CNC label die-cutting machine for warp and weft

Owners

Owners

Owners

With the continuous development of big data, Internet of Things and artificial intelligence in China, the trend of automation in the die-cutting industry is becoming more and more obvious. Modern die-cutting machines can realize man-machine dialogue to improve the operation convenience of technicians.

After investigation, we learned that the current die-cutting machine can be divided into flat die-cutting machine, round flat die-cutting machine, laser die-cutting machine and round knife die-cutting machine (also known as round die-cutting machine). Among them, flat, round flat, laser die-cutting is mainly non-continuous die-cutting, round knife die-cutting machine for continuous die-cutting process. The flat die-cutting technology is relatively mature and is generally used for simple punching of materials with high thickness and hardness, with low efficiency in large-scale production. The press-cutting mechanism of the round flat die-cutting machine is a roller, which is used for discontinuous die-cutting by rolling the roller on the plate, but the roller and the plate are easy to shift, and this kind of equipment is rarely used in our country; laser die cutting technology is directly controlled by the computer laser cutting, generally used for small batch cutting of micro devices, and the production cost is high.

With the increase of the types of die-cutting materials, the improvement of die-cutting efficiency and process level, the application field and industry demand of round knife die-cutting are also growing, and round knife die-cutting has become the mainstream process of die-cutting industry.

The die-cutting industry itself covers die-cutting machine manufacturers, mold manufacturers, die-cutting processing/foundry companies, etc. The die-cutting step mainly depends on the die-cutting machine supporting the corresponding mold, die-cutting machine is an important equipment in the industry.

With the continuous development of the die-cutting industry, relevant enterprises in the industry continue to accumulate experience and deepen technology, and more complex die-cutting operations can be realized at present.

