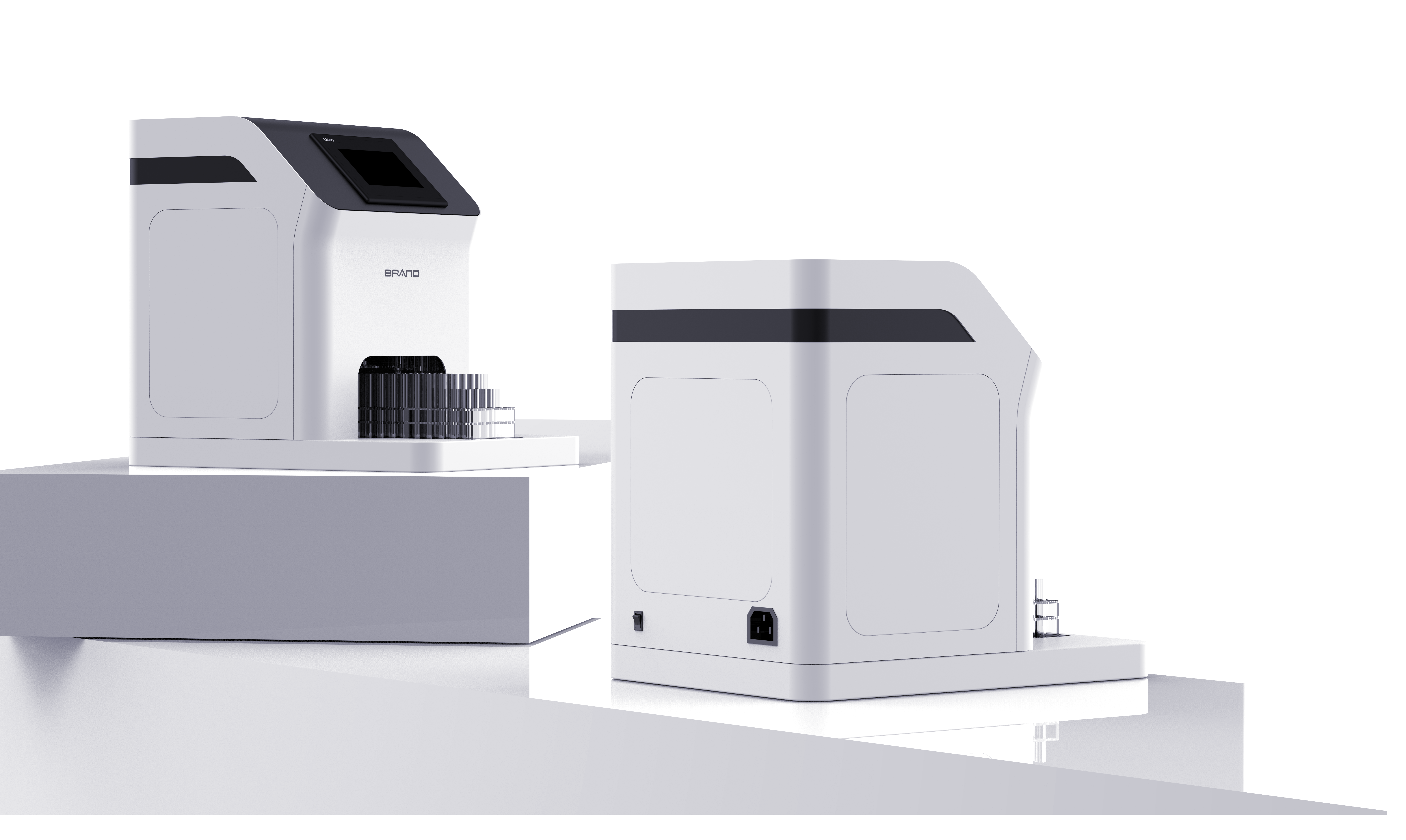

According to the design requirements of the medical sealing machine, the design revolves around the core elements of "simplicity, white tone, forward edge of the screen area and arc design" to conceive a design scheme that not only meets the requirements of the medical environment but also has a good user experience.

The overall shape is simple and the lines are smooth: the combination of straight lines and soft curves is used to remove redundant decorative elements and ensure the simplicity and unity of the overall shape. The straight part can be used for the main frame of the fuselage to show the stability and professionalism of medical equipment, while the curve is used for detail processing, such as corner transition, to increase affinity.

Pure white: Choose high-purity white as the main color, not only in line with the medical environment for clean, sterile high requirements, but also to create a quiet, comfortable atmosphere. White is also easy to integrate with various medical equipment and environments without being obtrusive. The edge of the screen area is slightly forward and cambered design, forward design: the screen area is designed to be slightly forward angle, which not only facilitates users to clearly view the screen information at different angles, but also naturally guides the line of sight and improves the comfort during operation. The angle of the forward tilt should be ergonomically tested to ensure the best viewing angle.

Arc surface design: The edge of the screen and the surrounding area adopt arc surface design, which can effectively reduce the visual and physical discomfort caused by sharp corners. The cambered surface can also reflect or disperse light to a certain extent, reduce the reflection of the screen and improve readability. At the same time, this design also increases the overall aesthetic and tactile comfort of the product.

The copyright of this work belongs to Fun. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Do you need shell proofing and small batch processing? 3D printing, CNC machining, silicone overmolding and rapid tooling can all be done

this is very good

for the milk tea shop

Excellent