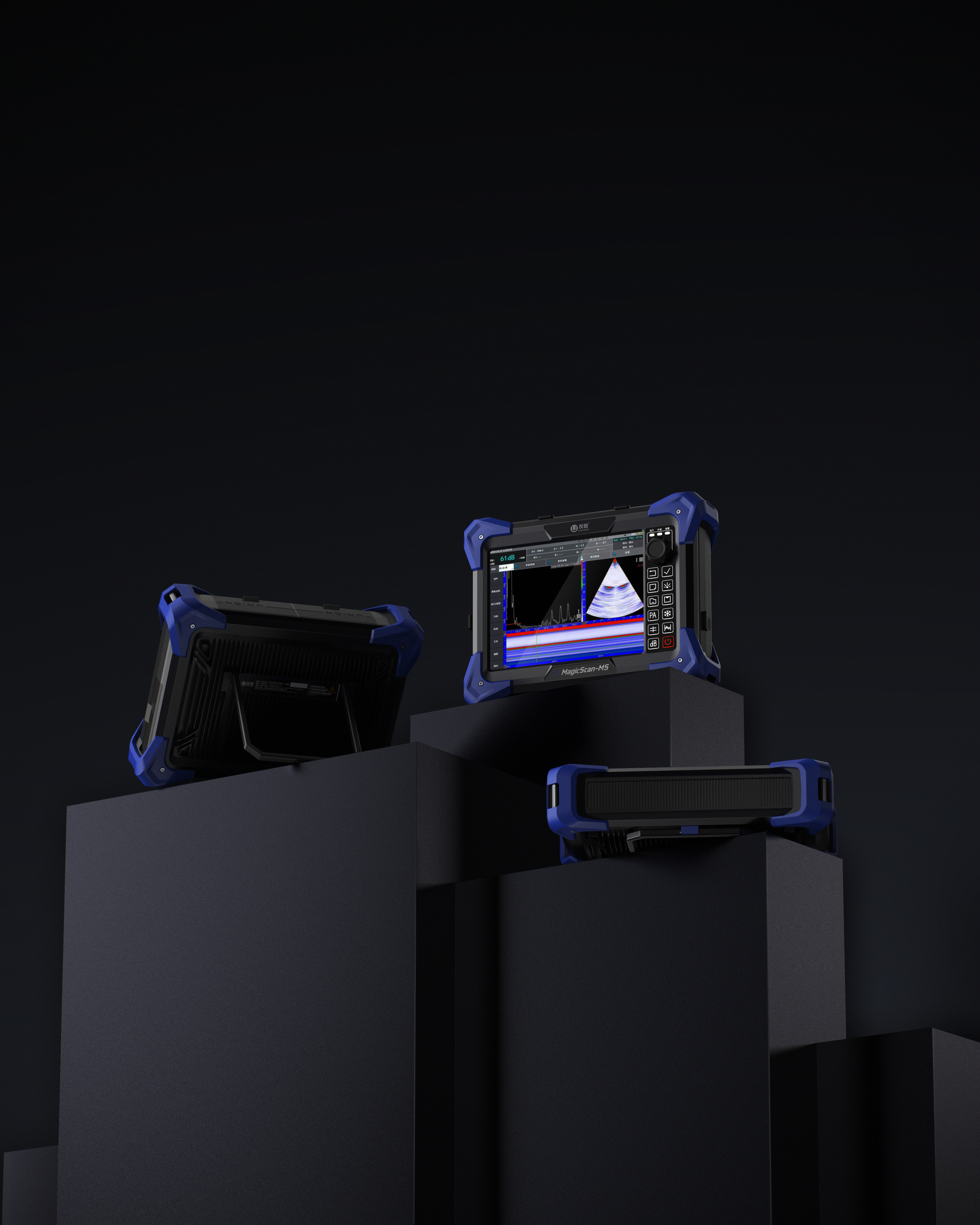

Flaw detector is mainly used to detect whether there are defects (cracks, sand holes, pores, white spots, inclusions, etc.) in the machining parts of the machine, whether the welding seam is qualified, and whether there are dark injuries, so as to determine whether the workpiece is qualified or not.

