Microwave heating has the characteristics of rapid heating, selective heating, easy control, and uniform heating. Microwave technology was used to heat and dry tobacco leaves. The heating area greatly increased. The moisture uniformity of the dried tobacco leaves was much better than that of the tobacco leaves processed by the existing technology, which effectively solved the different moisture content of the tobacco leaves before drying. The moisture content of the dried tobacco leaves is not uniform due to the different positions of the tobacco leaves. At the same time, the microwave heating and drying process is a uniform process. The tobacco leaves will not be conducive to the processing and use of the leaves by cigarette enterprises because of curling.

Microwave drying is easy to control and adjust, and the reaction time of the drying process is faster than the original method-the use of microwave to heat the re-cured tobacco leaves is conducive to killing the eggs of tobacco worms, effectively preventing the tobacco from harming the tobacco leaves by the insect source carried by the tobacco itself during the storage process, thus greatly improving the quality of the tobacco leaves. Therefore, microwave tobacco redrying will become a highly efficient, energy-saving and economical means of tobacco redrying.

Microwave heating will produce an alternating applied electric field. The molecules in the material are ionized and polarized under the action of the electric field, which has positive and negative characteristics, and high-frequency oscillation occurs with the alternating change of the electric field, thus generating hot stars. Compared with conventional heating, limb wave heating is directly heated by energy dissipation inside the material, which can overcome the cold center of the material without heat conduction from the outside to the inside, and realize rapid heating!. At the same time, the microwave heating process directly transfers the energy required for the chemical reaction to the molecules or atoms of the reaction, and this in-situ energy conversion method makes the chemical reaction and diffusion process fast.

The dynamic direction of microwave re-curing tobacco leaves is shown in Figure 1(5). The temperature gradient from the outer layer of tobacco leaves to the inner layer of heat conduction direction is the same as the direction of steam migration. Microwave energy penetrates into the tobacco leaf and is absorbed, and its energy is instantaneously converted into heat energy to raise the temperature of the whole tobacco leaf forest (including the temperature of the inner tobacco leaf and its moisture content). At this time, the water vapor pressure of the inner layer suddenly rises to drive the water vapor to the surface of the tobacco leaf, and the dry layer first appears in the inner layer of the tobacco leaf and expands to the outer layer. Microwave redrying of tobacco leaves is the overall heating process has two major advantages: the overall temperature difference of tobacco leaves is small and the heating time of tobacco leaves is short, avoiding the problem of hard shell on the surface of tobacco leaves.

