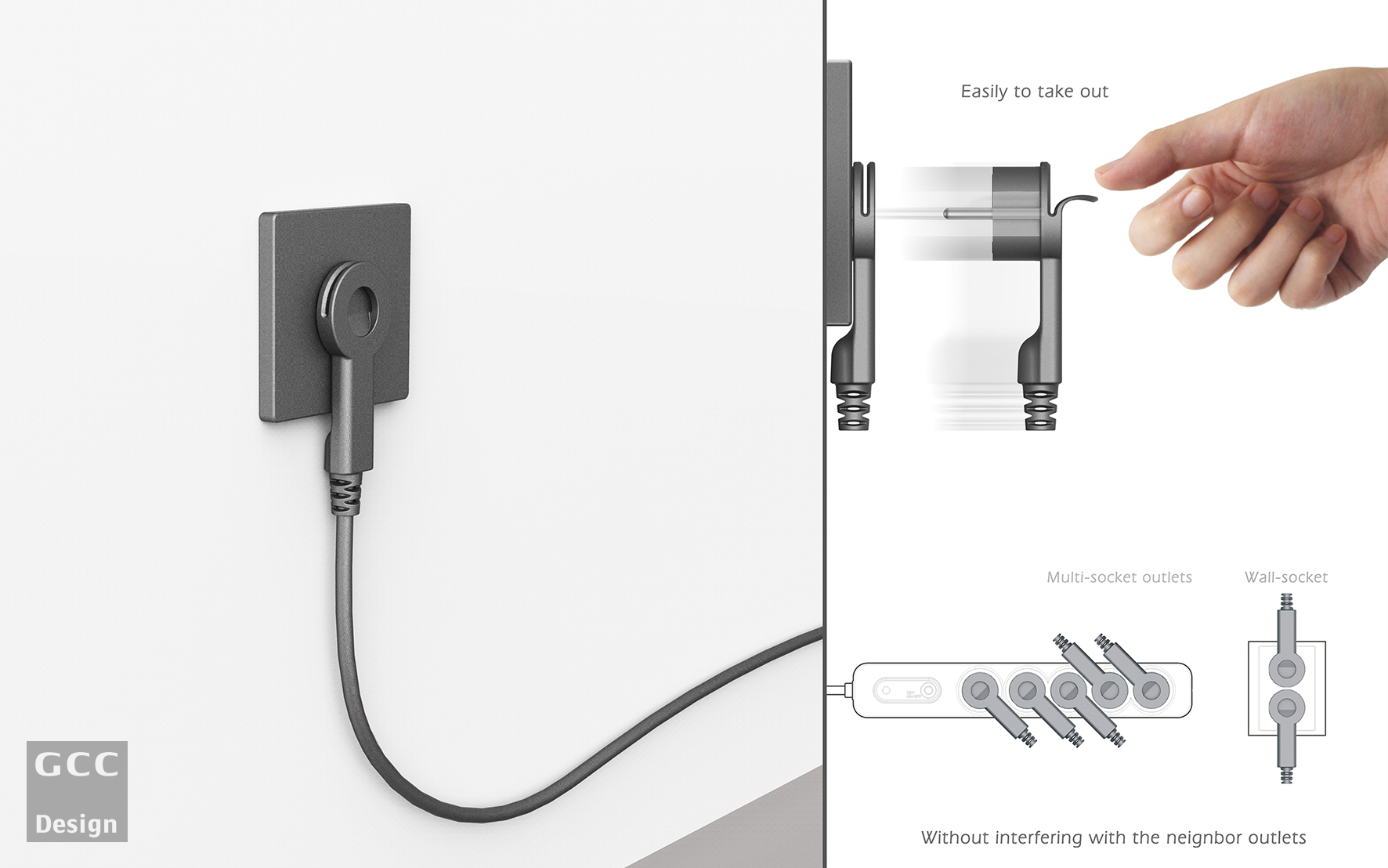

Plug improvement project designed for foreign trade customers. How to reduce costs while improving the experience?

Easy to pull out. We have accomplished this important function with the most mature process. When the plug was injected for the second time, we innovatively made the tpr material form a local sheet. This deformable tpr suspension wall is enough for people to hold and pull out the plug smoothly. After release, the elasticity of tpr can return to the sheet state. The process of this process is the process of traditional plug. The mold design is simple and will not increase the mold and processing costs.

Subtract the excess volume. We limit the thickest exposed size of the product to 10mm, which is consistent with the thickness of the "skirting line" in the corner. Therefore, furniture or objects placed against the wall will not be disturbed. At the same time, we subtract the excess volume around the plug, so that the adjacent jacks can also be undisturbed and improve the usage rate of the socket.

Because there is no assembly process for direct injection molding, there is no labor cost. The innovative design has reduced the material from the original 100g to the current 60g. In addition to reducing costs, reducing the use of raw materials and shortening processing time due to reduced volume, all reduce the burden on the environment.

The design is simple, convenient and easy to use, and improves the cost performance. This product has received a large number of orders.

The copyright of this work belongs to 矩成创意. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Local bosses don't know if they have a chance to cooperate.

This requires that the material is better and can withstand pulling.

This is very interesting