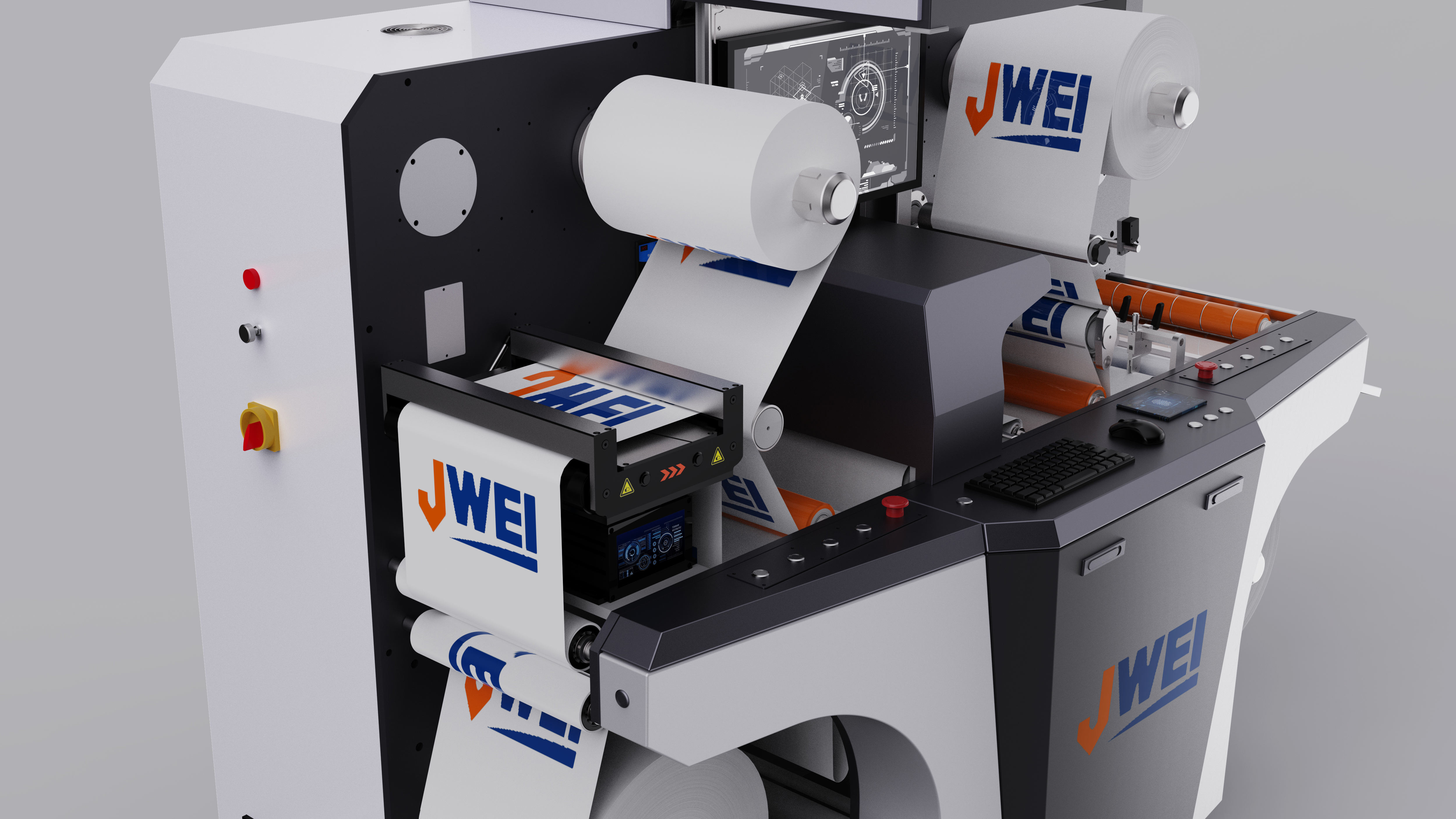

The die-cutting machine with increased functional components can realize different effects such as hot pressing, printing, folding, embossing, adsorption collection, etc. at the same time of die-cutting, and can be widely used in medical and health, new energy and automobile fields to greatly improve production efficiency. The multi-function of die-cutting machine brings new opportunities for die-cutting equipment.

Die cutting machine to automation, high efficiency, multi-functional direction.

Summarizing the above design insight, the problems found and the development trend, we focus on the warp and weft industrial appearance style, and achieve high speed, high precision, high hardness. As a leader in the cutting field of the advertising industry, we need to break the situation and redefine cutting!

