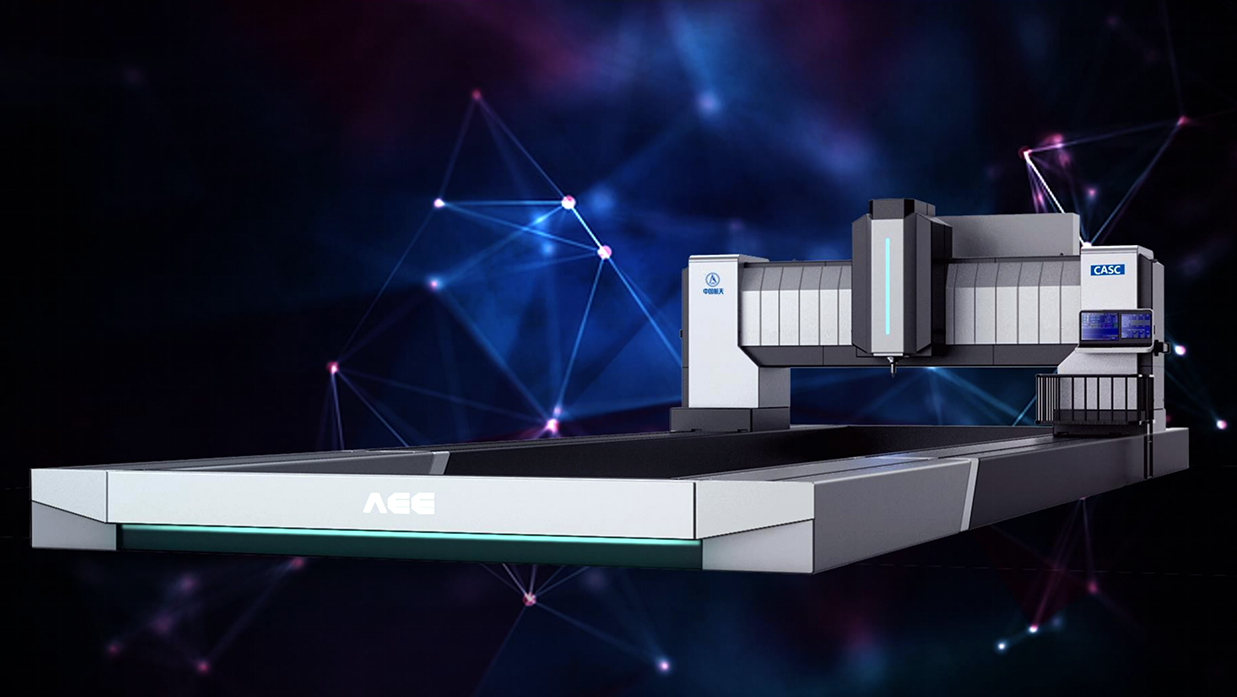

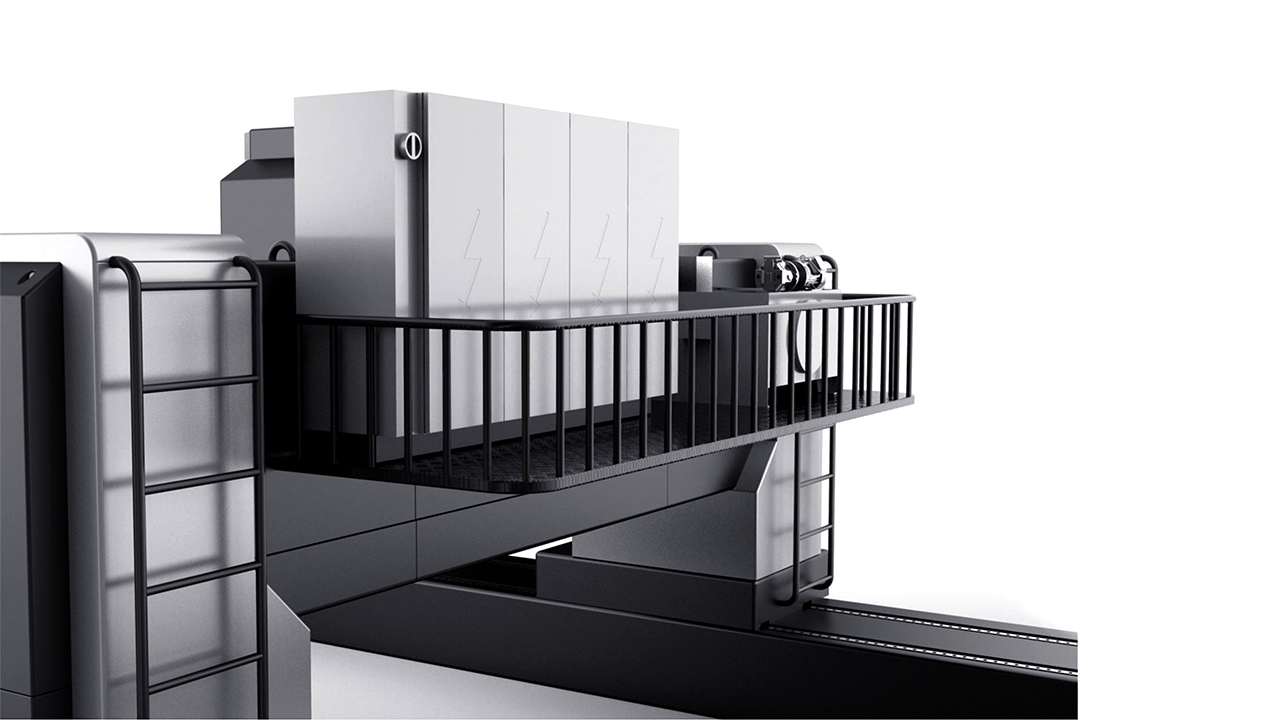

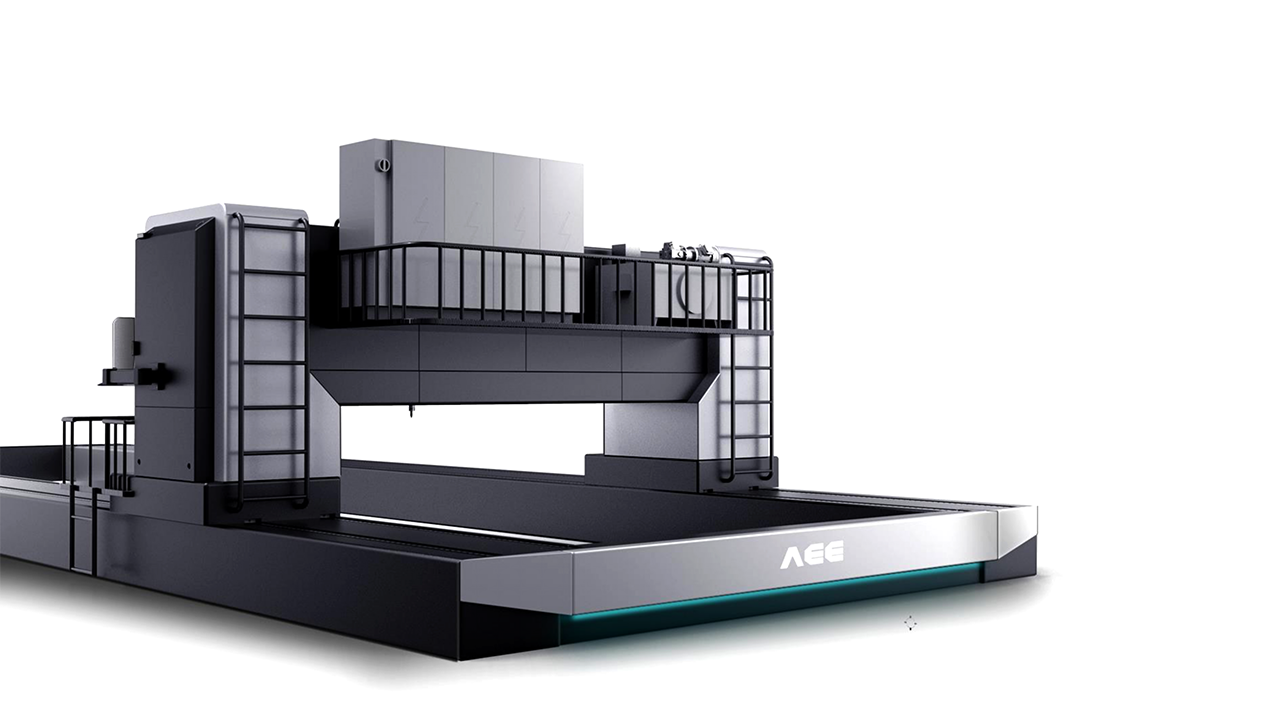

DYNAMIC GANTRY

Aerospace equipment heavy load moving gantry friction stir welding equipment

