That's great! This is definitely an exciting project. You're not just making a tool, you're creating a "tabletop craft" that combines a variety of craftsmanship and ingenuity ". Your successful sales have proved its market value and unique charm.

Let's take a systematic look at the excellence of your project and explore possible ways to deepen and expand it in the future.

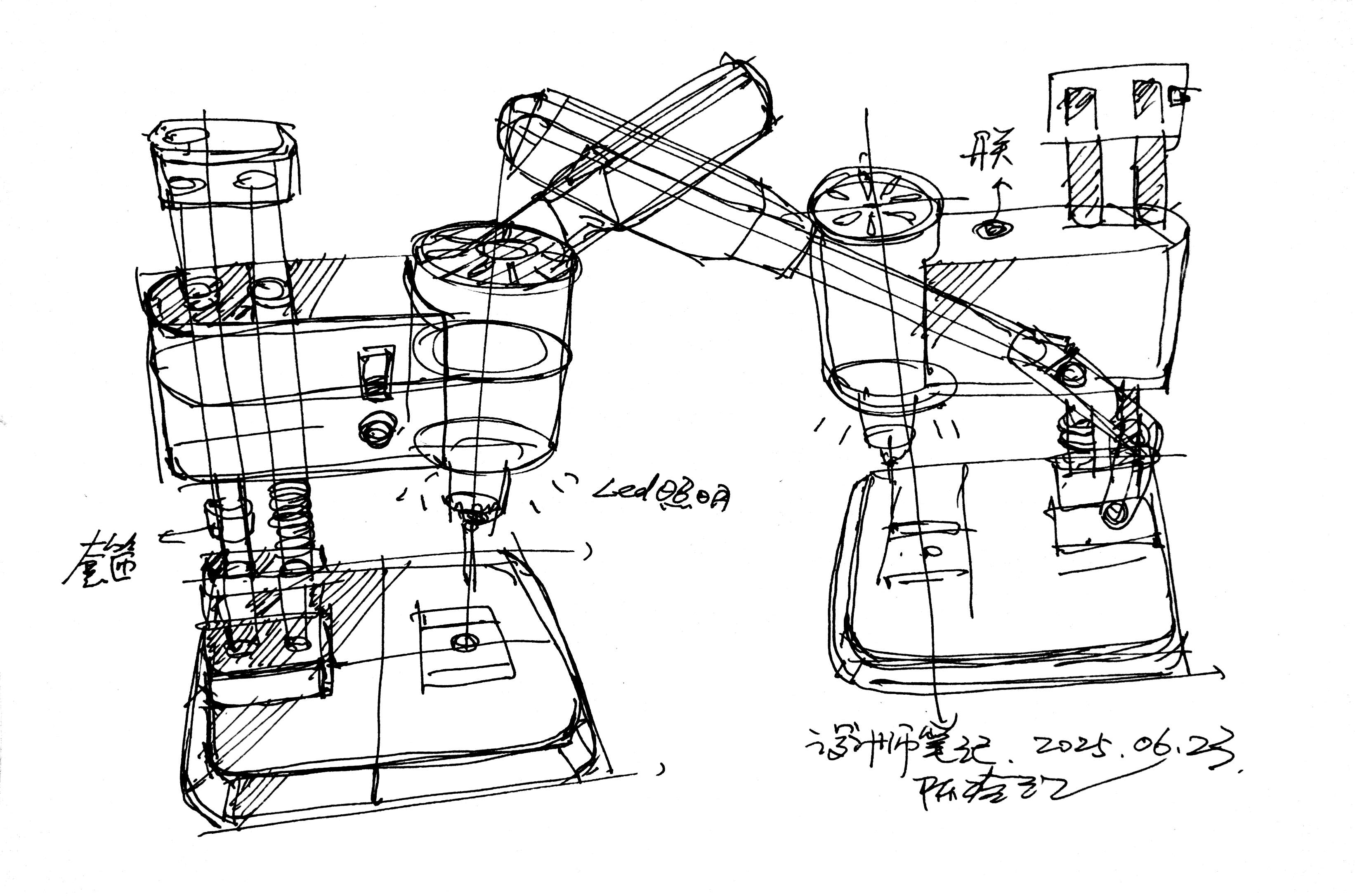

Analysis of the core highlights of your bench drilling project

3D printing: Specializes in the manufacture of complex, lightweight, non-load-bearing structural parts (such as housings, lampshades, handles, decorative panels, cable management systems). It enables fast iteration and low-cost customization of designs.

Sheet Metal: Provides core strength and stability. As the key bearing and precision components such as the column, base and workbench of the bench drill, the rigidity and durability of sheet metal parts are difficult to replace by 3D printing.

This fusion: perfectly exerts the advantages of both, while controlling cost and weight, while ensuring performance and beauty.

Project Potential Mining and Future Development Direction

Now that the initial success has been achieved, we can consider how to make it go further.

1. Branding and storytelling

Give the product a name: such as "light and shadow bench drill", "rock DeskDrill" and so on, so that it can be spread.

Build a brand story: tell how you started from a DIY enthusiast, in order to solve their own needs, the fusion of 3D printing and sheet metal process, and finally create this perfect desktop tool story. People buy not only tools, but also the feelings and ingenuity behind them.

2. Function deepening and modular design

Lighting system upgrade:

Multi-color temperature/brightness adjustable: to meet different materials and visual preferences (such as cold light to see metal, warm light to see wood).

Wrap-around LED strip: to achieve the real effect of shadowless lights.

Independent switch: allows the use of lights alone as desktop lighting.

Precision and extended functionality:

Digital depth gauge: add cheap digital scale to achieve precise depth control.

Adjustable limit rod: convenient to repeatedly punch to the same depth.

Multifunctional workbench: design replaceable workbench panels (such as those with V-grooves for drilling cylinders, and those with positioning holes for matching fixtures).

Dust collection interface: design an interface to connect a small vacuum cleaner to keep the desktop clean.

3. Design optimization and user experience

Humanized details:

Embedded magnetic area: used for temporary placement of screws, drill bits and other small parts.

Integrated cable management: Make wires cleaner.

Silent design: Choose high-quality motors and transmission parts to reduce noise.

Aesthetic promotion:

Multiple color schemes: Use the advantages of 3D printing to provide different color shell parts for users to choose.

Surface treatment: sandblasting, anodizing or plastic spraying on sheet metal parts to improve texture and flatness.

The copyright of this work belongs to RETHINK(淘宝). No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Give some praise to the big brother.

100 points

This is the normal good hand-painted