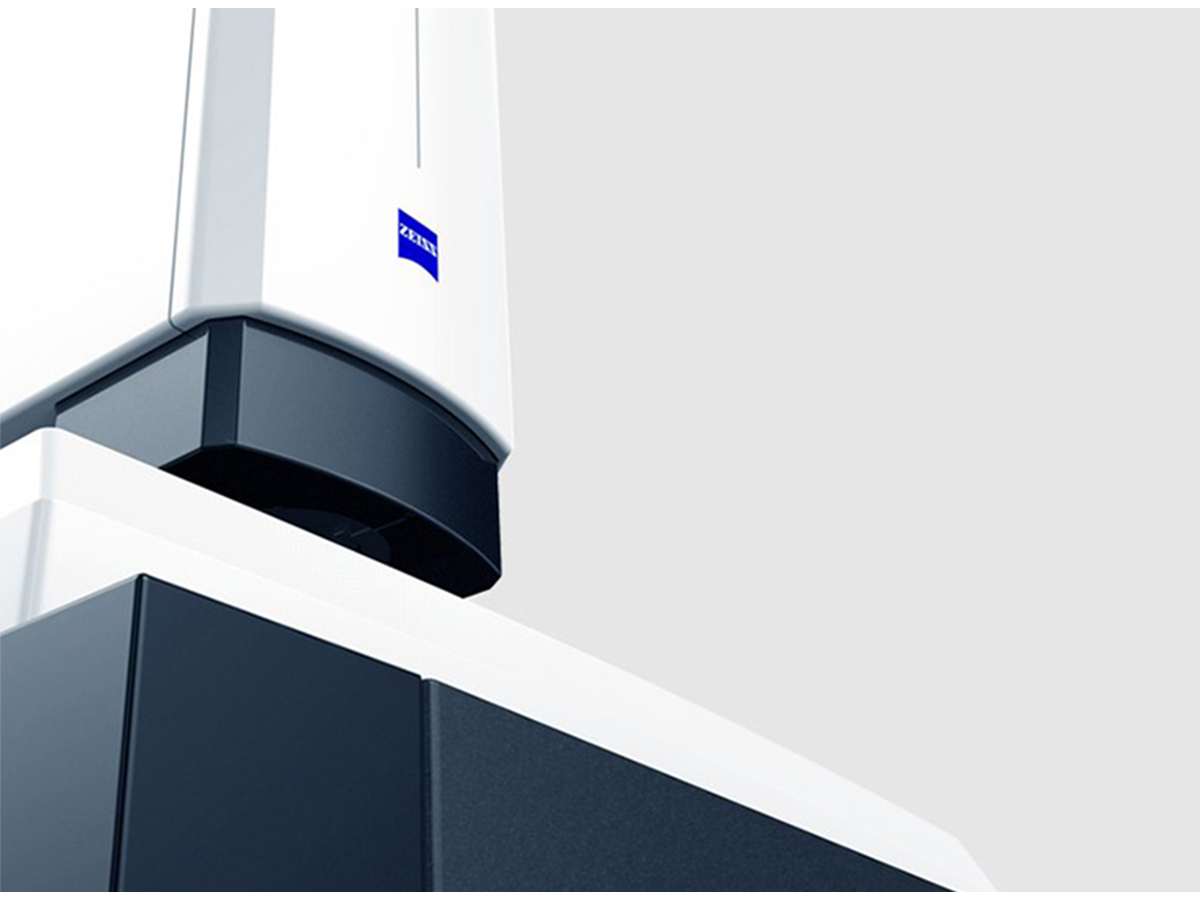

As a member of Zeiss's product family, Zeiss 3D measuring equipment has made a new breakthrough in design semantics in addition to the consistent rigorous and robust characteristics of the original products. The shell adopts the rear section design, which greatly reduces the volume. The main chassis innovatively adopts the rear backpack design to make the equipment more integrated. At the same time, it is more dexterous in shape.