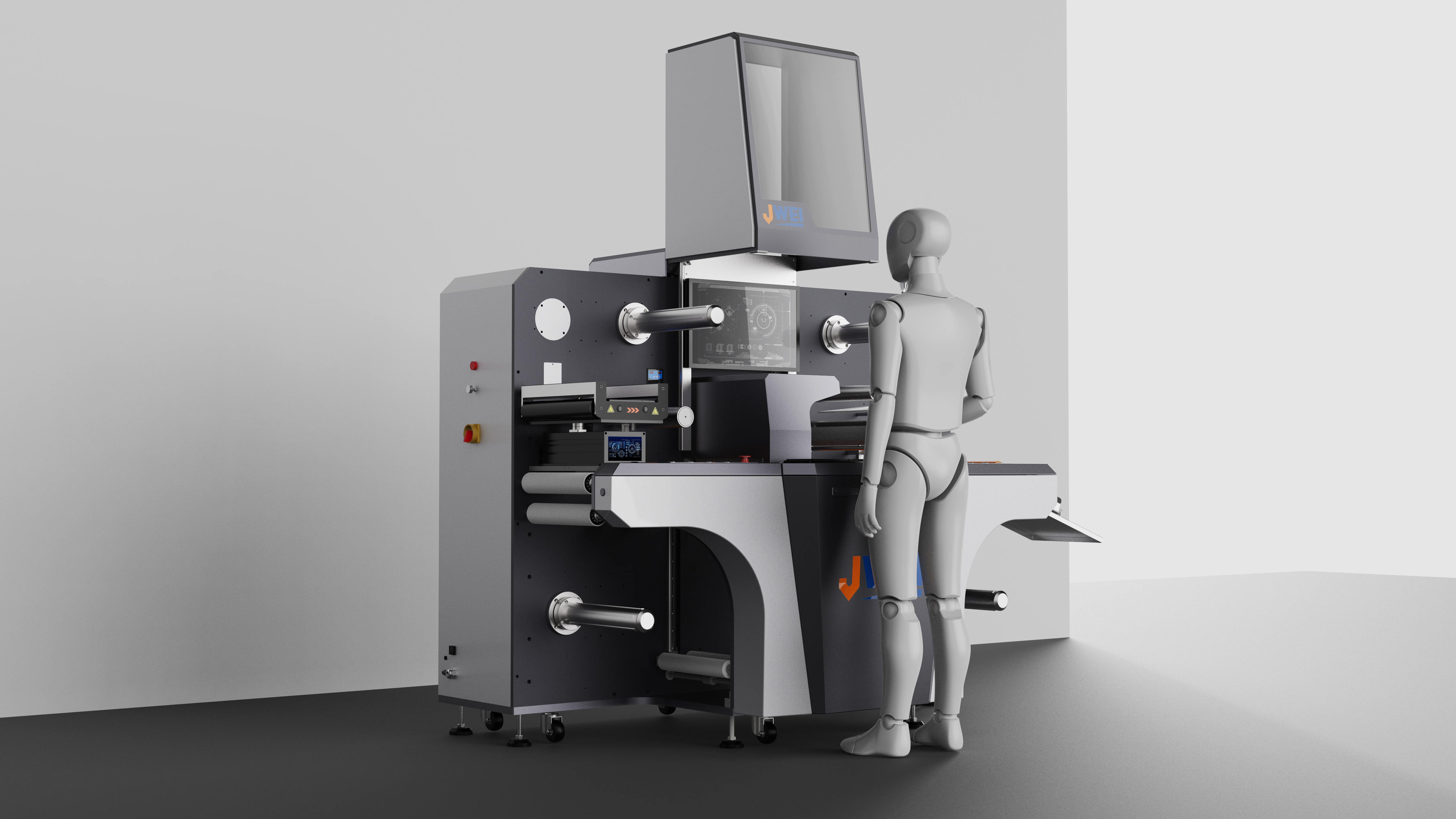

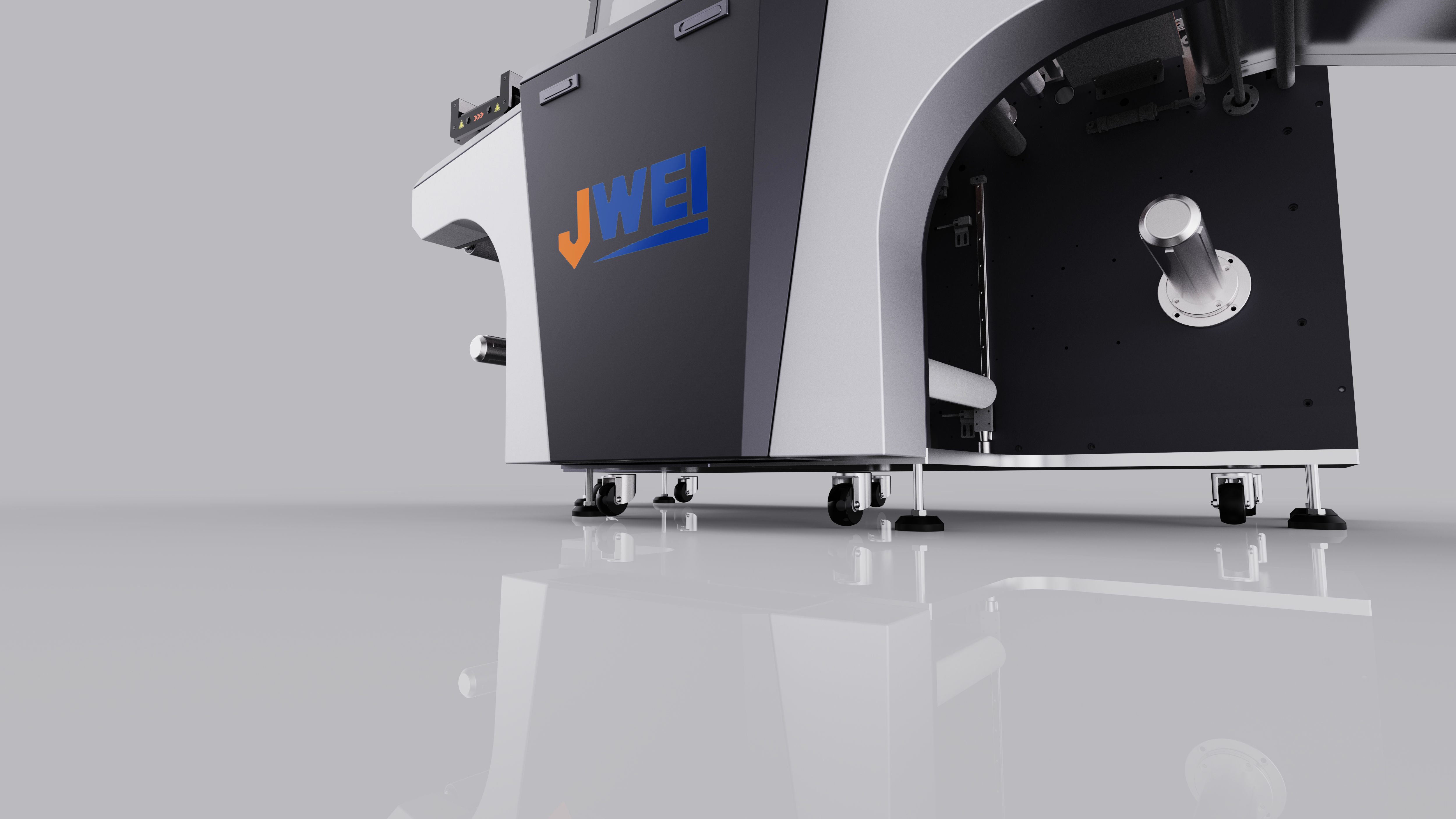

The appearance contour curve of this label die-cutting machine we designed is hale and hearty, and the back plate is designed with wrapping feeling. Combined with the simple and low-key lines at the front end, it highlights the high end and combines with each other at the same time, reflecting the unified, stable and elegant gentleman feeling. The use of angular and stable and calm design, so that the product in the stable and increased the development and enterprising. The back panel and front cover use a calm black, which echoes the front and back and increases the stability of the product. Use and brand consistent color matching, structure, to create a series of products.

The copyright of this work belongs to Dany. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

This rendering effect is simply too strong

It's really nice

Listen to this name is very professional

learning to learn

High precision