HL400F earplug dispenser

HL400F Earplugs Dispenser

Products Personal Protection Products 4 0 2017-08-24

Praise (0) Collection (0) Sharing (0):

Details of works

Chinese/English

Brief introduction of works

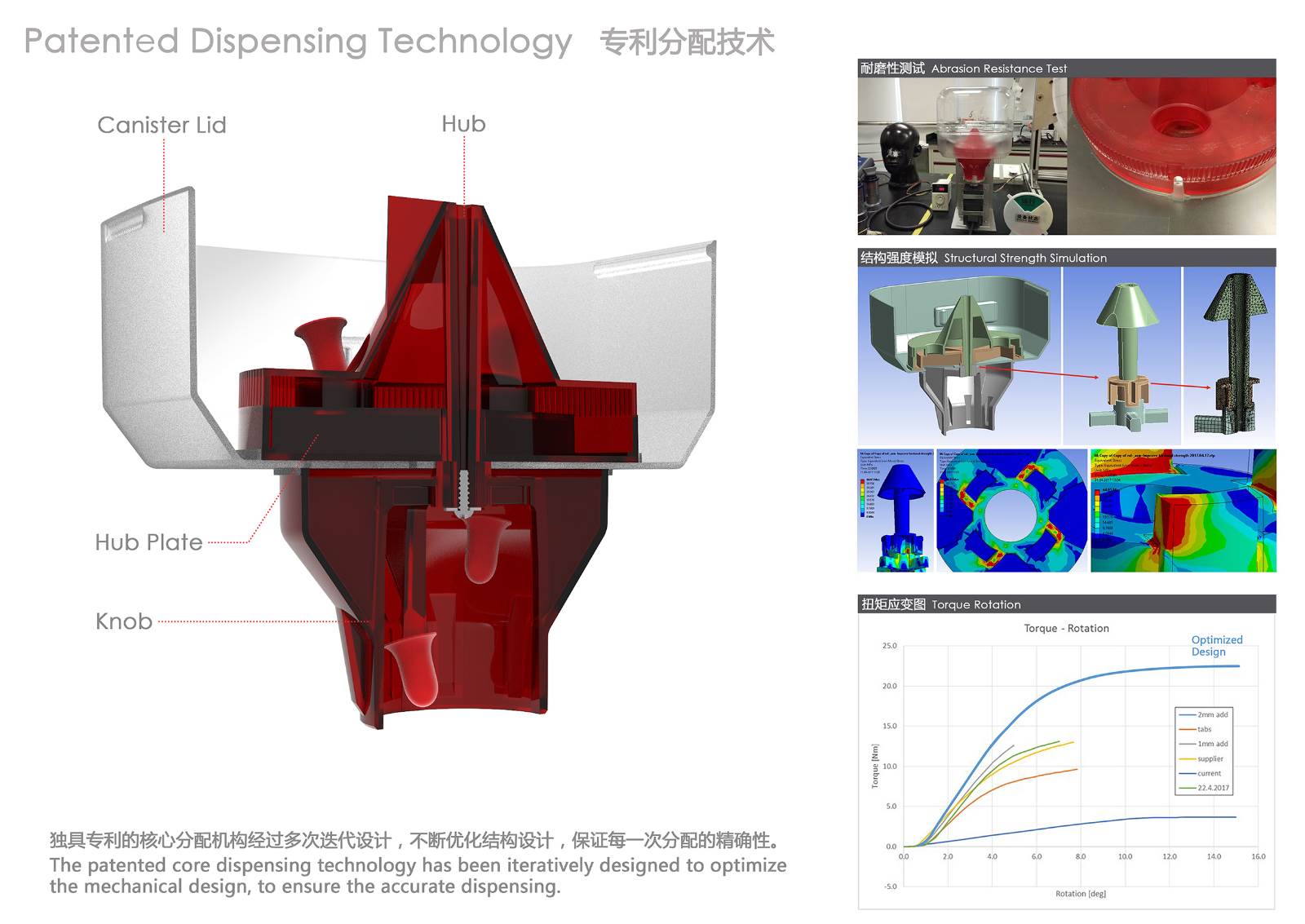

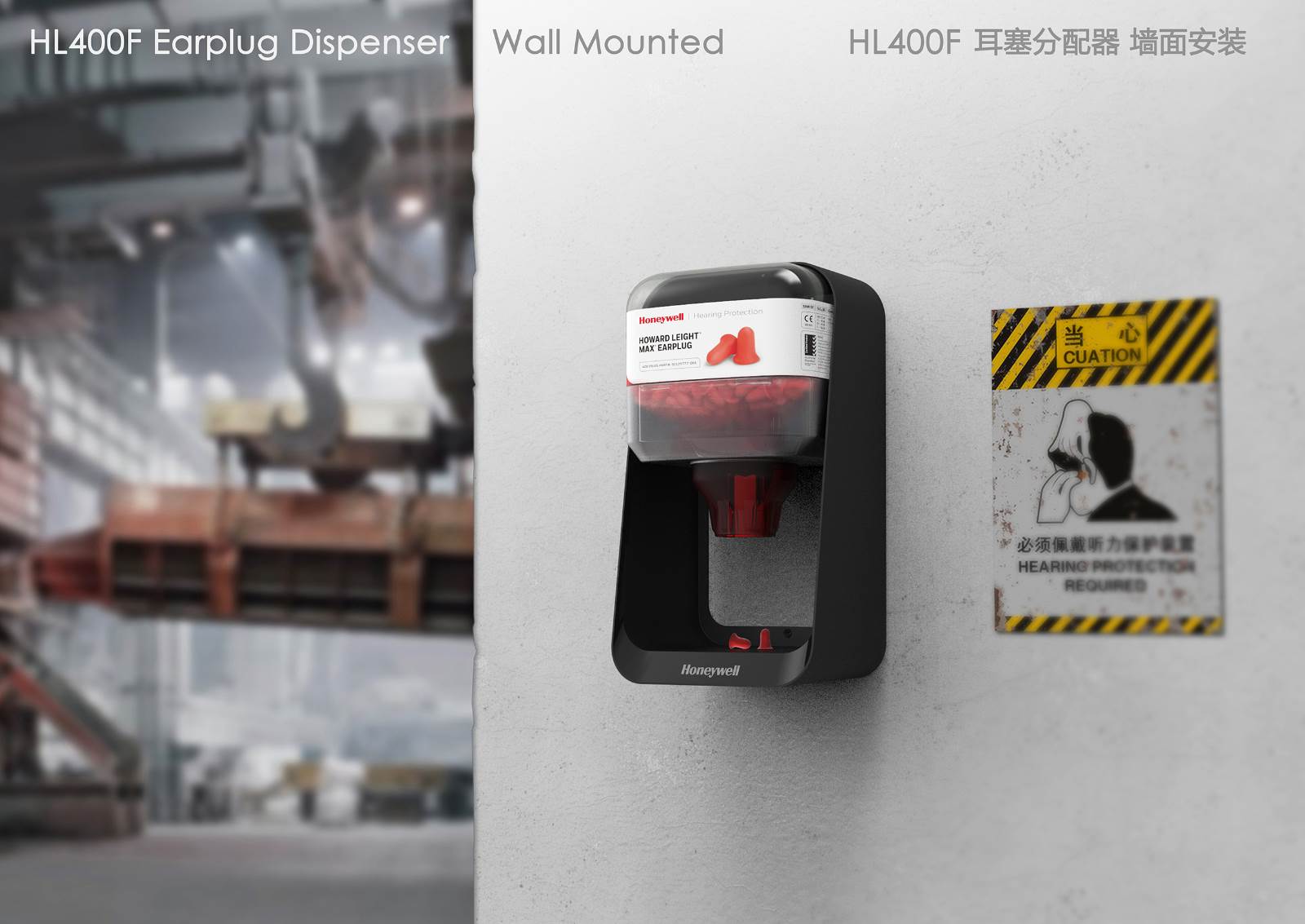

HL400F is a universal noise reduction earplug dispenser, which can be adapted to up to 9 different types of noise reduction earplugs in Honeywell's hearing protection product line. The simple and modern design style of HF400F is different from the image of traditional bulky industrialized products. Its patented technology and excellent design ensure higher product reliability, better ease of use, and provide a better user experience.

