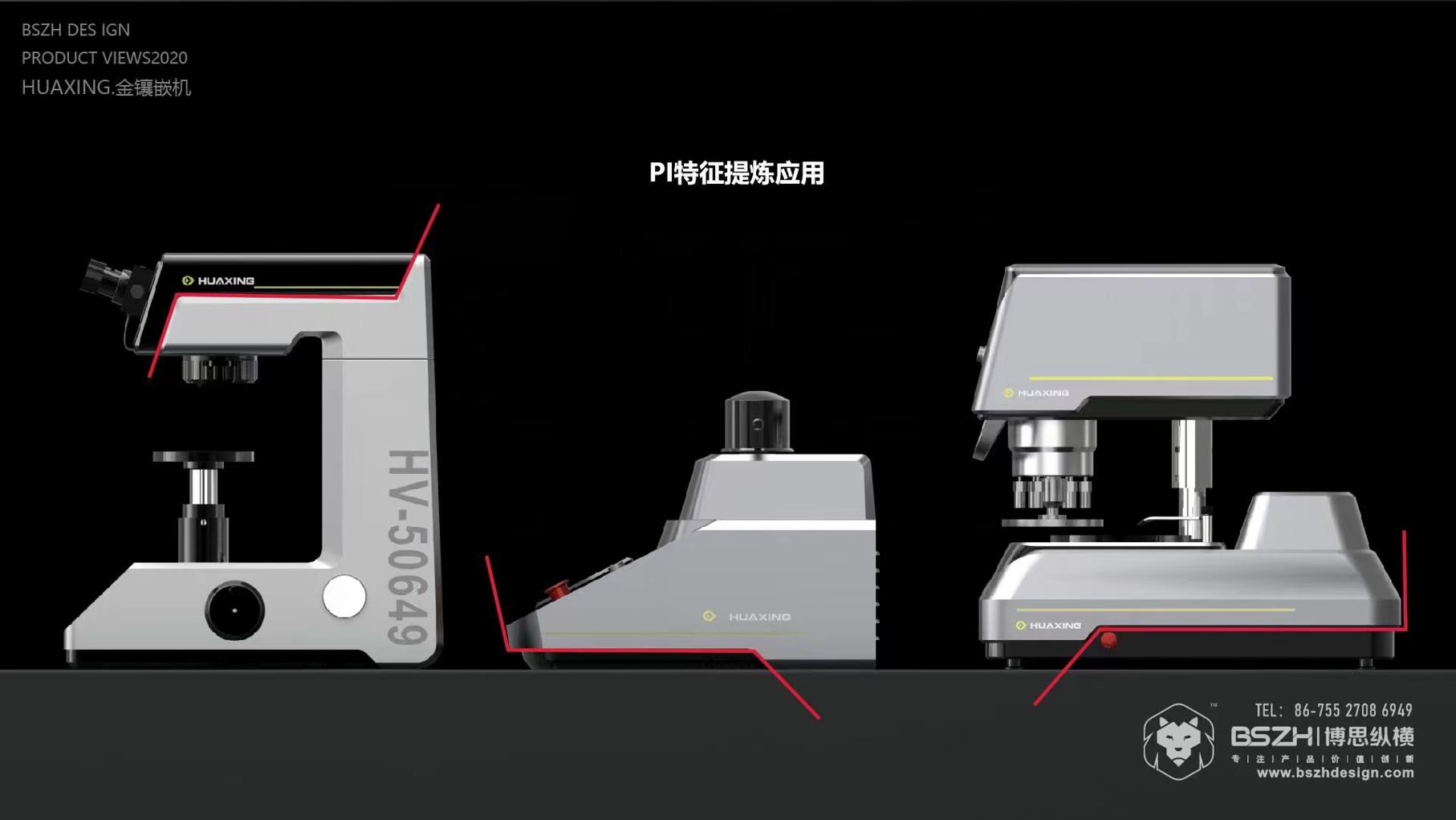

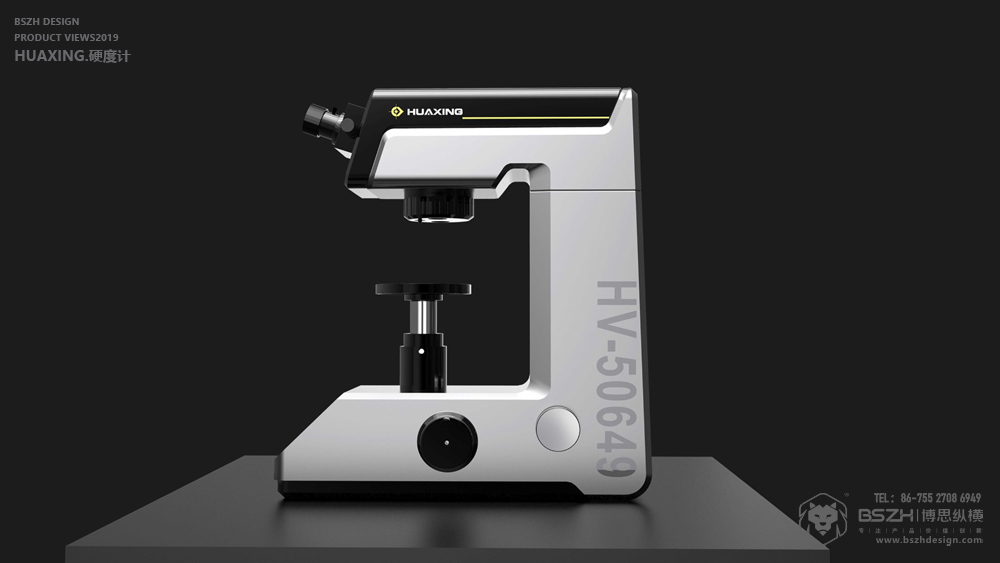

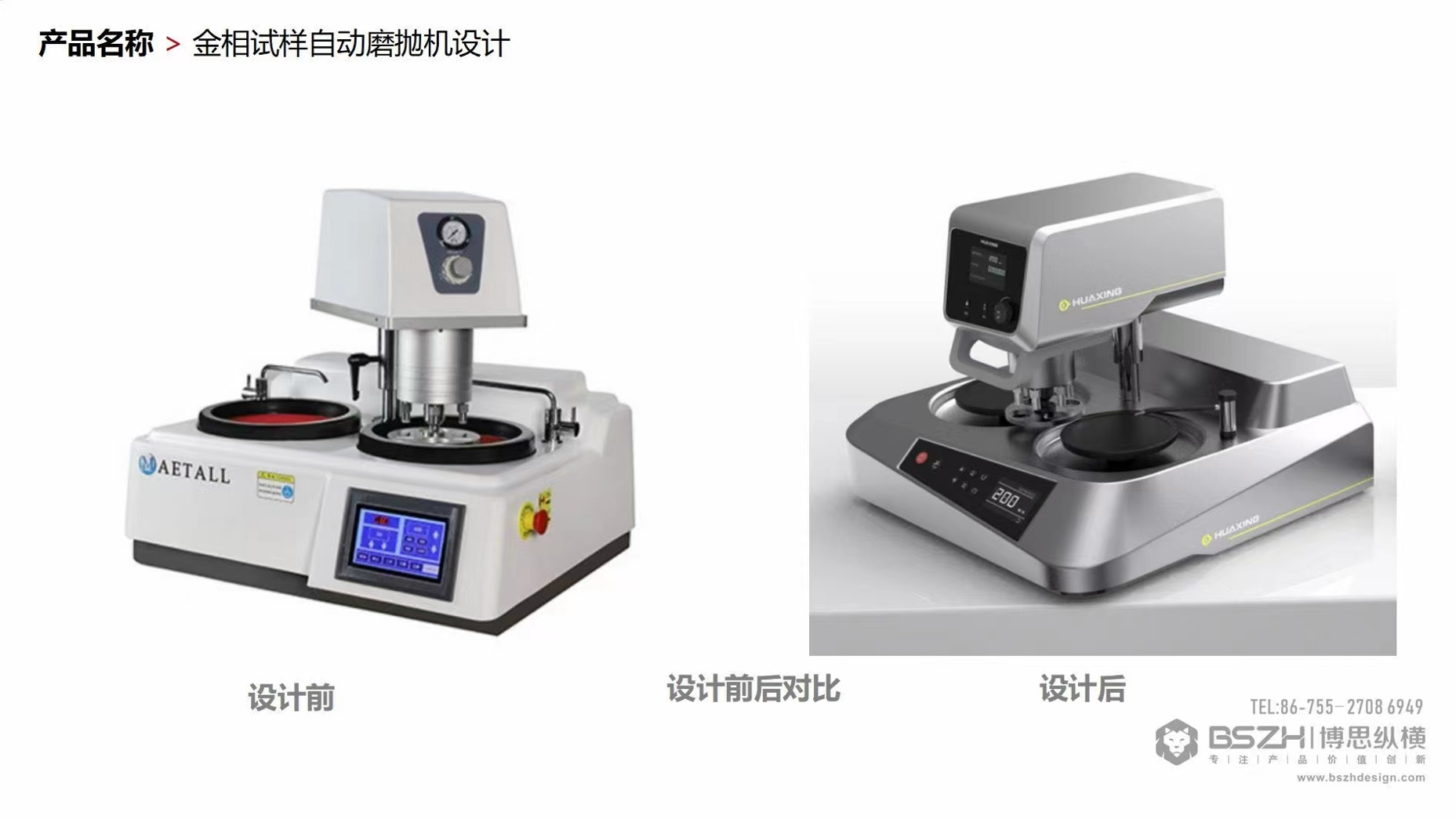

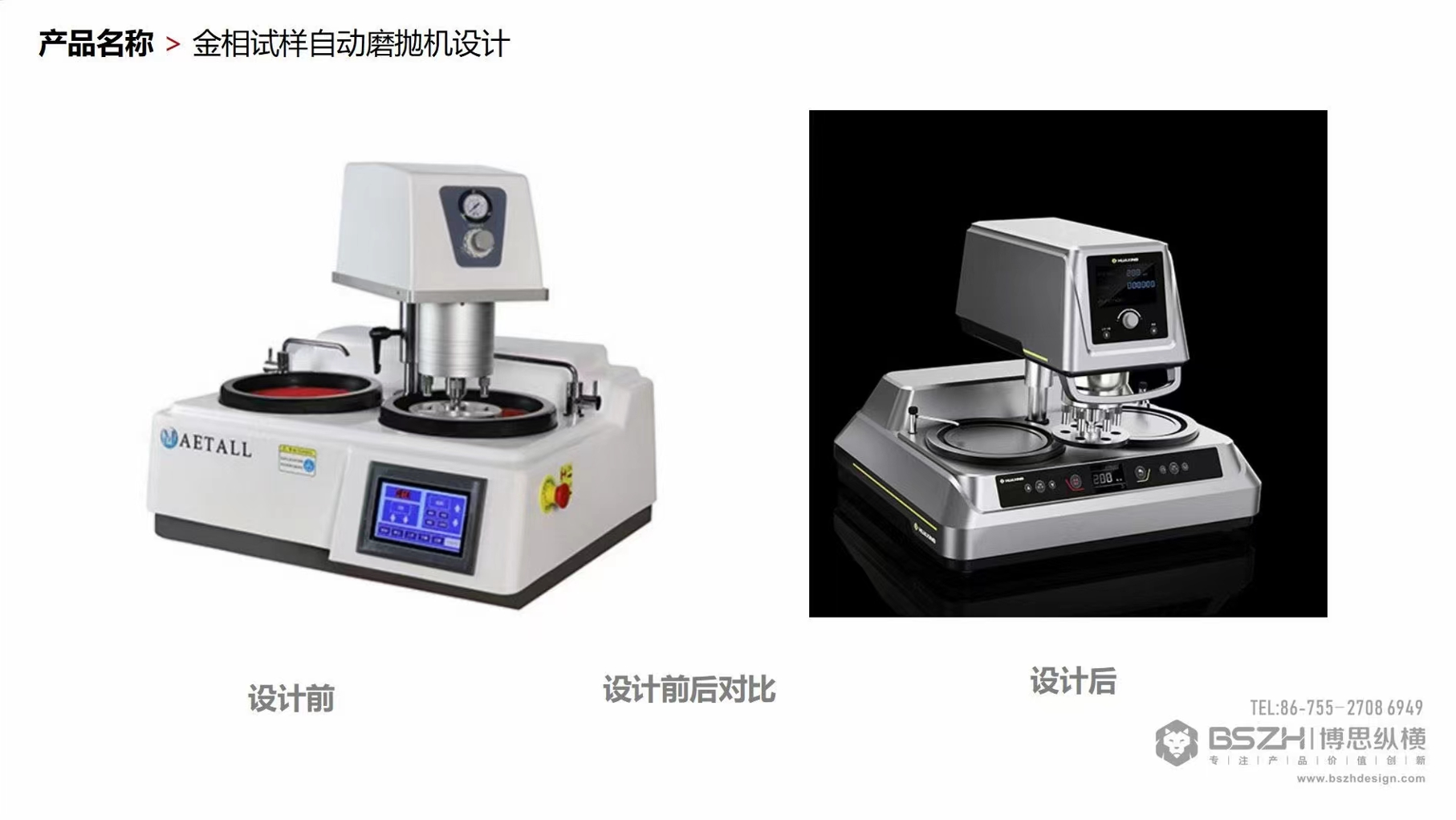

Huaxing HUAXING | high-end instrument PI series family design

Make energy more efficient, make the world better!

Service content: industrial design, product design, appearance design, structural design

Focus on precision instrument design to provide enterprises with a complete strategic system innovation for tea farmers, upgrade the image and update the design of the whole series of products, and the appearance design and function innovation of the newly designed Vickers hardness tester are based on a digital Vickers hardness tester. This digital Vickers hardness tester should solve the technical problems in the existing technology that the loading method of