This is a project designed in 2013. It took more than 7 months from the beginning of the design to the completion of the mold. The appearance design started in August. The design-communication-modification-communication-modification-communication-is such a cycle. Because it is for German customers, the progress is relatively slow. It is almost more than two months to determine the appearance. But the final result is still good, successfully got a large order, so far (end of 2018) is still shipping; at the same time applied for appearance patents and two utility model patents. As far as design is concerned, it is not the best, but it has really brought a lot of business to the company.

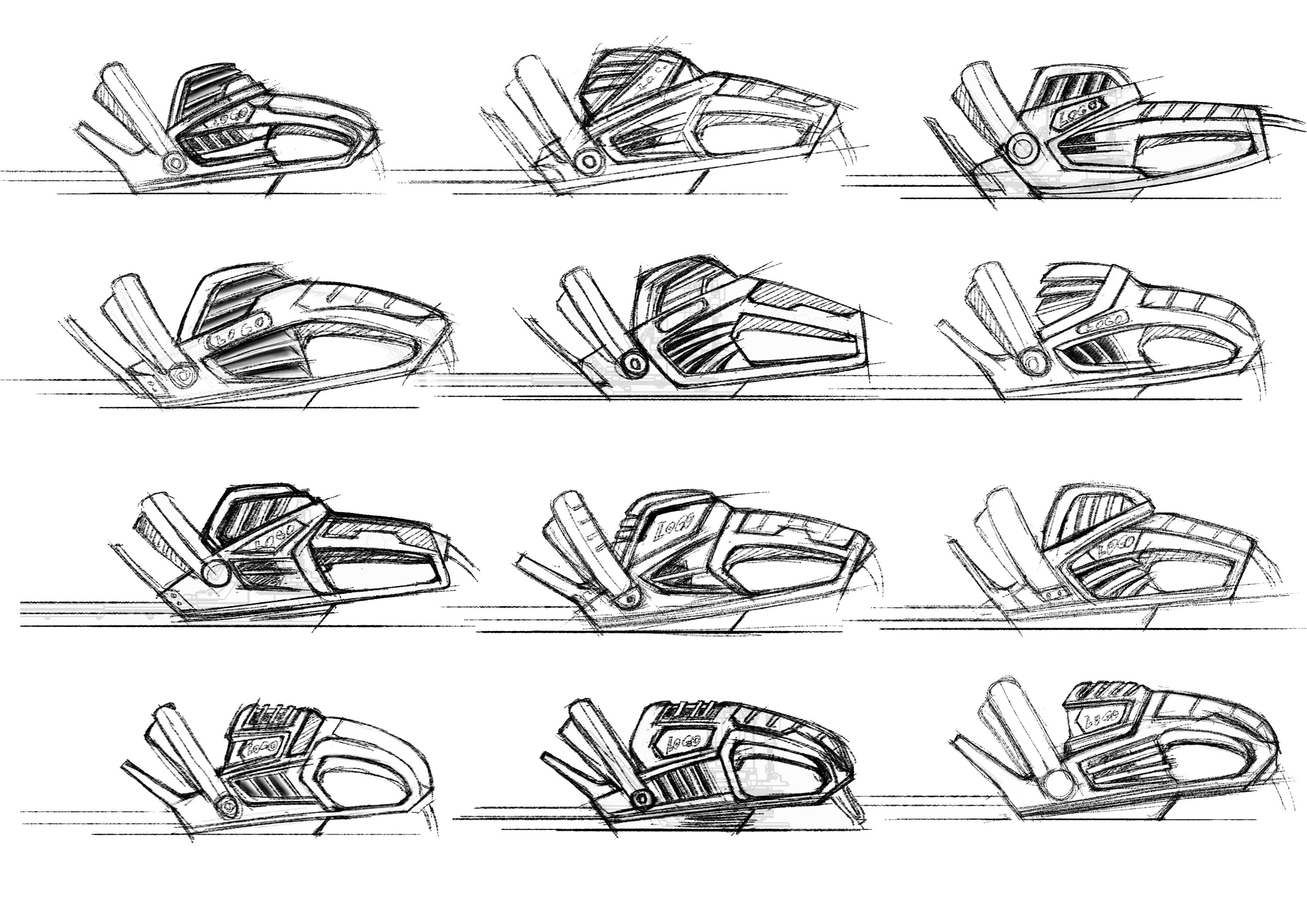

After the sketch stage, on the one hand, the sketch was sent to the customer and other opinions, on the other hand, the two-dimensional drawing was started. The biggest gain in recent years is how to balance the design, and the cost is always the first. So all kinds of changes have been made here, the handle, the black top cover, the protective cover and so on.