User value

Honeywell HL400F is a universal noise reduction earplug dispenser, which can be compatible with up to 9 different types of noise reduction earplugs. At the same time, it can be compatible with desktop placement and wall installation. Technology alone cannot meet the needs of users. The stacking of functions is easy, but it is extremely challenging to be simple and practical. This product integrates design and technology, and considers all aspects of modeling, use, performance, and reliability. All-round consideration of modeling design: the unique, soft and overall modeling of this product gives users friendly and friendly sensory experience, brings warm care in the cold industrial production environment, and achieves the balance of functional characteristics and emotional value. The overall frame design is naturally integrated into various use environments. Whether it is temporary placement of the work surface or long-term fixation of the wall surface, the dark overall frame and red core components continue the Honeywell brand design language, and the transparent tank body and semi-permeable distribution mechanism are convenient to observe the number and distribution status of earplugs. At the same time, the integrated frame design protects the tank body from sunlight, delays the aging of the ear plugs by ultraviolet rays, and greatly improves the overall strength of the product. The structural design of the forward extraction of the tank body minimizes the requirements for installation space compared with the common top installation of similar products on the market. Patent organization ensures accurate operation: this product adopts patented product core distribution organization to ensure accurate earplug distribution and smooth operation. The damping design provides accurate and timely feedback for each rotation of the user. At the same time, the distribution design that takes into account the left and right two-way rotation is a detail concern for a few left-handed users. The most simplified earplug loading: the innovative drawer-type quick loading and unloading tank body makes the loading of earplugs so intuitive and simple. Anti-dull installation design: universal installation backplane design, compatible with most mainstream similar products wall fixing form. In most cases, when replacing similar products, it can be compatible with the previous fixing screw position without re-drilling and installation. Unique process to achieve high reliability: the research and development team and the manufacturer jointly developed the unique injection molding process, to achieve the PC material tank lightweight, but also to ensure the form of rigidity. As a product sold globally, even in the hot and long-term ocean container transportation, it can still ensure the stable performance of the product and the material will not be deformed. Precision mold development ensures the assembly accuracy of soft PC tank and hard ABS tank holder and distribution mechanism, and ensures long service life and stable operation quality of distributor. The minimum part design and integrated frame structure not only make the product have extremely high reliability, but also greatly simplify the daily cleaning and maintenance workload.

Business performance

As a consumable safety protection product, industrial noise reduction earplugs have a rigid demand for continuous exuberance in industrial production. The dispenser canned earplugs have extremely high cost performance and are suitable for long-term batch use by manufacturers. The earplug dispenser ensures the long-term effective storage of earplugs, accurate distribution, and minimizes the consumption of earplugs. The saved consumables and human maintenance are equivalent to directly saving the operating costs of the production enterprise. The HL400F earplug dispenser has greatly increased the sales of earplugs and brought considerable profits to the company. Honeywell Industrial Noise Reduction Earplugs sold more than 1000 million pairs in China only in 2016. Many large domestic manufacturers are customers of Honeywell hearing protection products. Such as Sinopec Group, Daya Bay Nuclear Power Station and Datang Energy.

Hearing damage caused by long-term exposure to noise in industrial production can lead to neurological deafness, which is one of the most important occupational diseases in the world. The total number of occupational groups in China ranks first in the world, so the harm of occupational noise is very serious and has been paid more and more attention by the society. The correct wearing of noise-reducing earplugs in industrial production can effectively reduce the damage of environmental noise to users' hearing, thus protecting hearing health. However, pollution and damage will make earplugs lose their noise reduction effect. On the choice of materials. The tank body is made of food safety grade PC material, which is environmentally friendly and hygienic, has stable performance, and can even withstand a high temperature of 100 degrees. Compared with similar products, the tank can be reused, and the supplementary earplugs are packaged in environmentally friendly degradable cartons to avoid environmental damage caused by excessive packaging.

HL400F is a universal noise reduction earplug dispenser, which can be adapted to up to 9 different types of noise reduction earplugs in Honeywell's hearing protection product line. The simple and modern design style of HF400F is different from the image of traditional bulky industrialized products. Its patented technology and excellent design ensure higher product reliability, better ease of use, and provide a better user experience.

The overall frame design is naturally integrated into various use environments. Whether it is temporary placement of the work surface or long-term fixation of the wall surface, the dark overall frame and red core components continue the Honeywell brand design language, and the transparent tank body and semi-permeable distribution mechanism are convenient to observe the number and distribution status of earplugs. At the same time, the integrated frame design protects the tank body from sunlight, delays the aging of the ear plugs by ultraviolet rays, and greatly improves the overall strength of the product. The structural design of the forward extraction of the tank body minimizes the requirements for installation space compared with the common top installation of similar products on the market. Unique process to achieve high reliability: the research and development team and the manufacturer jointly developed the unique injection molding process, to achieve the PC material tank lightweight, but also to ensure the form of rigidity. As a product sold globally, even in the hot and long-term ocean container transportation, it can still ensure the stable performance of the product and the material will not be deformed. Precision mold development ensures the assembly accuracy of soft PC tank and hard ABS tank holder and distribution mechanism, and ensures long service life and stable operation quality of distributor. The minimum part design and integrated frame structure not only make the product have extremely high reliability, but also greatly simplify the daily cleaning and maintenance workload.

To view product details, please go to http://successfuldesign.org/work/599be2fc593921198f6182c9

The copyright of this work belongs to 成功设计平台. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

It should be a kind of safety equipment used in the factory.

If only there were less words, haha, mainly because I didn't have the patience to read them.