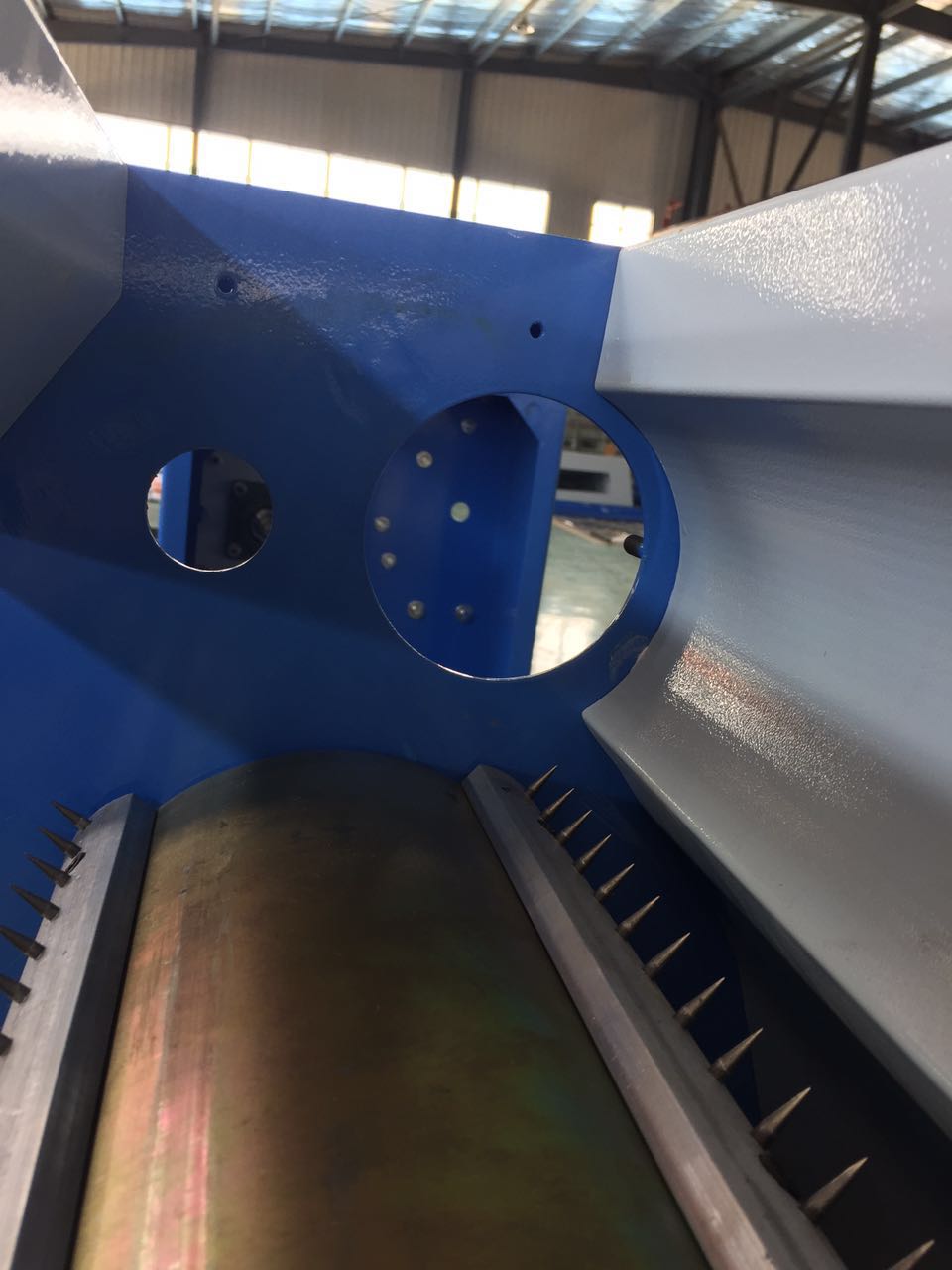

The device mainly consists of: cotton roller, cotton roller shaft head, cotton box wall panel, anti-winding disc, fixing screw, etc. The anti-winding disc is made of special materials. The principle of the device is that when raw material fibers enter the middle of the two rollers and move down with the rotation of the rollers, a small part of the fibers will rotate to the roller shaft head. As the shaft head rotates, it is continuously wound on the roller shaft head, and the more it is wrapped, the more it is until the gap between the shaft head and the wall panel is filled. Finally, the roller shaft head is squeezed or broken. If the anti-winding device is used, the fiber is blocked outside the anti-winding disc. Since the anti-winding disc is fixed on the wall board and does not rotate with the roller, and although the roller shaft head rotates, it is wrapped in the disc and the fiber cannot be wound close to it, thus fundamentally solving the phenomenon of fiber winding roller.

After the device was developed and produced, it was first used in experiments in a large spinning mill in Shandong, the company's customer. Through experiments, different fiber raw materials were repeatedly replaced, and the design was continuously improved to achieve the optimal design scheme. Finally, the problem of winding rollers with acrylic and other filament fibers was solved. Not only did it not need to stop for cleaning every shift, but also the product quality was improved. First of all, it was recognized and praised by the front-line operators in the workshop, as well as the personnel in the workshop process and quality monitoring departments. In the end, all the combing cotton boxes were replaced with this structure, and gradually promoted. Finally, it has been recognized and praised by our customers.

In the future cotton box production, our company all replaced it with such a device. Although it increased a certain cost, it brought convenience and benefits to customers. Finally, it solves the problem that the comber is fed to the roller shaft head in the cotton box. The comber is fed to the roller shaft head in the cotton box, which not only brings product upgrades and technological progress to the vast number of spinning enterprises. More importantly, it has solved the technical problems over the years and greatly improved the spinning quality. This technology is not only suitable for the new cleaning and carding system, but also can be upgraded for the old cleaning and carding system, so it is a technology worthy of popularization and use.

For details, please go to: http://successfuldesign.org/work/596f0accf33fd5254932b2f7

The copyright of this work belongs to 成功设计平台. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Comment Board (0)

Empty comment