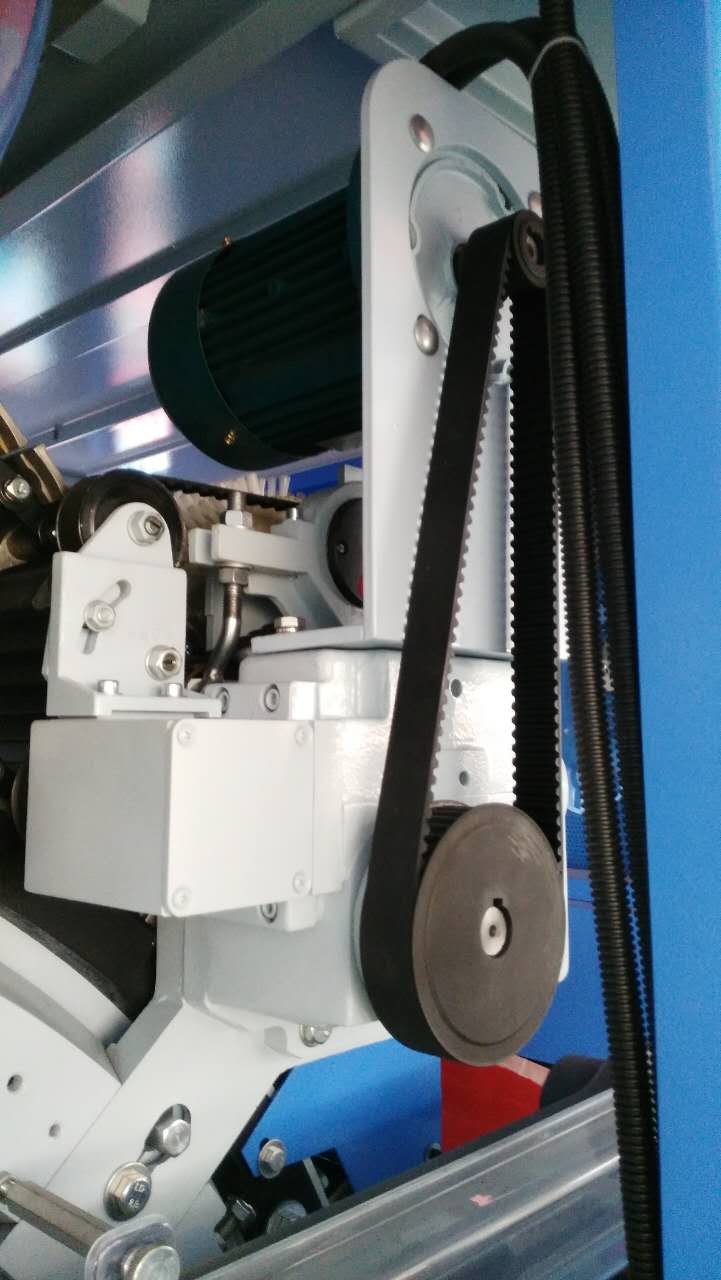

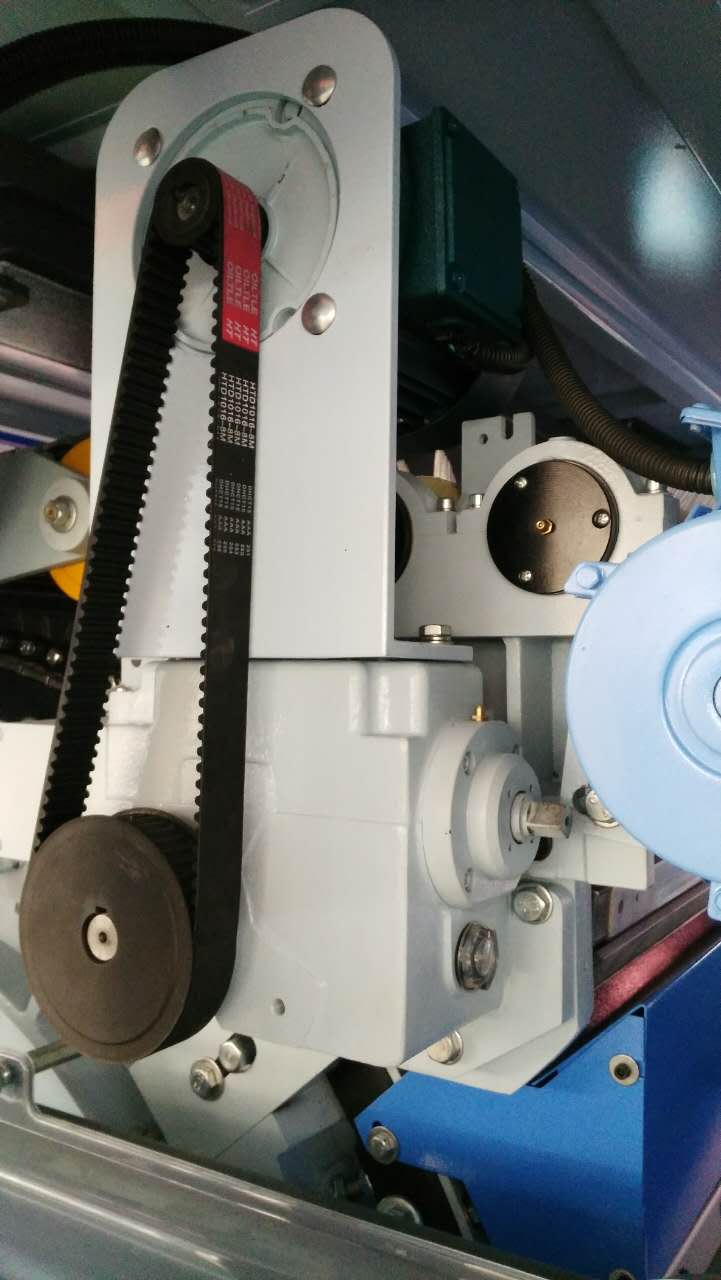

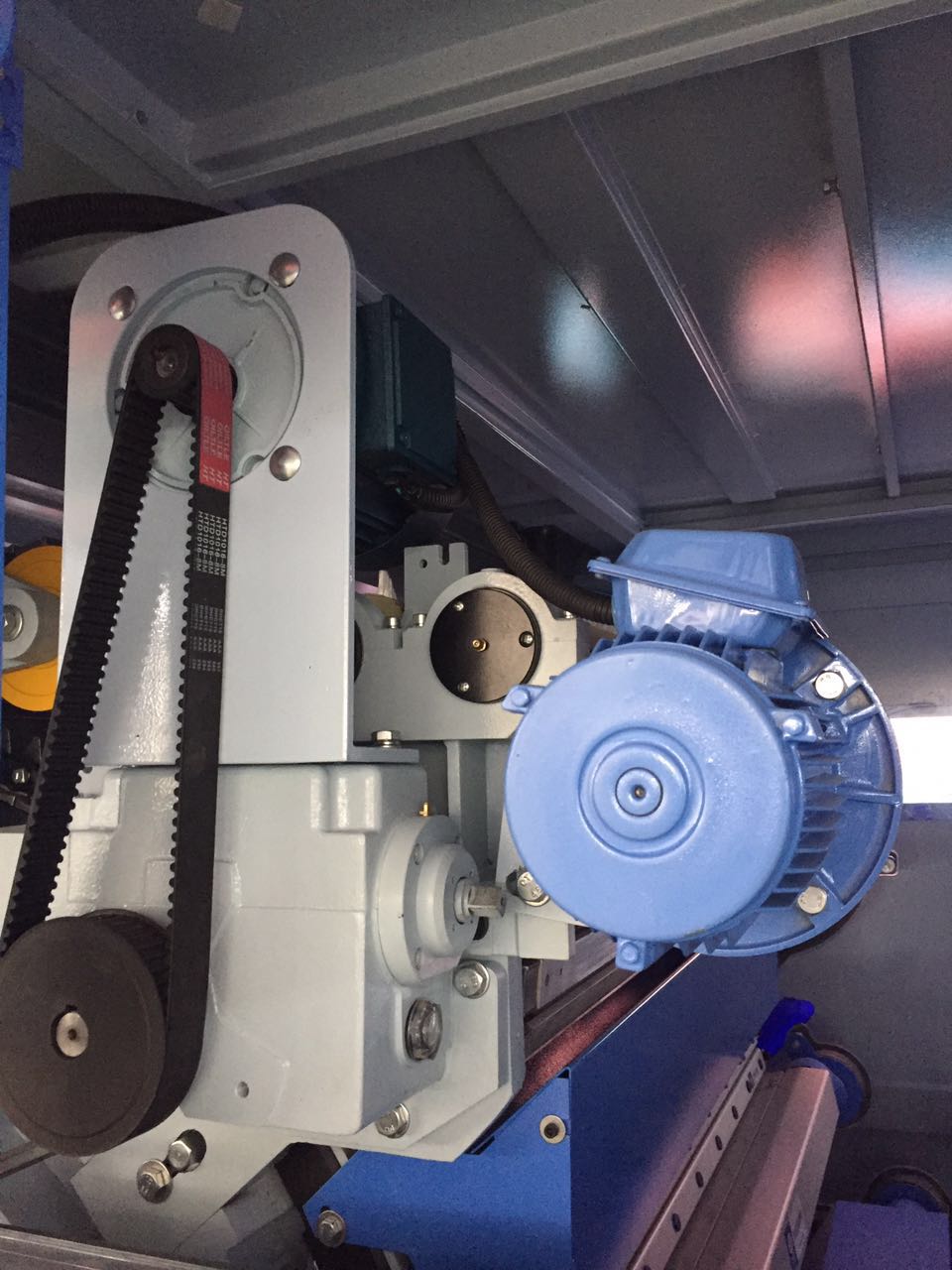

The separate motor transmission system of the cover plate adopts the motor to drive the movable cover plate, and the frequency converter is used to control the motor speed to be adjustable, and the on-line process adjustment is implemented. The speed of the cover plate can be adjusted at any time according to the different varieties and raw materials of the spun, which has been applied to the spinning process requirements. The system is mainly composed of gear gearbox, frequency converter, energy-saving motor, motor seat, synchronous belt wheel and synchronous belt. It changed the original mechanical transmission mode, from the original cylinder drive to a separate motor transmission, thus realizing frequency conversion speed regulation.

It brings convenience and efficiency to workshop equipment management and operators. Before, it is necessary to manually replace the process wheel to adjust the speed of the cover plate, which is laborious and time-consuming, and is prone to errors, resulting in product waste. Now only by adjusting the electronic control system, the frequency of the frequency converter can change the speed of the cover plate, which is simple and convenient, and the efficiency is greatly improved. But also saves, a lot of process exchange wheels, saving materials. The safety performance has also been improved, because before the use of cylinder transmission cover, with long flat belt transmission, there are potential safety hazards, a slight operation error, it is easy to cause accidents. In design, it is more beautiful and beautiful than before.

For details, please go to: http://successfuldesign.org/work/596f0abaf33fd5254932b2f4

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Comment Board (0)

Empty comment