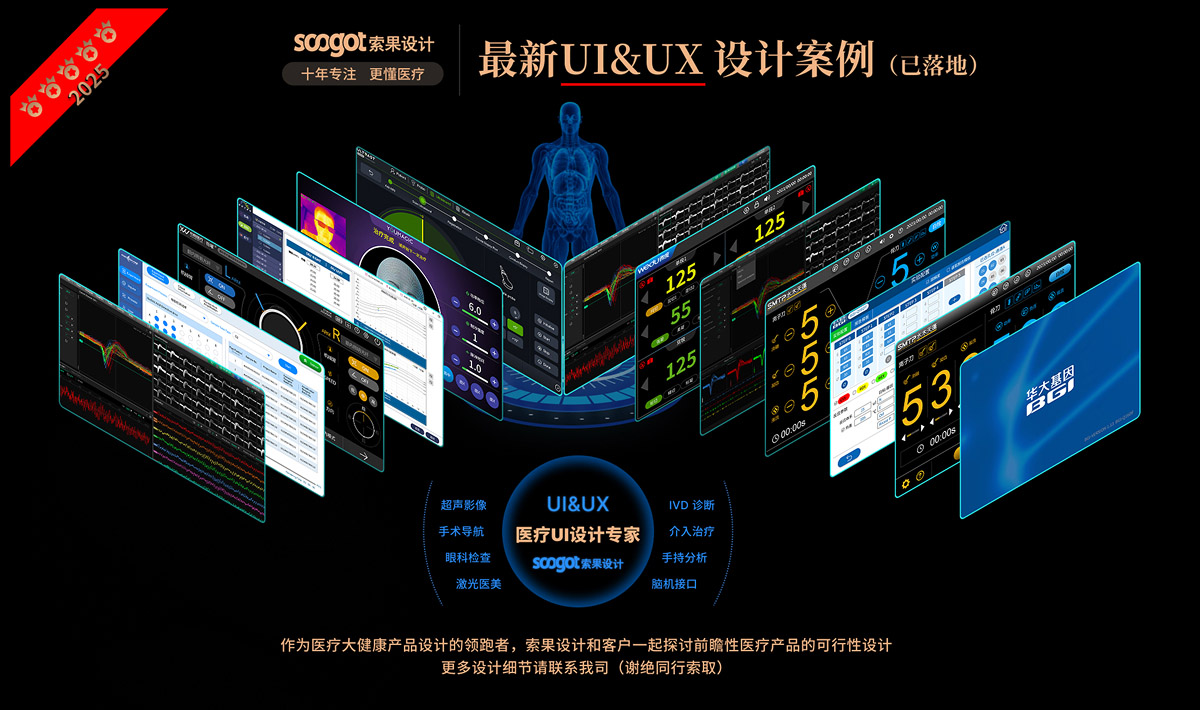

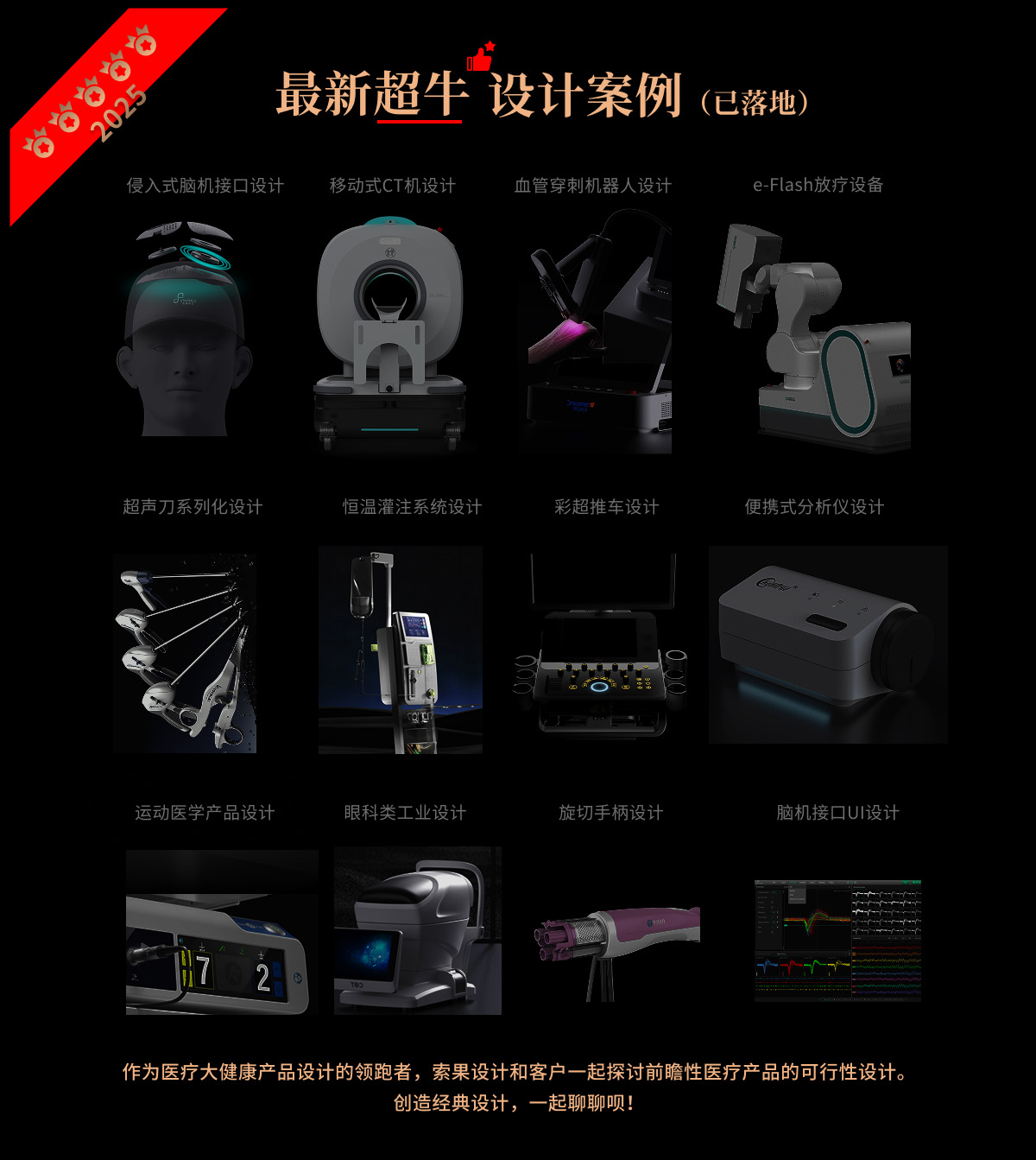

Sogo Design... Ten years of focus on medical health the only track.