In the opinions of some customers and the previous sketches, I found some design elements that were still possible, recombined and made some changes. Now the customers basically agreed. This is to find the right way, and it is much easier to go down.

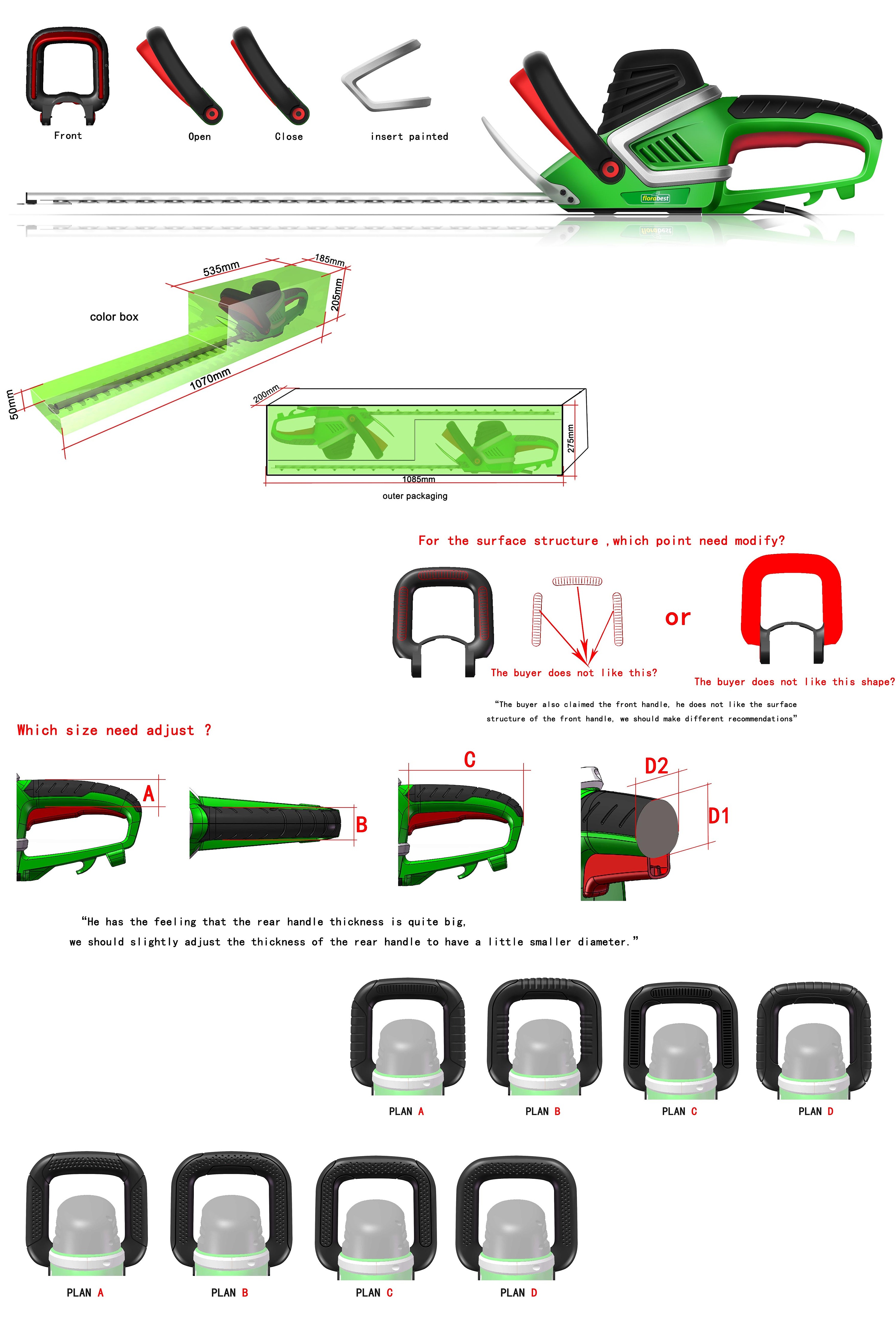

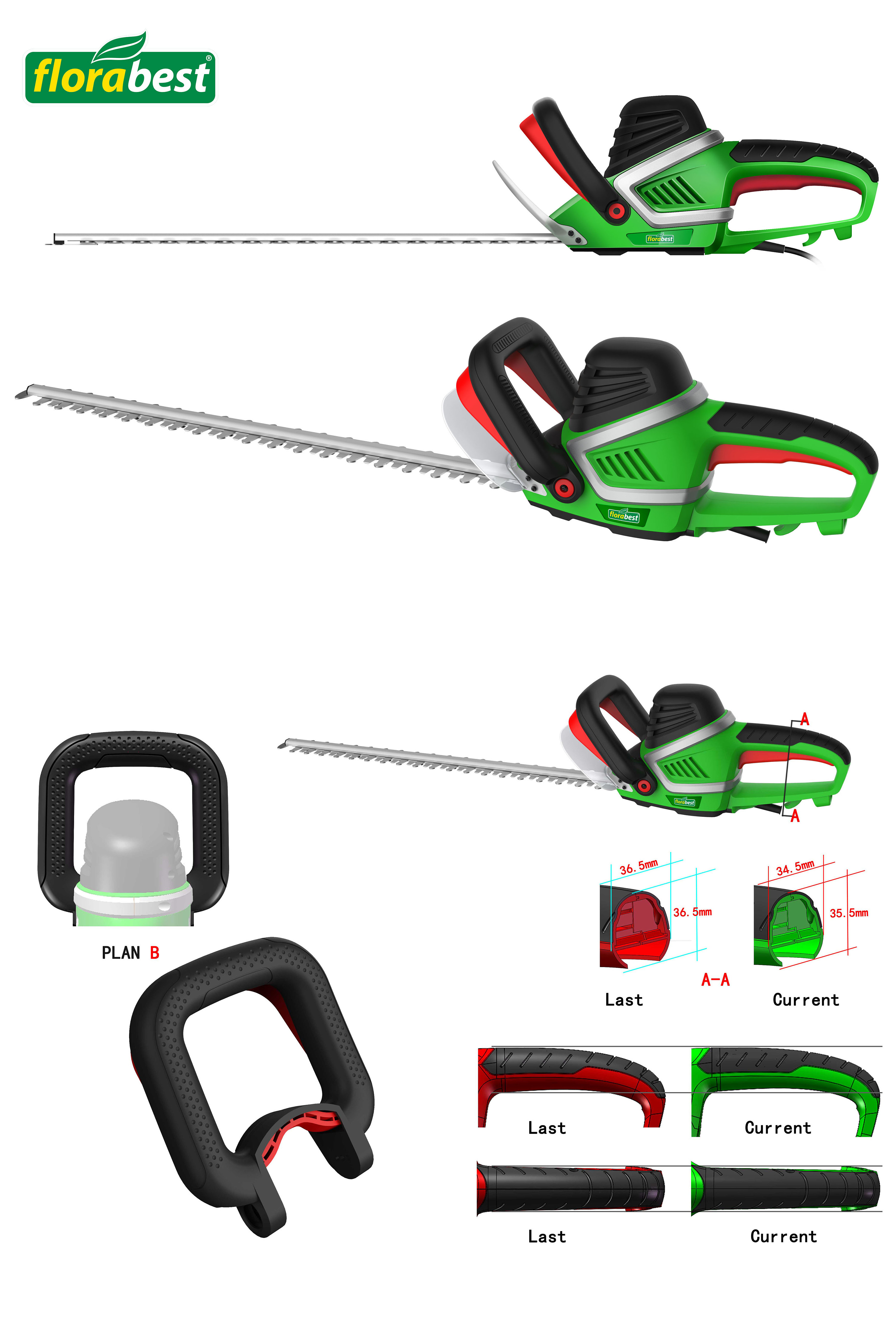

Then I kept communicating with the customer to confirm some details. Due to the tight time, I actually started the production of the three-dimensional model when I was basically confirmed in the previous step. Therefore, there are three-dimensional parts to communicate with the customer about some three-dimensional dimensions, packaging dimensions and other issues. The conversion from plane to three-dimensional has a very good reducibility. It is basically maintained all the time without much change. This is also the basic element of a designer, the imagination and reduction of structure and plane to three-dimensional conversion. The test of ability. The handle is a little square and ugly. This is also a compromise. It only meets the safety requirements. There is not much aesthetic feeling. Being beautiful and smooth will affect the packaging size and packing quantity. However, after I left the company before, when I saw this product online, I modified the premise hand...