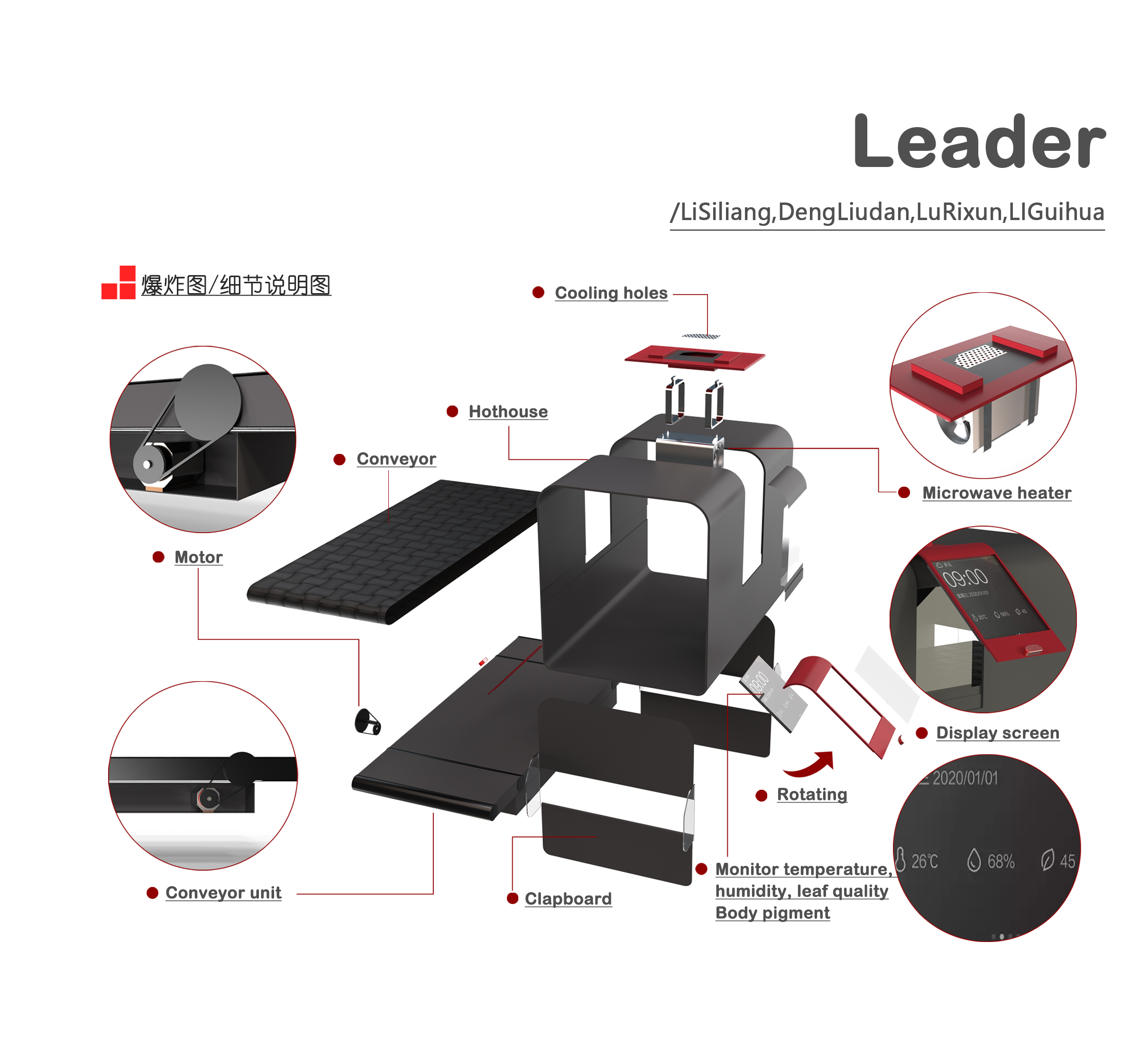

The intelligent monitoring and control system can monitor the temperature, humidity and leaf plastid pigment, and can adjust the temperature and humidity intelligently.

The change of plastid pigment is one of the most intuitive changes in the process of tobacco curing, and it is also an important basis for rapid real-time judgment of the quality of tobacco leaves in the curing room and the implementation of baking operations. By collecting the near infrared spectra of tobacco leaves with objectivity and repeatability, the change trend of plastid pigment with the baking process can be preformed.

Fuzzy control is a linguistic intelligent control method that imitates human reasoning and decision-making to describe the control rules by conditional statements. In practical application, it is widely used because it does not need to establish accurate mathematical model, simple control and easy design. Its basic composition is shown in Figure 1.

The control method first sends the digital signal collected by the sensor into the reasoning machine after fuzzification, and then obtains the drive control amount by defuzzification operation, and finally realizes the intelligent control of temperature and humidity through the hardware controller operation execution element. The inference engine part is mainly composed of fuzzy control parameters and fuzzy control rules, in which the control rules are generally empirical logic formed by experts with rich theory and field operation experience, usually in the form of "I condition, ther result to express fuzzification is a method to convert accurate input digital quantity into fuzzy quantity, generally, the exact quantity can be converted into the fuzzy subset or fuzzy single point set on the standard domain to realize the opposite of fuzzy solution and fuzzy, that is, the exact digitization of fuzzy quantity can be realized by the maximum membership method and the center of gravity method. The output data after the solution can be the actuator, such as the opening of the heater, the rotation angle of the motor, etc, finally, it is realized by PLC's analog output, PIWM pulse width modulation, pulse quantity and direction control.

This product is mainly aimed at the simple treatment of tobacco leaves after picking, to avoid the accumulation of mold leaves, and at the same time, the packaging and transportation process after drying can also effectively ensure the integrity of tobacco leaves and the quality of tobacco leaves, and reduce economic losses.

The copyright of this work belongs to 李思良. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Not bad

The tobacco companies will use it.