Cooperative customers: well-known confidential customers

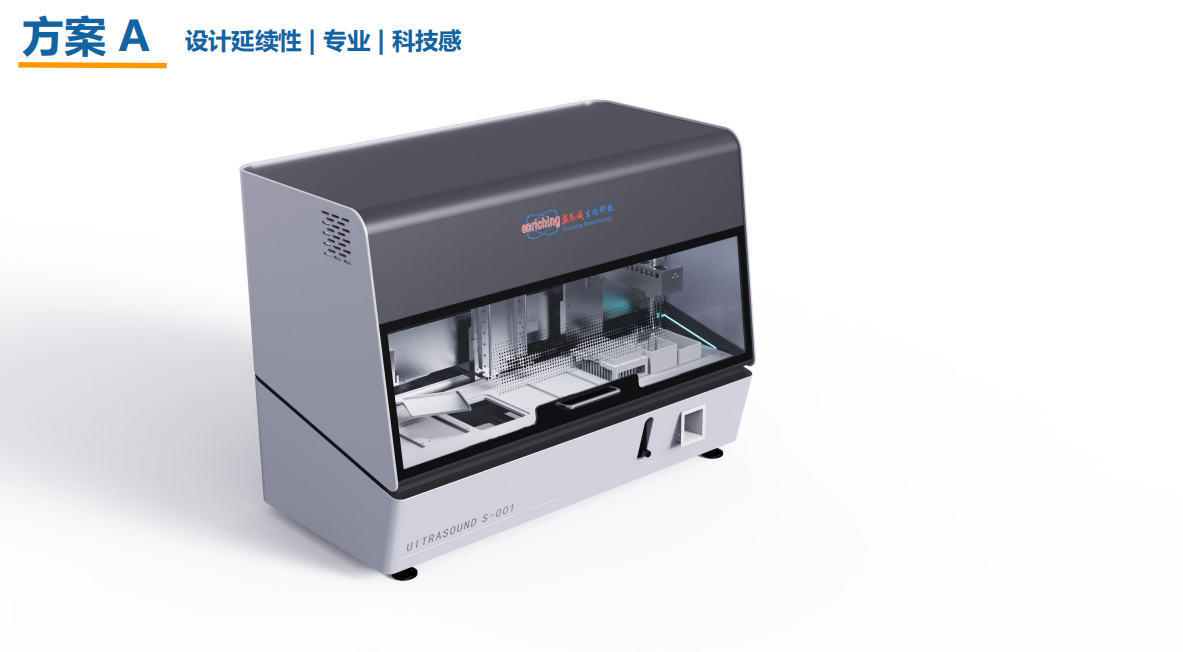

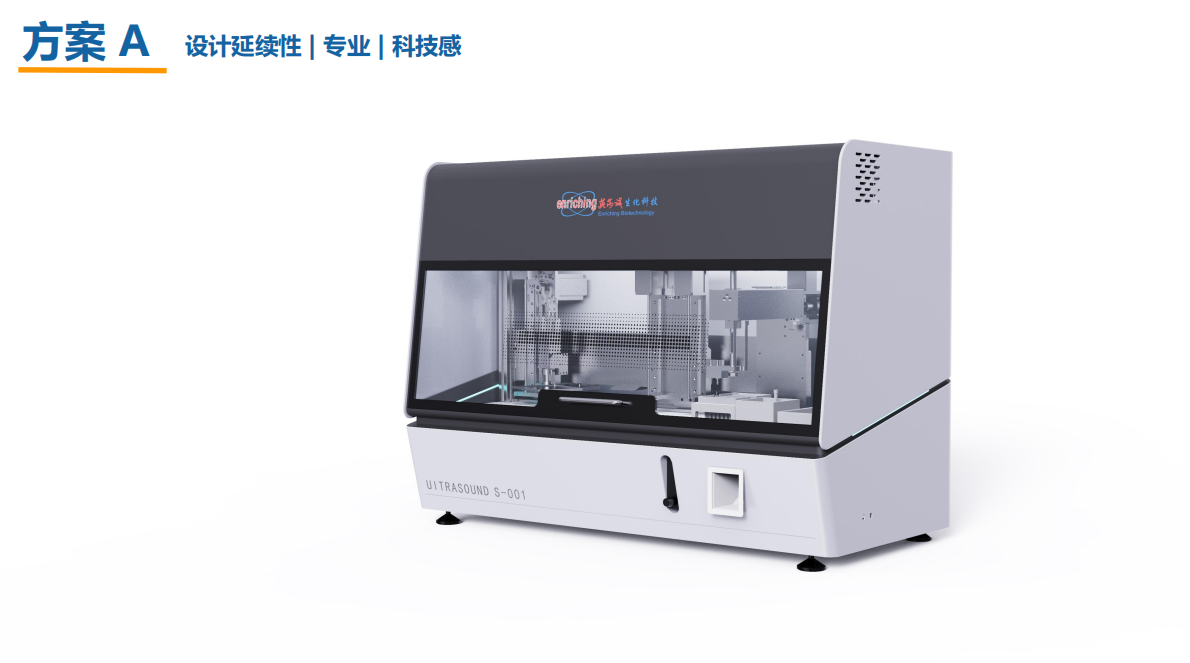

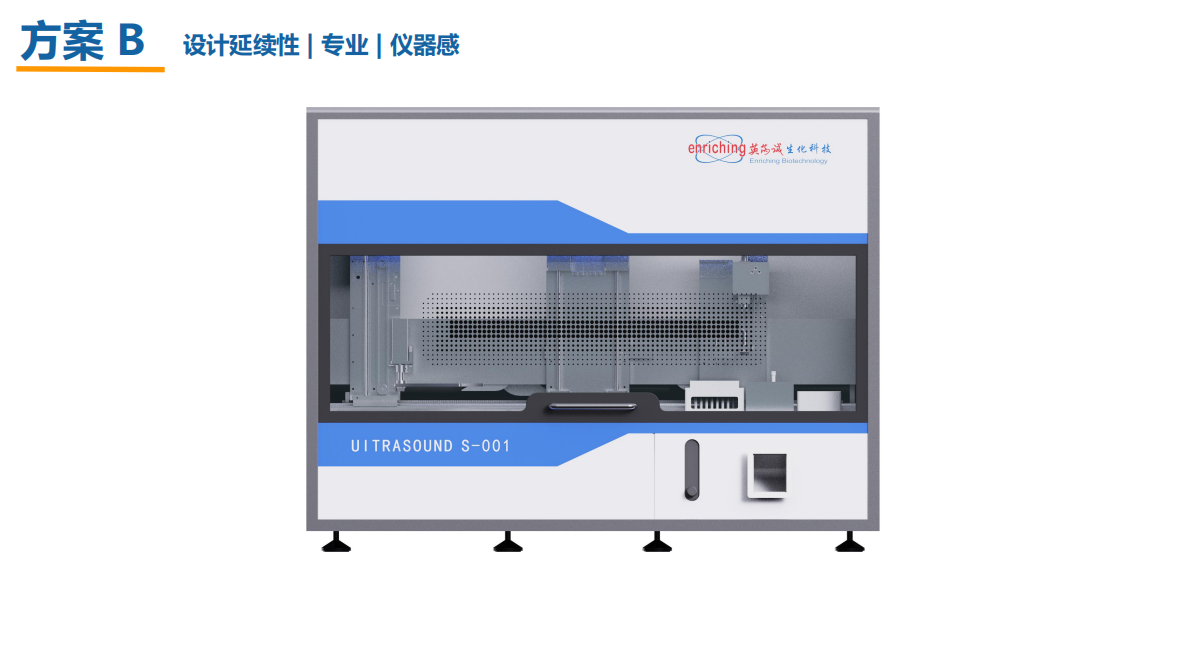

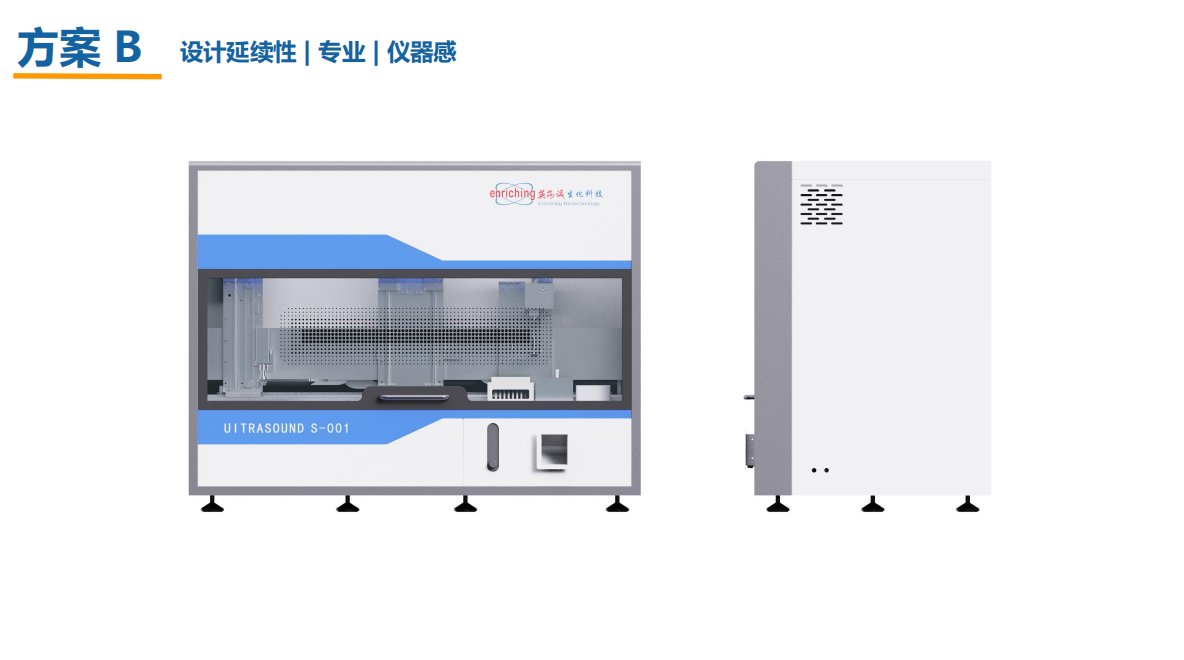