Design Studies/Industrial Design

2019

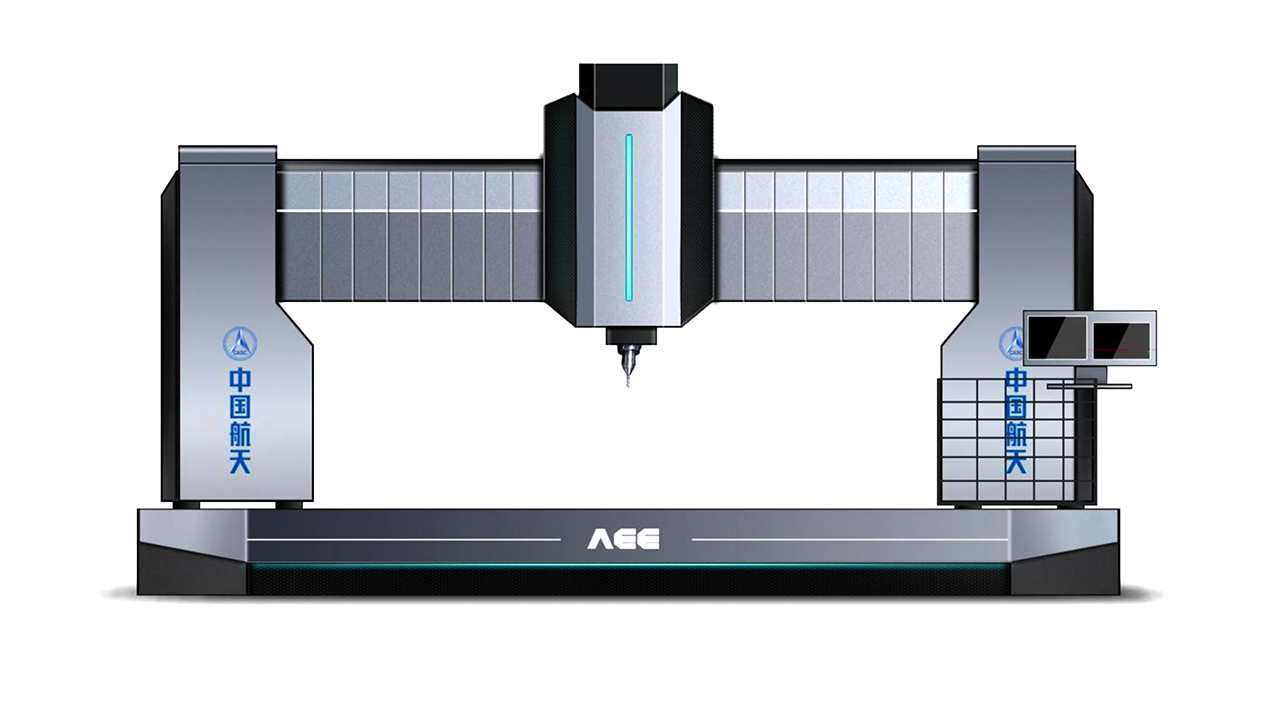

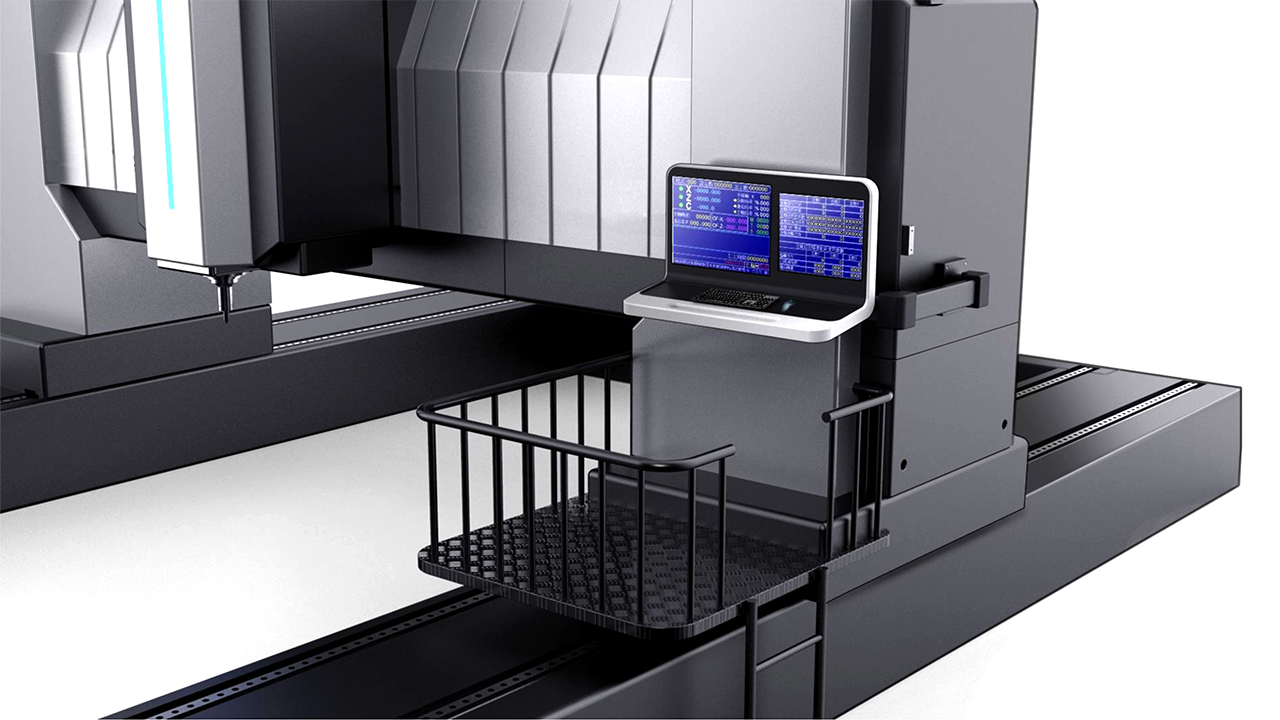

Top Grade has built a new generation of movable gantry friction stir welding equipment for aerospace equipment. Through thinking and trend analysis of future equipment, starting from the product style and details, grasping PI characteristics, determining the serialized product color matching and product details, improving the product grade and professional sense, looking forward in the future, giving people a strong impact sense and product identification.

