This article is mainly to make a simple design process for sheet metal products. About 4-5 months before and after the project. Finally, a satisfactory answer was delivered to the customer. At the same time, I hope to help designers.

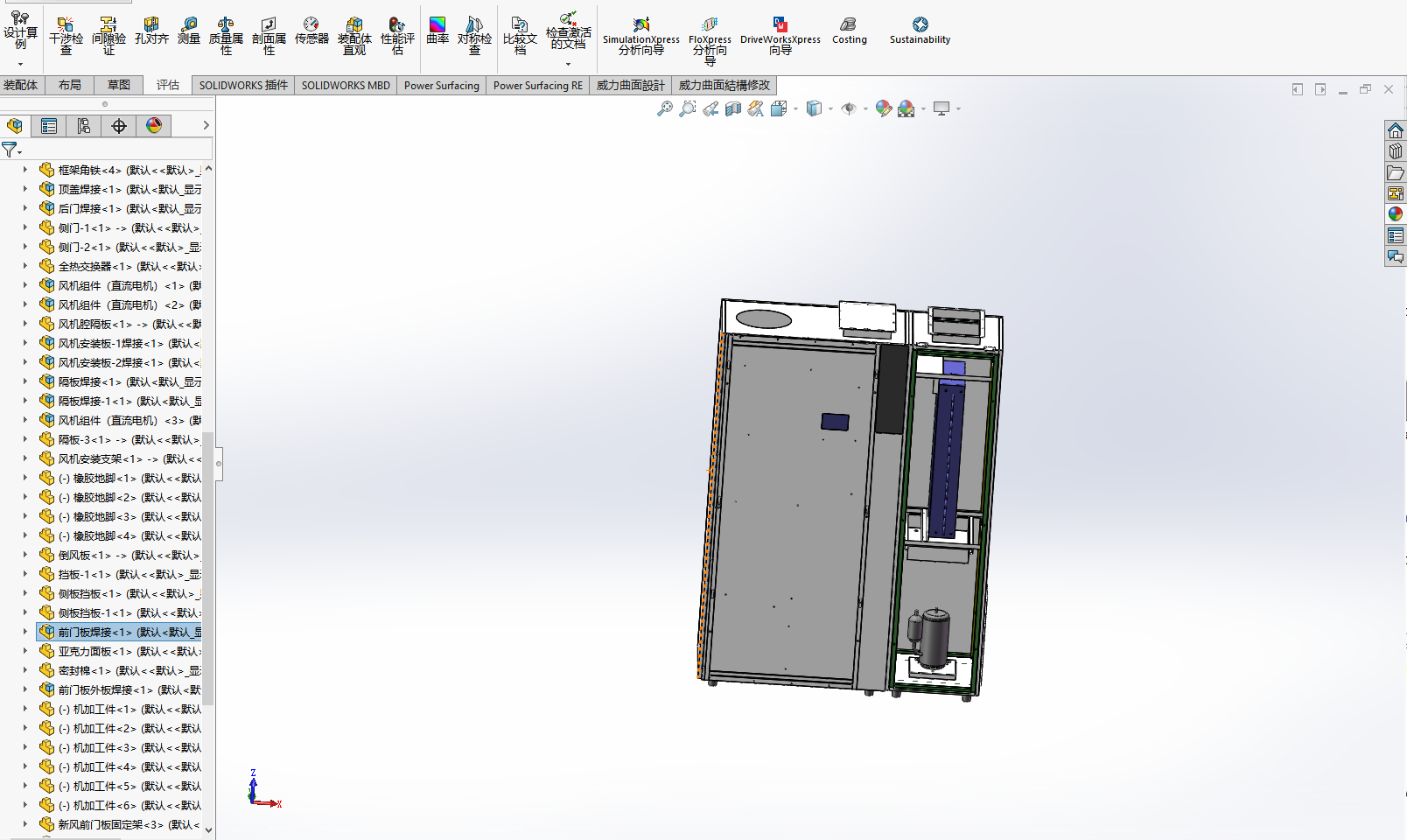

Send a simple process of product design and development. There are too many intermediate processes. Simplify it and show it through this form. The purpose of this project is to make a large dehumidifier for swimming pools, warehouses, etc. High power and high throughput. This is a 3D diagram of Scheme 1. It is also the final plan. The customer chose this model as production.

Scheme 1 Other perspectives, of course, the final production and renderings have some adjustments.

The effect diagram of scheme 2 is also a simple sheet metal design, and my personal feeling is also very capable and overall. It is a mature scheme design.

This treats the frequently opened door-to-door, the lower door is beveled, and the corporate color of the customer's products is silk-printed. It is convenient to reach out from the bottom and knock on the door. This design is very clever. And it hides complicated things.

This is a two-dimensional plan for interns. It's a long story. There are too many aspects that need to be improved. The overall plan is broken. Moreover, a 3-dimensional proposal can be made in 2 weeks. Interns finally get a 2-dimensional proposal. This kind of proposal is very abrupt and the clearance rate is too low. Therefore, I advise you to make adequate preparations when designing proposals. The customer will know the workload at a glance, because he is a small expert in this field. It is not the requirement of two-dimensional and three-dimensional, but the difference of intention. Two-dimensional proposals are also possible. I have even made sketches. As long as I design the main points of the design, there is no problem at all. What I fear most is that there is no design and no workload.

After the customer selected the plan, it was appropriately modified. Due to the low output, the factory does not recommend too much R angle. So many places have made sheet metal bends.

Structural design, copy the number of parts, and assemble into the machine. There are probably more than 100 large and small parts. The process should be marked on the drawing for each screw position. In this way, the factory will not be confused.

Structural renderings. Internal components, etc.

At the same time, the UI of the control module should also be designed.

To the factory. The factory starts processing, and when the construction period is about to reach, we will consider testing the machine according to the requirements. test performance, etc. This is to come to the sheet metal factory supervisor.

The sheet metal master is bending and making parts.

There are no photos for welding. This is the scene after being pulled out of the spray booth. The black in the middle has been sprayed many times, mainly because the welding has been made into one piece. This is a great challenge to the two colors of sheet metal. Therefore, the sheet metal should be packed in two colors, preferably in two separate parts. This paint color is independent. Of course, the color of small areas can be silk-screen printing. There is no need to consider this aspect of the process.

Assembly of internal components. Two people, it is still a bit difficult to install this large machine. Certainly not faster than workers. Ha ha

The test is complete. No problem. Wrap the film.

The head of the workshop guides the female workers to work.

After the film is wound, pack the box. Prepare to send logistics to customers. There are also after-sales, operation guidance and other work.

The copyright of this work belongs to 北京钣金. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Hello, does your sheet metal factory have an address?

I feel that this customer's screen is definitely dead and a little restricted. The small screen with such a large blank area feels a little low-end. (Personal feeling)

This young man does not speak martial arts.

https://www.zcool.com.cn/work/ZMjU4NzY1NDA=.html

From design to processing, it is very detailed! Hard work, I hope this realization of the design of the manufacturing process can be more!

Do you need to do structure for ID now?

how much dehumidification is and how much air volume is, can you talk about it?

I would like to ask the author

How can Solidworks modeling improve its surface modeling ability more efficiently

There don't seem to be many internal components.