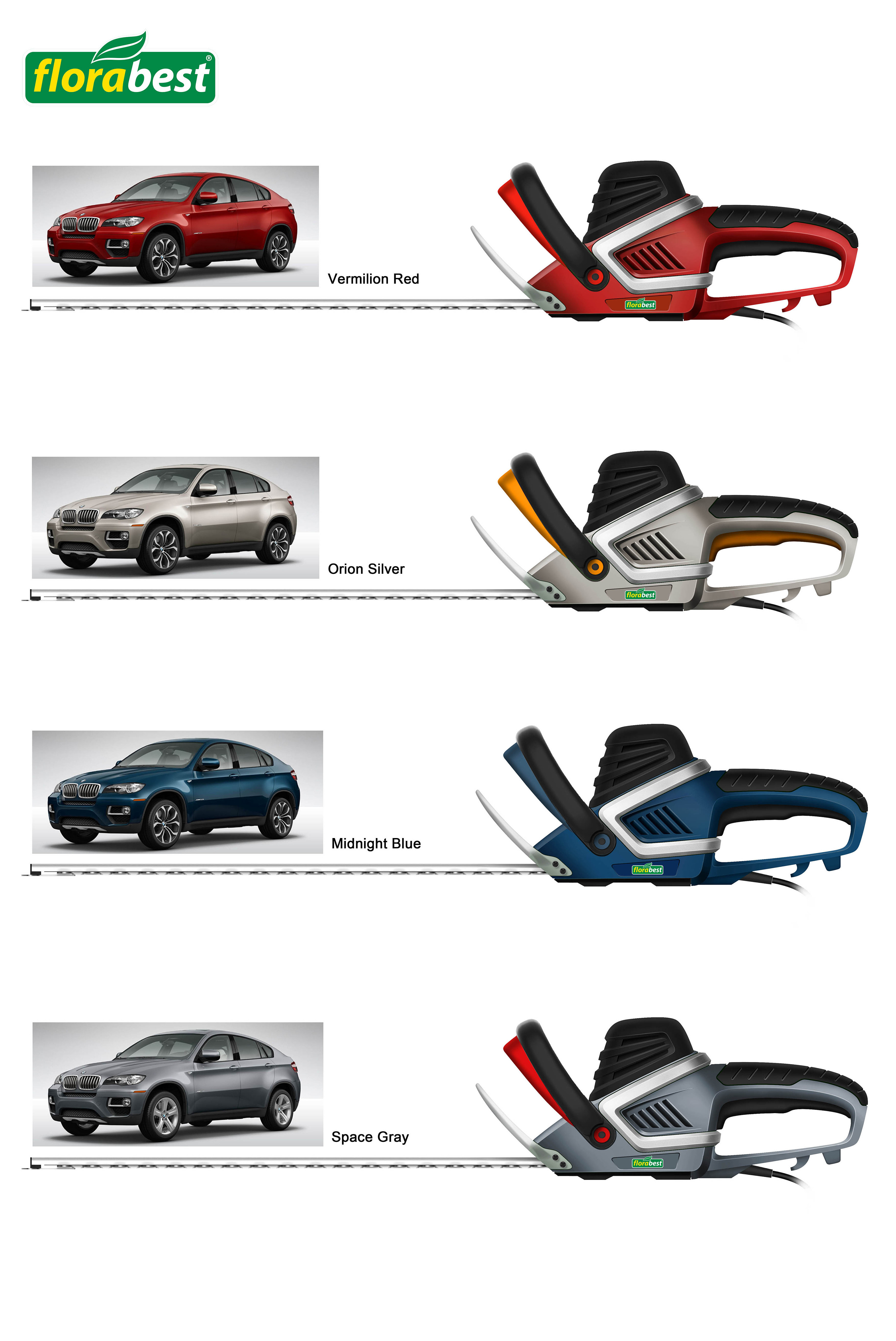

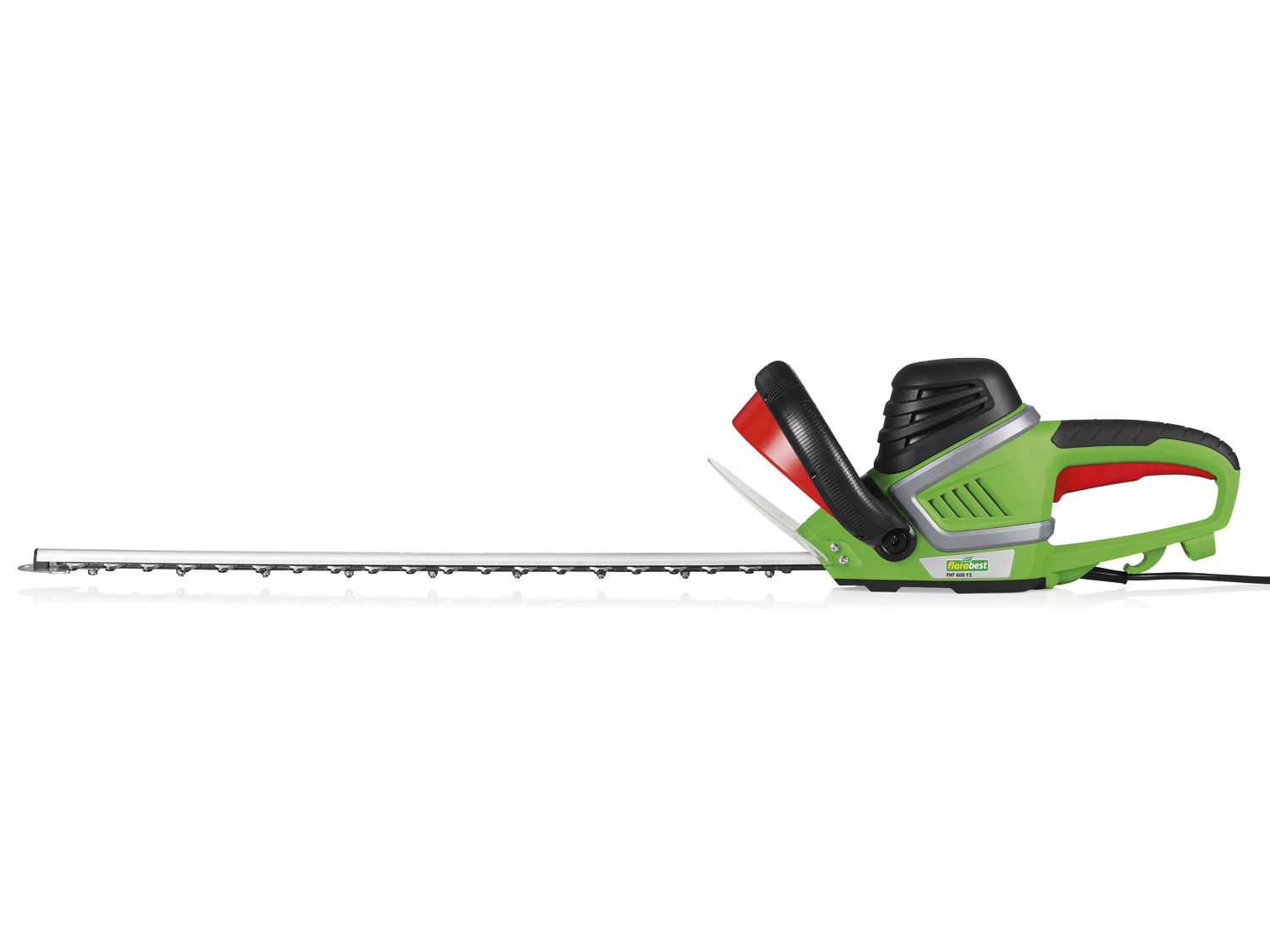

This is the final product. In fact, they have their own brand, that is to say, they have their own color requirements. It is very strange that they asked me to match them with several sets of colors, so they made such a few color schemes.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

SUMEC?

Peer, learned

Brother, are you from the design company

It's a great product. It can get orders from German customers and return so many orders, which is enough to prove how successful it is. Sales volume is the only criterion for the success of an industrial product.

Excuse me, are the sketches in the early stage and the data modeling in the later stage done by one person or by two people separately?

Do you draw an effect diagram directly after the sketch is finalized?

https://www.lidl.de/de/florabest-elektro-heckenschere-fht-600-f3/p284847

This?

Is it popular now that you can lean directly on your body, which is convenient for long-term homework?

Foreign brand

Like passing by, support