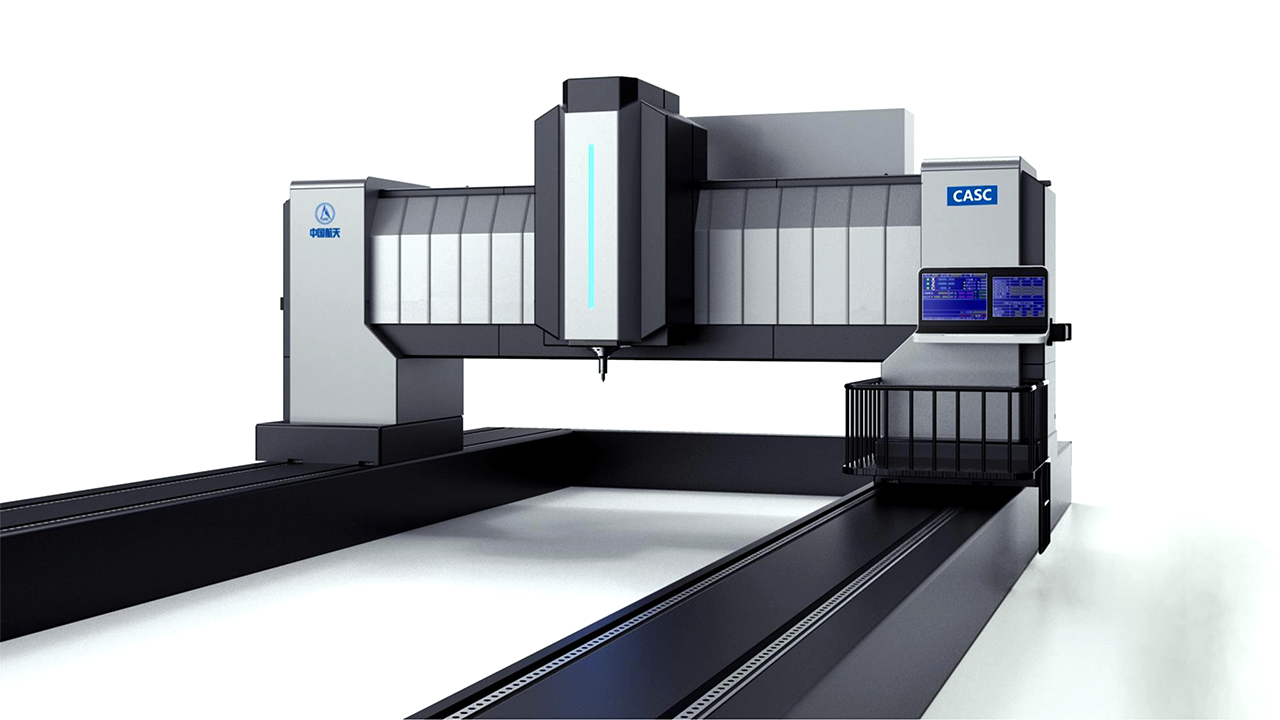

Moving gantry equipment is equipped with different welding spindles and transmission systems according to different working conditions for products developed by splicing large-size flat products. The moving gantry friction stir welding equipment can realize stable and reliable welding of conventional one-dimensional and two-dimensional curve welds, and the moving gantry equipment is equipped with parallel head spindle or AC double swing head and five-axis control system to realize three-dimensional curve welding. Currently used in rail vehicles, aerospace and other light alloy plate products processing.

Heavy-duty Longmen friction stir welding equipment is packaged and sent to Hunan Zhuzhou Liancheng Group-a high-quality supplier of CRRC Zhuzhou Electric Locomotive Co., Ltd. The equipment is mainly used for the welding of traction beams and bolsters of rail transit, helping customers to solve the problems of large welding deformation, low performance and multi-layer multi-pass welding in the traditional melting welding of medium and heavy plate aluminum alloy, effectively improving the welding quality and welding efficiency.

The smooth development and delivery of heavy-duty gantry friction stir welding equipment has further expanded the popularity and influence of equipment companies in the friction stir welding market in the rail transit industry, and is a strong confirmation of aerospace quality in China's manufacturing. With the implementation of development plans such as "Made in China 2025", the equipment company will further improve the level of intelligent equipment and production efficiency, continuously strengthen technological innovation, attach importance to technical reserves, quickly and efficiently provide the best solutions for welding manufacturing, and provide customers with Medium and high-end equipment system integration and technical services.

The copyright of this work belongs to 苏州上品设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Professional

That's amazing.