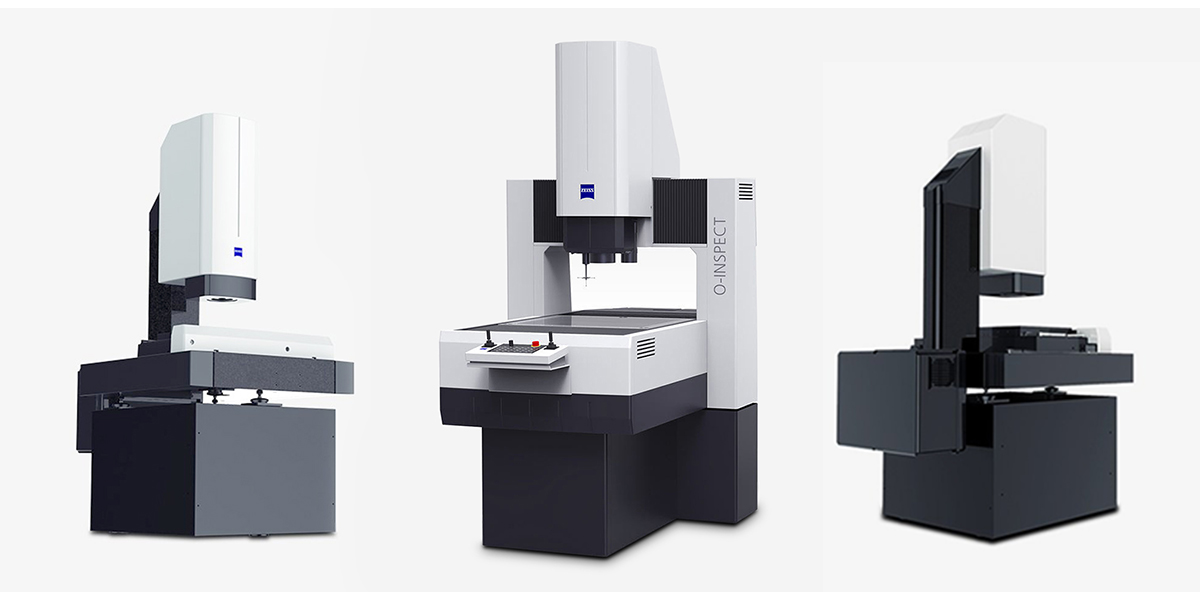

Carl Zeiss (Shanghai) Management Co., Ltd. found the Trojan horse design this time, hoping to continue its family products on the basis of its own brand image through the power of industrial design, and at the same time integrate beauty and quality. After careful and in-depth understanding of the brand image, combined with the industrial characteristics of the three-dimensional measuring equipment, we solve technical problems with design thinking, and after many times of brainstorming and creative hand-drawing, we set off our creativity. In the process of selecting and deepening the scheme for many times, we always keep close contact with Zeiss, listen carefully to the opinions of customers, and be responsible for each decision. Finally, the plan was established and a new generation of OES322 three-dimensional measuring equipment was produced. This model uses the rigorous symmetry design, as well as the simple straight line and large section design, so that the precision of industrial equipment incisively and vividly. The rear section design makes the product rhythmic, with a smart head and a stable base, without appearing top-heavy. The main chassis innovatively adopts the rear backpack type to make the equipment more regular. There is a wiring slot design at the rear, which covers the messy wires, making the shape more concise and professional, and avoiding safety accidents. Zeiss EOS322 3D measuring equipment uses marble desktop, which greatly increases the accuracy of measurement. At the same time, the base is optimized. There are two optional bases, one of which has a shelf for convenience and practicality, and the other is a low-cost type, which reduces the cost by nearly 70%. The forklift plug is located in the middle of the product, not the bottom, and it is safer during transportation operations.

Zeiss China is a subsidiary of Carl Zeiss in China. Its main business scope covers industrial measurement, medical treatment, scientific research and other fields. Its technology and quality have always been in the leading position in the industry. The product console can be placed on the front or side of the equipment as required, which is convenient to operate; the marble desktop is used, which greatly increases the accuracy of measurement, and finally realizes the full link consideration from design to transportation.

The copyright of this work belongs to 木马设计总部. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Thank you for sharing

Learn