The flaw detector is mainly used to detect whether there are defects (cracks, sand holes, air holes, white spots, inclusions, etc.) in the machined parts, whether the welds are qualified, and whether there is any hidden damage, so as to determine whether the workpiece is qualified.

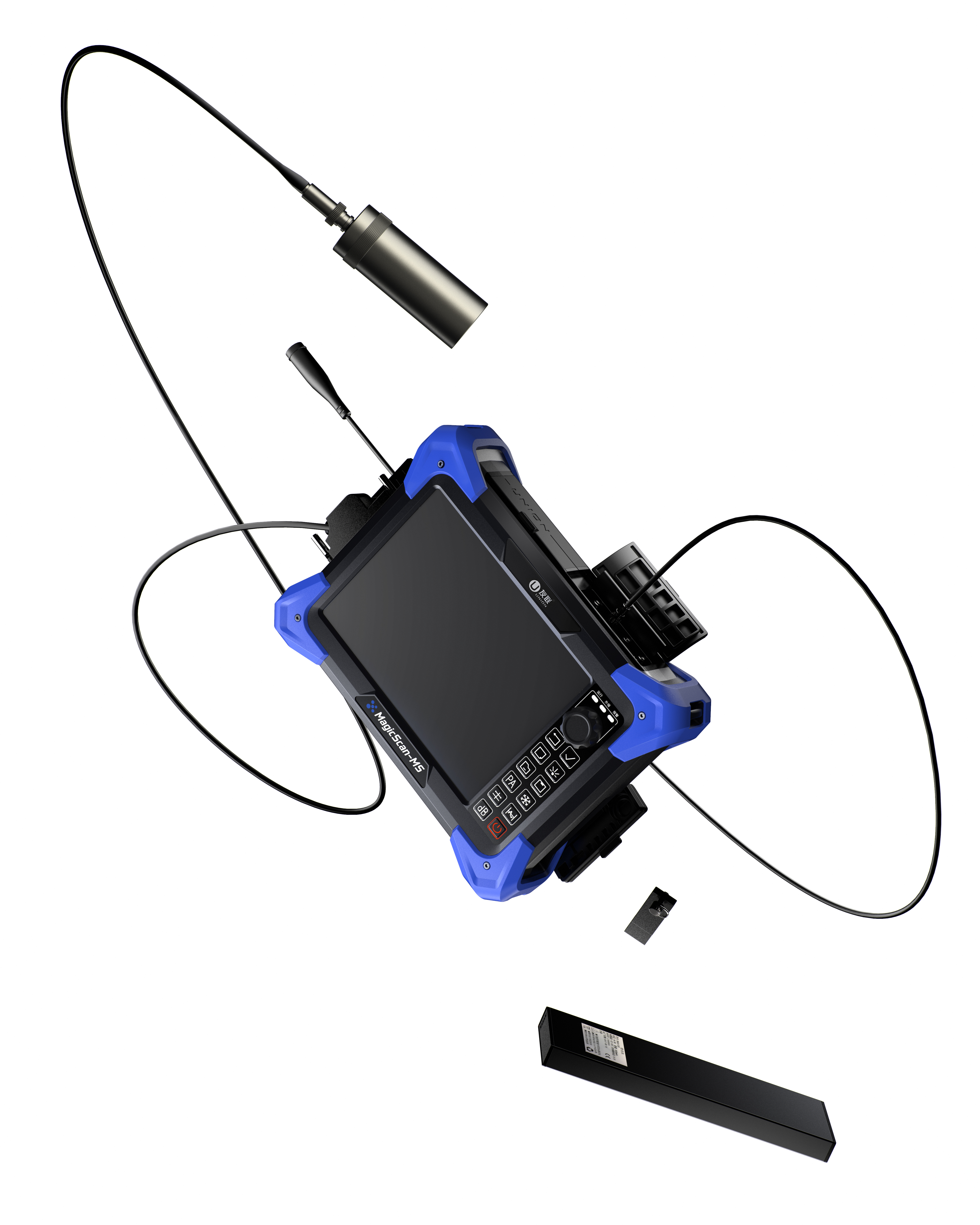

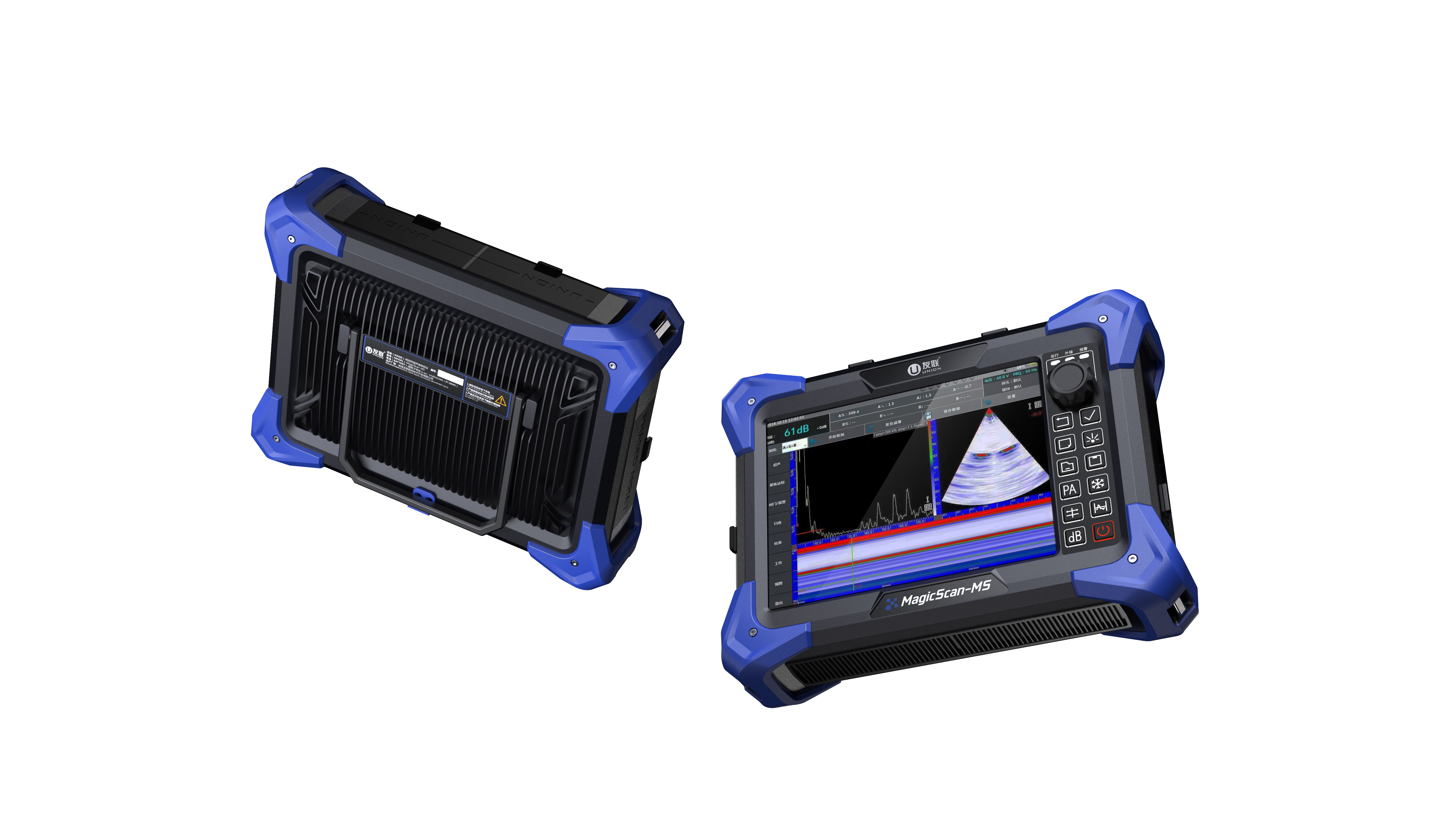

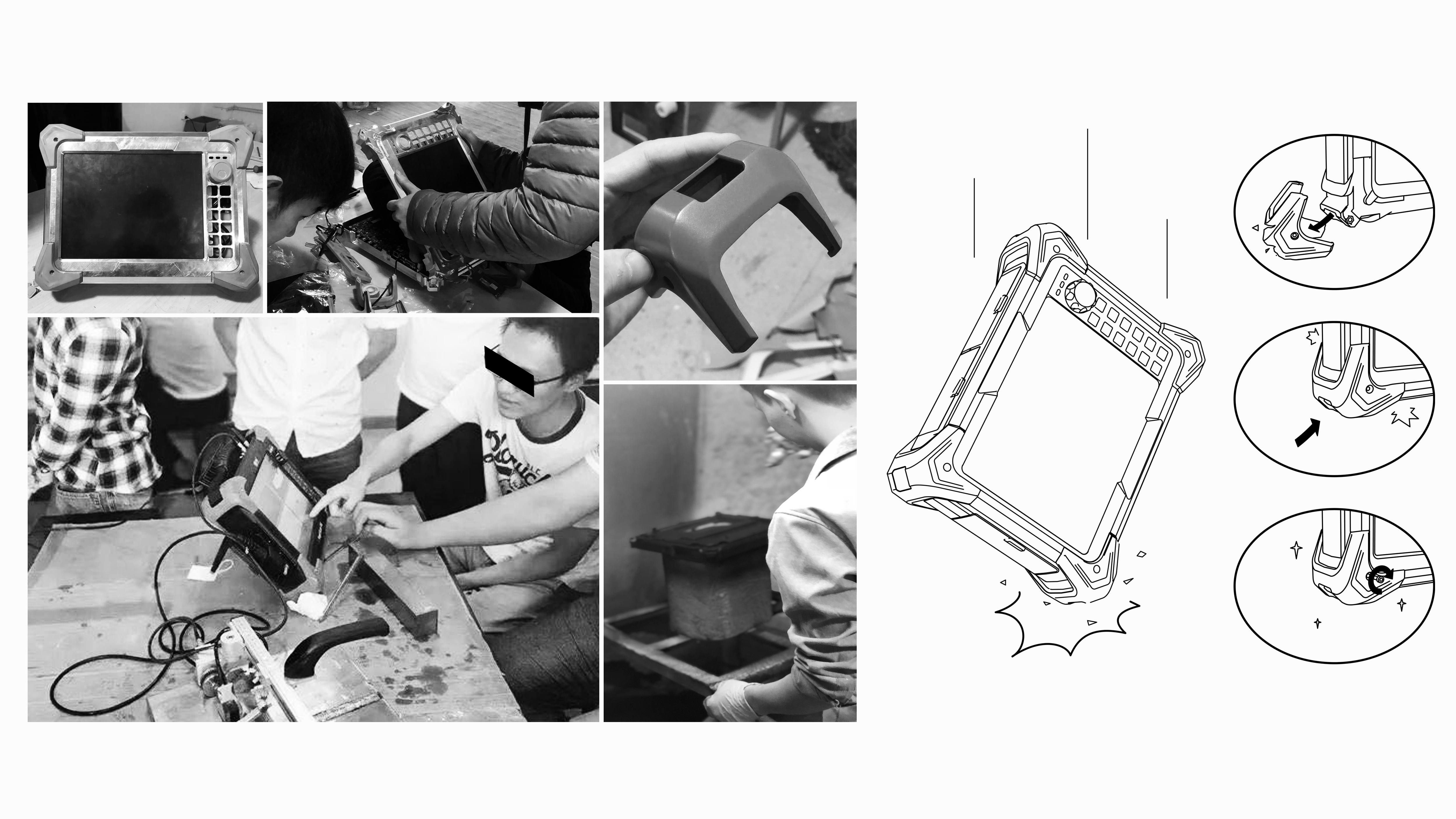

The main body of the product is made of aluminum alloy, which facilitates heat dissipation and is matched with four corner protectors to enhance the strength of the product and enable it to cope with various complex environments.

The main body is made of aluminum alloy, which is convenient for heat dissipation and equipped with four corners to improve the strength of the product, and it can be used to meet various complex environments.

The copyright of this work belongs to 330ml. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Mmm!

Mr. Jiang's good technique

What the hell

It's kind of interesting.

good job

Not the kui is the third master

Not the kui is a teacher Jiang, the design is very nice

Mr. Jiang, not so good

Outdoor design, praise!

It is very similar to the Trojan horse design recommended below.

It's great. It can help people solve problems.