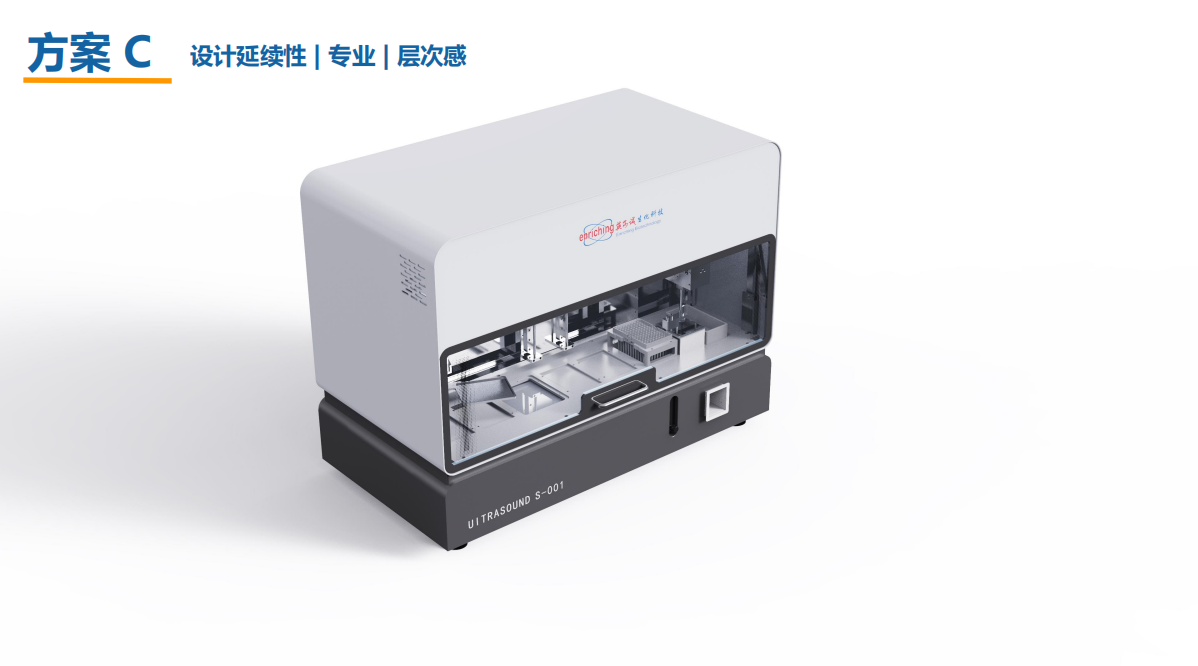

Project Name: Industrial Design of Ultrasound Instrument

Cooperation content: design analysis | appearance design | structural design | prototype production | accompanying running assistance