Vickers hardness tester has large error, the loading time cannot be randomly adjusted according to the sample, the test accuracy is low, and the operation is inconvenient. This digital display Vickers hardness tester is composed of a frame, a lifting sample table fixed on the frame, an indenter above the lifting sample table, an objective lens and a lever, and a power mechanism connected to the rear end of the lever. The indenter, the objective lens, the lever and the power mechanism are all arranged on the frame, wherein the power mechanism is composed of a motor and a ball screw, and the upper end of the ball screw is connected with the rear end of the lever, the output shaft of the motor is connected with a nut matching the ball screw through a transmission device, the indenter is fixed on the indenter handle, the indenter handle and the objective lens are both fixed on a rotating arm, the middle of the rotating arm is connected with a rotating arm motor, the rotating arm motor is fixed on the frame, the upper end of the indenter handle is connected with the lever, and a pressure sensor is arranged between the indenter and the indenter handle, the signal output terminal of the pressure sensor is connected to an analog-to-digital converter through an amplifier, the analog-to-digital converter is connected to a controller, a digital automatic encoder is provided on the side of the indenter, and the signal output terminal of the digital automatic encoder is connected to the The controller is connected, and the controller is connected to the control end of the motor and the boom motor.

The copyright of this work belongs to 博思纵横咨询设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

What material is the new design shell

Add chicken legs to the boss

this is really too fine

The exterior design is very good, but it is divorced from reality. The sales volume of the instrument is very small, and the mold opening cost is too high. If it is made of sheet metal, the processing is too difficult and the cost is also very high. For example, the hardness tester has a market price of about 10000. The cost of sheet metal alone will not be lower than 4000. With other components, it will be at least 2000. With VAT of about 1000, the total cost will reach 7000, plus the cost of sales, at least 20% of the selling price, to increase the 2000, that also earn a wool. If the price of the instrument is not more than double the cost, it will be a loss.

It's really good

Thanks for sharing