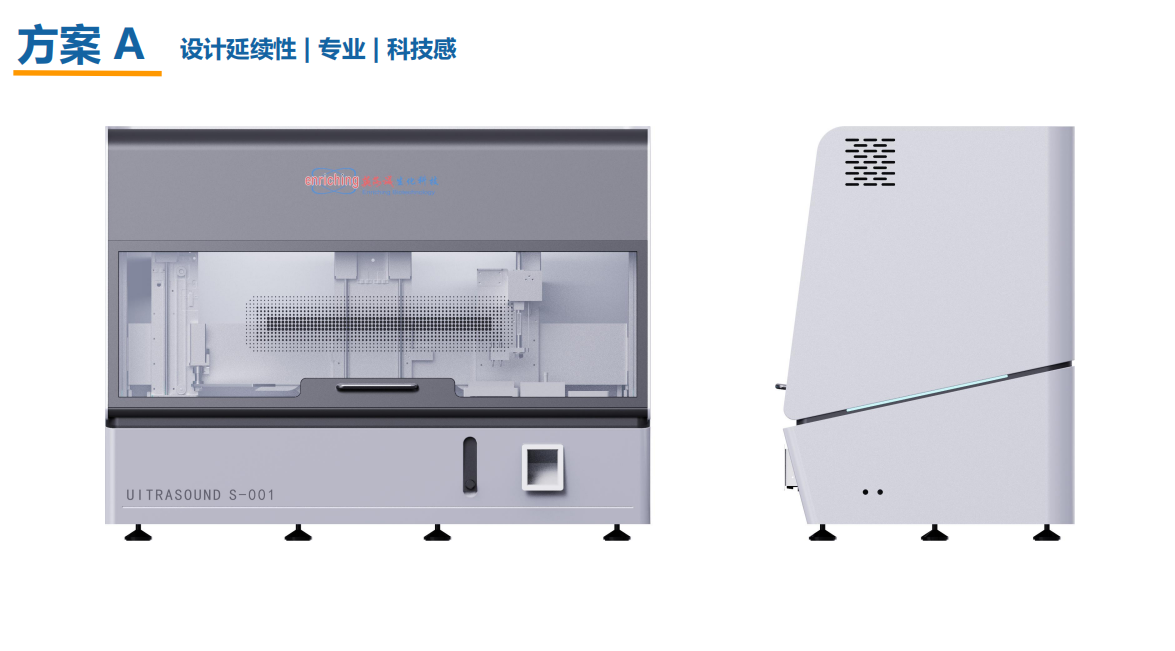

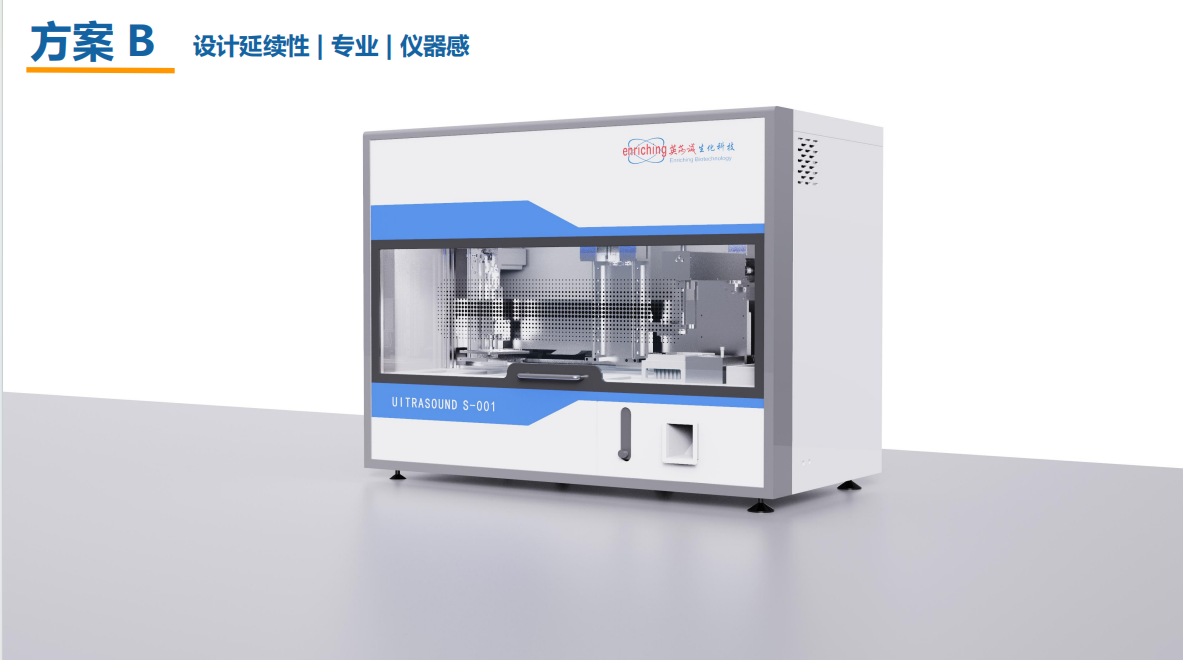

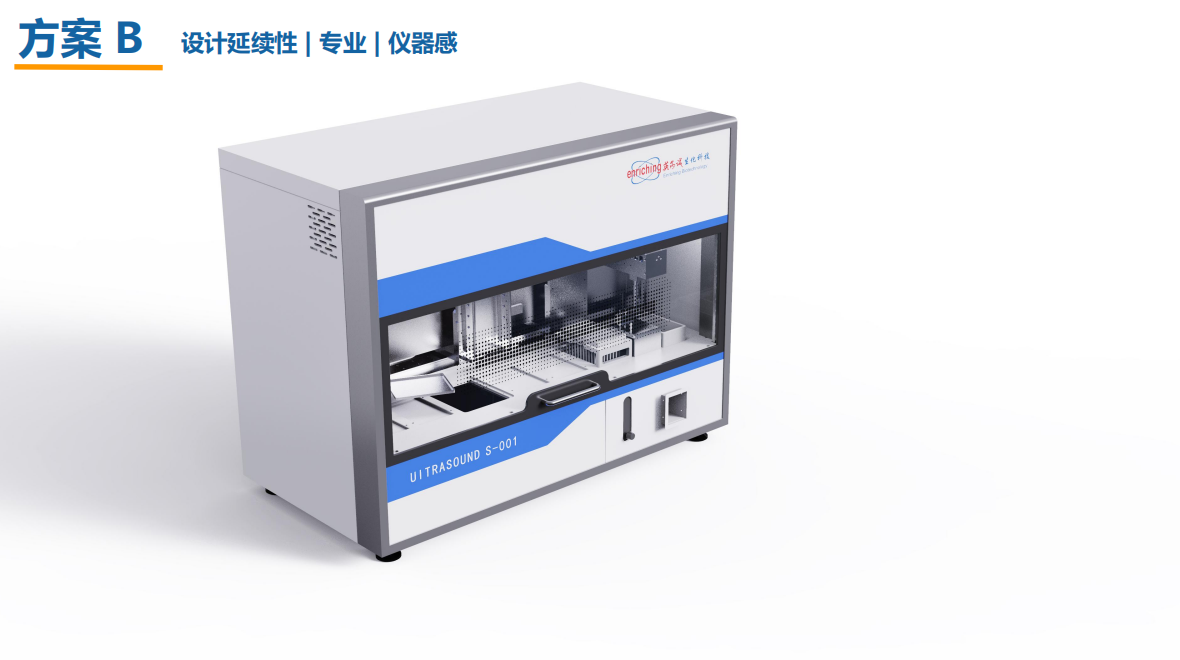

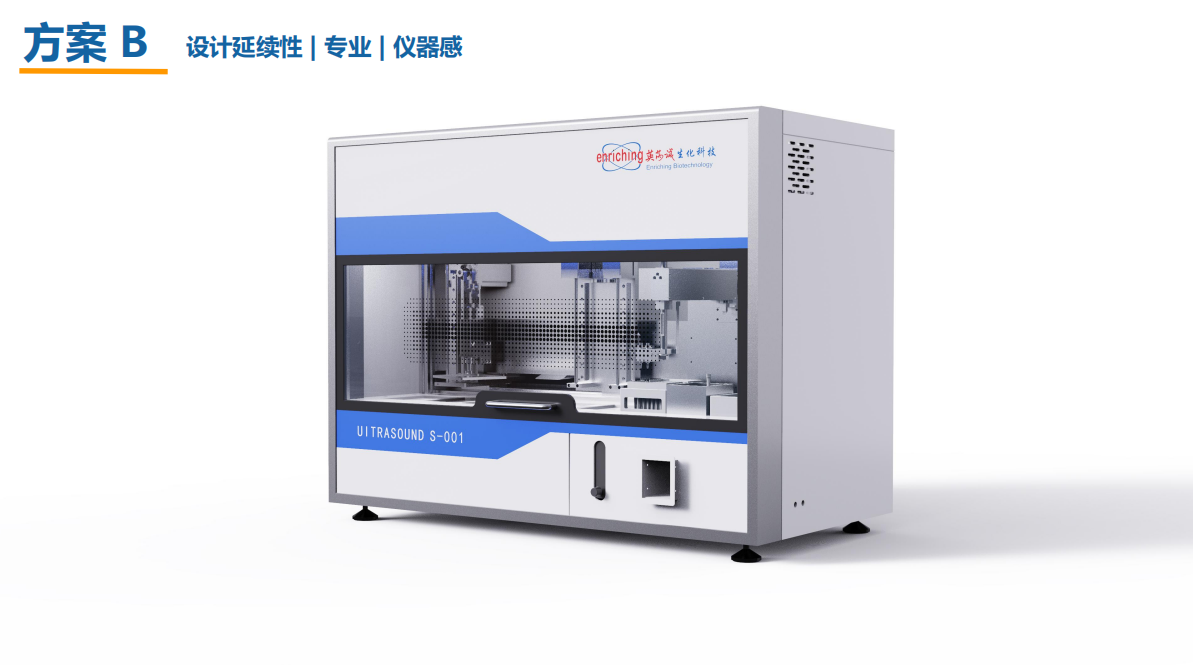

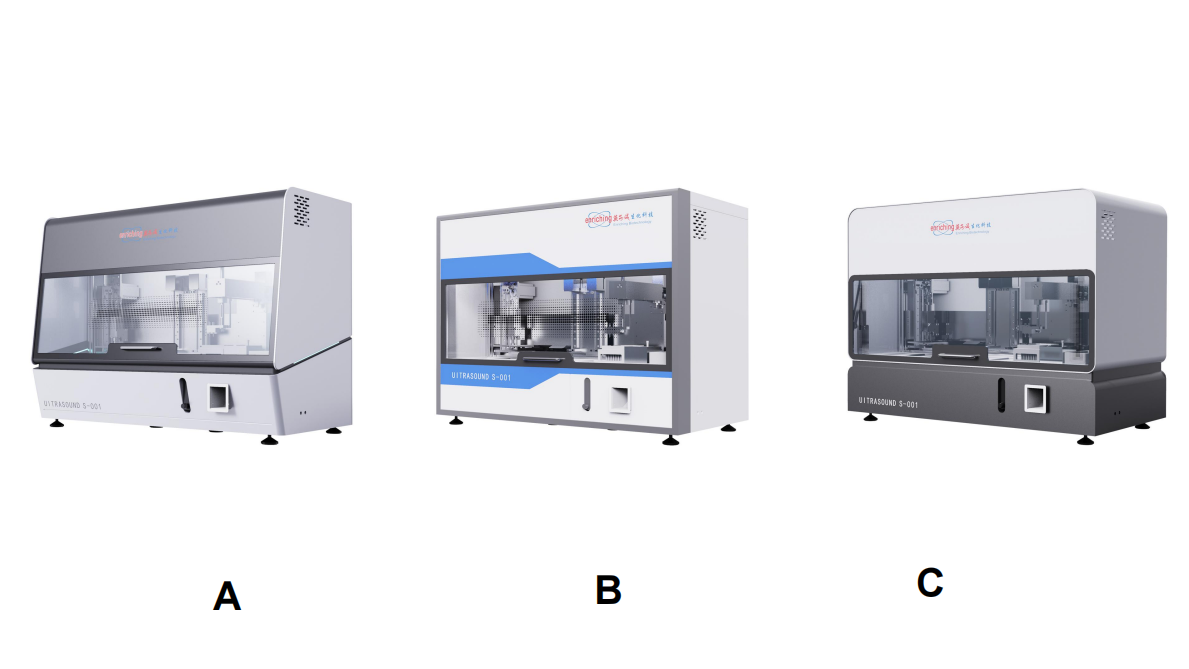

These are three ultrasonic instrument design schemes (A, B, C) for laboratory/medical scenes, positioning automatic ultrasonic processing equipment (such as sample ultrasonic crushing, material ultrasonic detection, etc.), and its design revolves around "the precision of automatic operation and the adaptability of laboratory scenes", realizing differentiated adaptation of different experimental scenes in form, functional layout and details, it is a design sample of "functional rationality" and "scene-friendly" integration of laboratory precision equipment.

1. Design Analysis: Functional Modular Adaptation of Laboratory Scenarios

The core scenario of the ultrasound instrument is automated ultrasound processing in biological laboratories and medical testing rooms, and the underlying logic of the design is centered on "precision automated process laboratory equipment management:

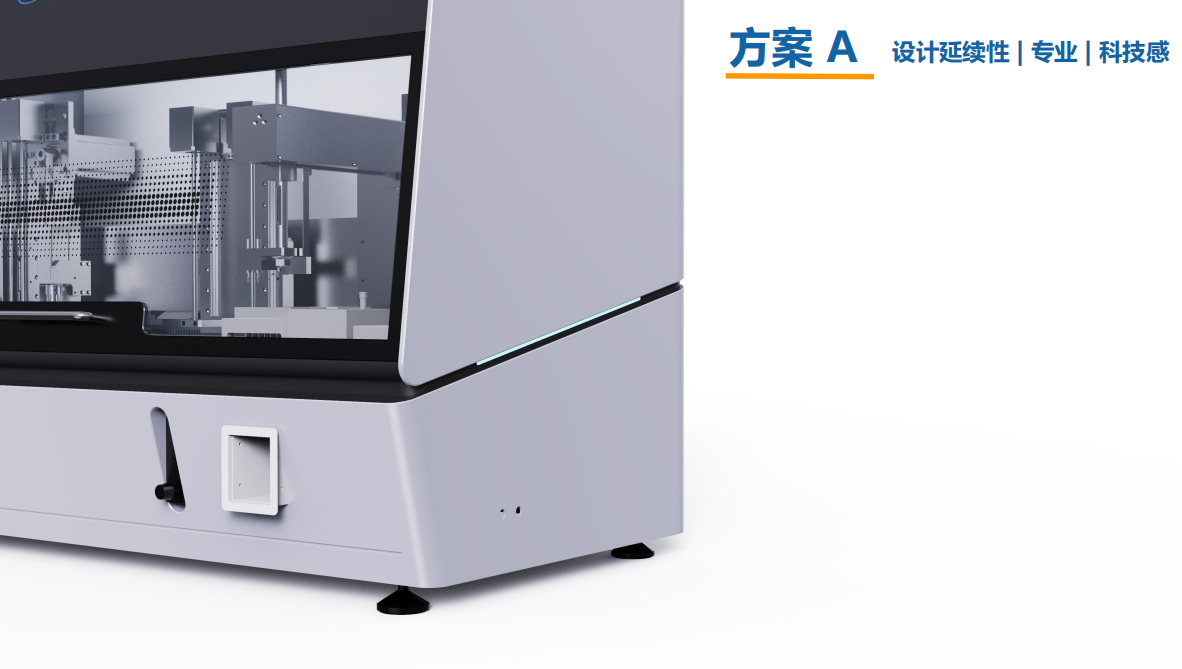

Process adaptation of functional modules: all three schemes integrate the three modules of "transparent operation cabin (observing ultrasonic process), core ultrasonic processing area (main body of fuselage) and equipment interface area (side/bottom)", and conform to the experimental process of "putting experimental samples → starting automatic ultrasonic program → observing the processing process in real time. The transparent operating cabin is the core functional area, which not only ensures the visualization of sample processing, but also avoids sample contamination or splashing during ultrasound.

Scene differentiation adaptation: the three schemes adapt to different experimental requirements through form and color matching:

Scheme A (gray-black matte): suitable for "simple laboratory", low-key form to avoid interference with multi-device collaborative experimental environment;

Scheme B (blue and white color contrast): suitable for "batch sample processing scene", high recognition color matching is convenient for laboratory personnel to quickly locate equipment;

Scheme C (gray-white layering): Adapt to "high-frequency precision operation scenarios" and convey high-reliability perception of the device in a stable form.

Laboratory properties of materials: the combination of "laboratory-grade corrosion-resistant plastic high-permeability acrylic cabin" is adopted. The corrosion-resistant plastic is suitable for common reagent environments (such as buffer solution and organic solvent) in ultrasonic treatment, and its easy-to-clean characteristics conform to the laboratory's cleanliness management standards. The high-permeability cabin ensures the clarity of observation and does not affect the judgment of the sample state by the experimenters.

2. Design Language: Rational Aesthetic Expression of Precision Tools

The design language of the three schemes is based on the common tone of "rational precision", and the scene attributes are conveyed through the differences in details:

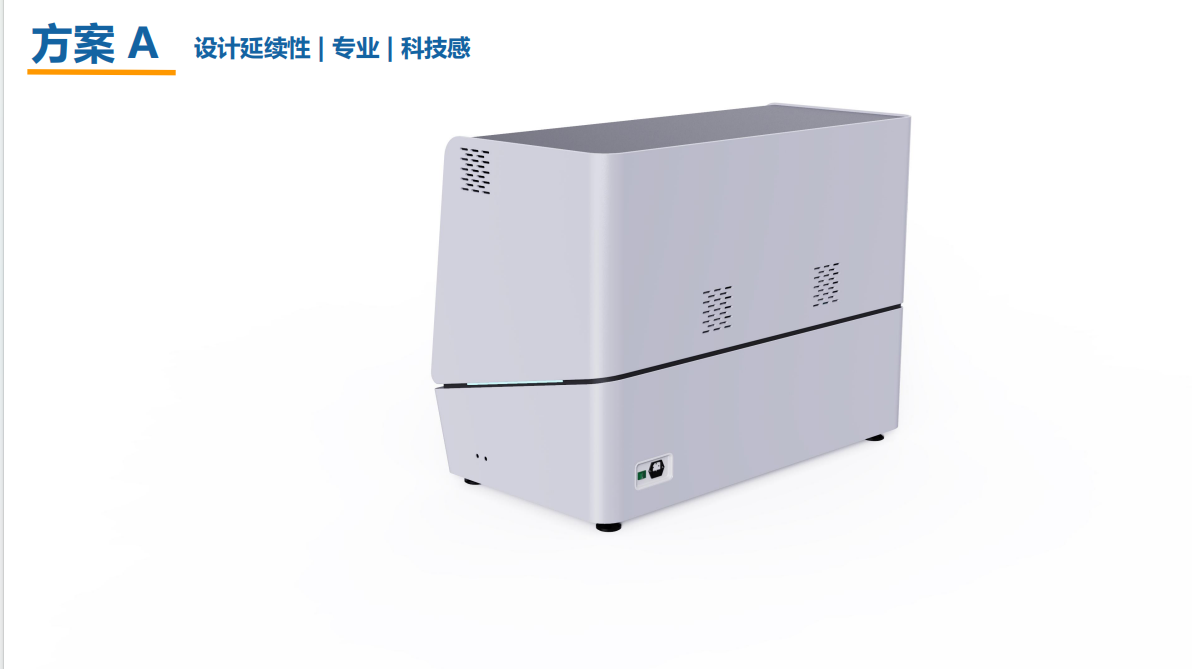

Commonality: Instrumental precision aesthetics: all adopt the form of "simple geometry without redundant decoration", with regular lines and rounded corners, which not only convey the "rigor" of laboratory equipment, but also avoid potential operational safety hazards caused by sharp structures. The overall form is compact and adapts to the space layout requirements of the laboratory table.

Differences: Scenario style breakdown:

Scheme A: gray-black matte color matching integration form, transferring the "low-key and simple" style, and adapting to experimental scenes with low requirements on visual interference of equipment (such as molecular biology laboratory with multi-equipment parallel);

Scheme B: Blue and white contrasting color line segmentation, strengthening the visual distinction between the operation cabin and the fuselage, and high recognition color matching is convenient for batch equipment management (such as equipment partition of large testing laboratory);

Scheme C: Gray-white layered stable lines, conveying the "high reliability and precision" style, suitable for high-frequency operation scenarios requiring high equipment stability (such as sample pretreatment in drug research and development laboratories).

3. Design Details: Implicit Support for Precision Operation

The detailed design revolves around the "precision of ultrasonic processing and laboratory management requirements" to accurately solve the experimental pain points:

Details of transparent operation cabin: "highly permeable and distortion-free acrylic material" is adopted to ensure that the experimenter can clearly observe the ultrasonic state of the sample (such as bubble generation and sample dispersion degree) and avoid affecting the experimental results due to visual errors. The sealed connection between the cabin and the fuselage reduces the volatilization of the sample or the intrusion of external dust during the ultrasonic process, thus ensuring the cleanliness of the experiment.

Details of equipment stability: the bottom is equipped with "anti-skid shock-absorbing support feet", which will produce high-frequency vibration during ultrasonic treatment. The shock-absorbing feet can reduce the shaking amplitude of the equipment, not only avoid the sample container from toppling, but also reduce the interference of vibration to other equipment on the laboratory table.

Functional auxiliary details: a "hidden heat dissipation grille" is set on the side, ultrasonic treatment (especially long-term operation) will generate heat, the heat dissipation grille ensures the stable operation of the internal components of the equipment, and prevents temperature abnormalities from affecting the stability of ultrasonic power; The "model brand logo" on the front/side of the fuselage is clear and easy to read, which is convenient for the classification, registration and maintenance management of laboratory equipment.

4. Ergonomics: Comfortable Adaptation for Laboratory Operation

The ergonomic design of the three schemes is optimized for "standing operation of experimenters and multi-device collaboration:

Adaptation of observation angle: the height and angle of the transparent operation cabin are in line with the head-up angle of view of "laboratory standing operation". The experimenter can clearly observe the internal sample state without bending down or standing on tiptoe, thus reducing the fatigue of neck and waist in long-term experiments.

Adaptation of operation space: the width and depth of the fuselage are adapted to the conventional layout of the laboratory table top, and sufficient hand operation space is reserved between adjacent equipment, which is convenient for the taking and placing of sample containers and the rapid debugging of equipment.

Equipment cooperative adaptation: the interface area (such as power supply and data transmission port) on the side/back of the fuselage is designed on the non-operation side to avoid wiring interference with the operation lines of the experimenters and adapt to the laboratory scene of multi-equipment parallel.

Conclusion: Scenario samples of laboratory precision equipment

The design of these three ultrasonic instruments is a symbiotic sample of "precision function" and "scene adaptation" of laboratory automation equipment. It supports the core process of ultrasonic processing with modular design, transmits the rigorous attributes of laboratory equipment with rational aesthetics, optimizes the details to ensure the accuracy of operation and the convenience of management, and adapts the operation habits of experimenters with ergonomics.

With the increasing demand for laboratory automation, this design not only improves the efficiency and accuracy of ultrasonic processing, but also redefines the value of "laboratory precision equipment"-it is no longer a universal tool, but a "precision collaboration partner" customized for different experimental scenarios ". This concept of "driving design differentiation by scene subdivision" also points out the direction for laboratory equipment design: only by going deep into the real needs of experimental scenes can we create precision tools that really help scientific research and testing. Sogo Design: www.soogot.com

The copyright of this work belongs to 索果设计-专注医疗大健康设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Meet the health requirements of the medical environment

Meet the needs of different medical institutions and patients

Professional Design