| 2021IF Design Award

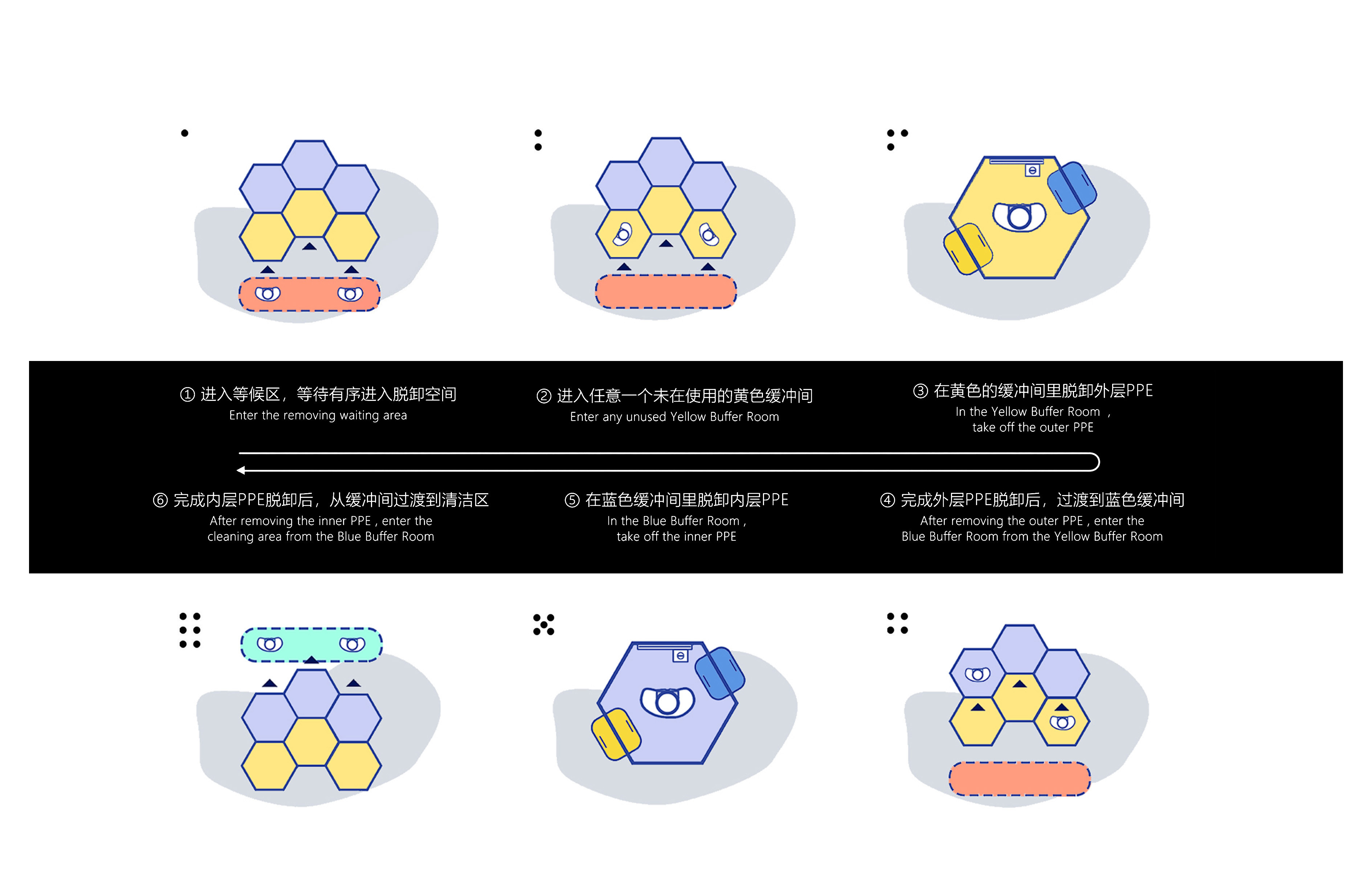

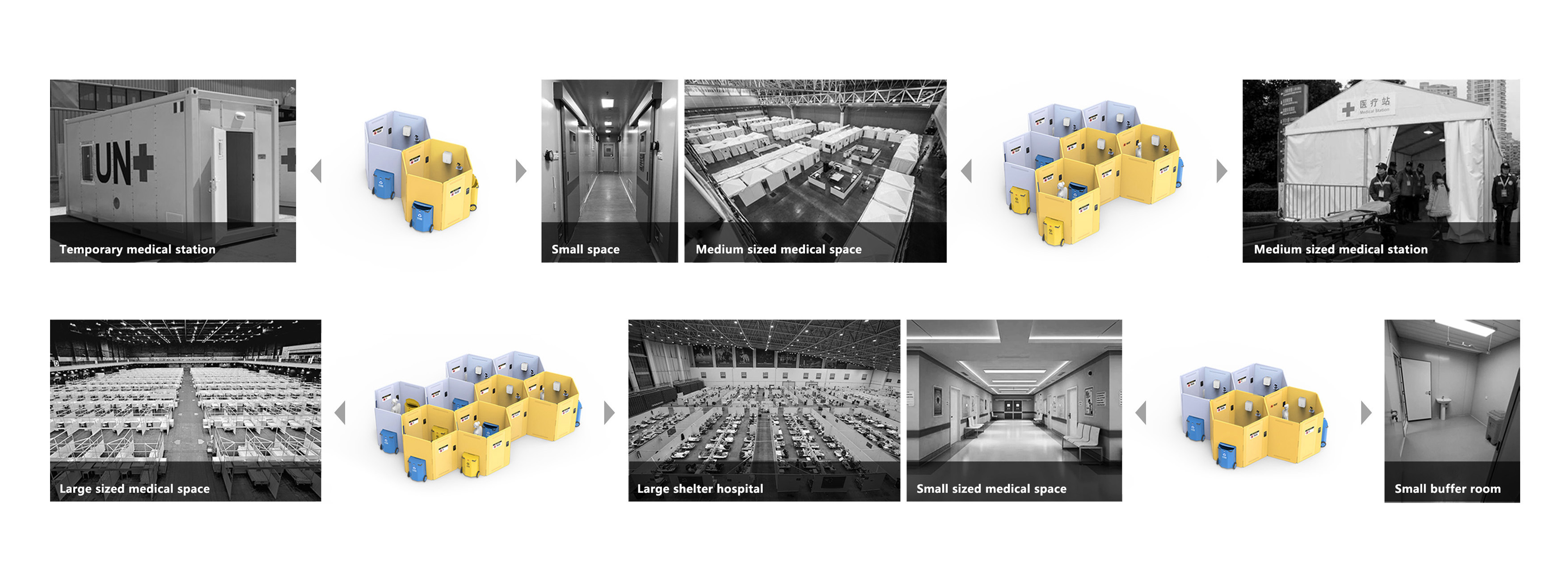

Since the global outbreak of the novel coronavirus (2019-nCoV) at the end of 19 years, many health care workers have been infected with the virus. An important reason for this group of infections is the irregularity of personal protective equipment (Personal Protective Equipment, PPE). PPE unloading auxiliary system can help medical personnel to safely unload PPE. The system space is built by modular partitions. Partitions of different colors are used to divide spaces with different pollution levels. The outer PPE is removed in the yellow buffer room and the inner PPE is removed in the blue one. Users only need to pass through the yellow and blue buffer rooms in turn to complete the unloading and transition from the contaminated area to the clean area at the same time. There is a voice prompt in each buffer room, which takes hand hygiene as the interaction point to provide users with complete operation tips and help users reduce the error rate of unloading operations. The whole unloading system adopts zero contact interaction mode, which effectively reduces the infection rate of medical care and makes the unloading process simpler, more efficient and easier.

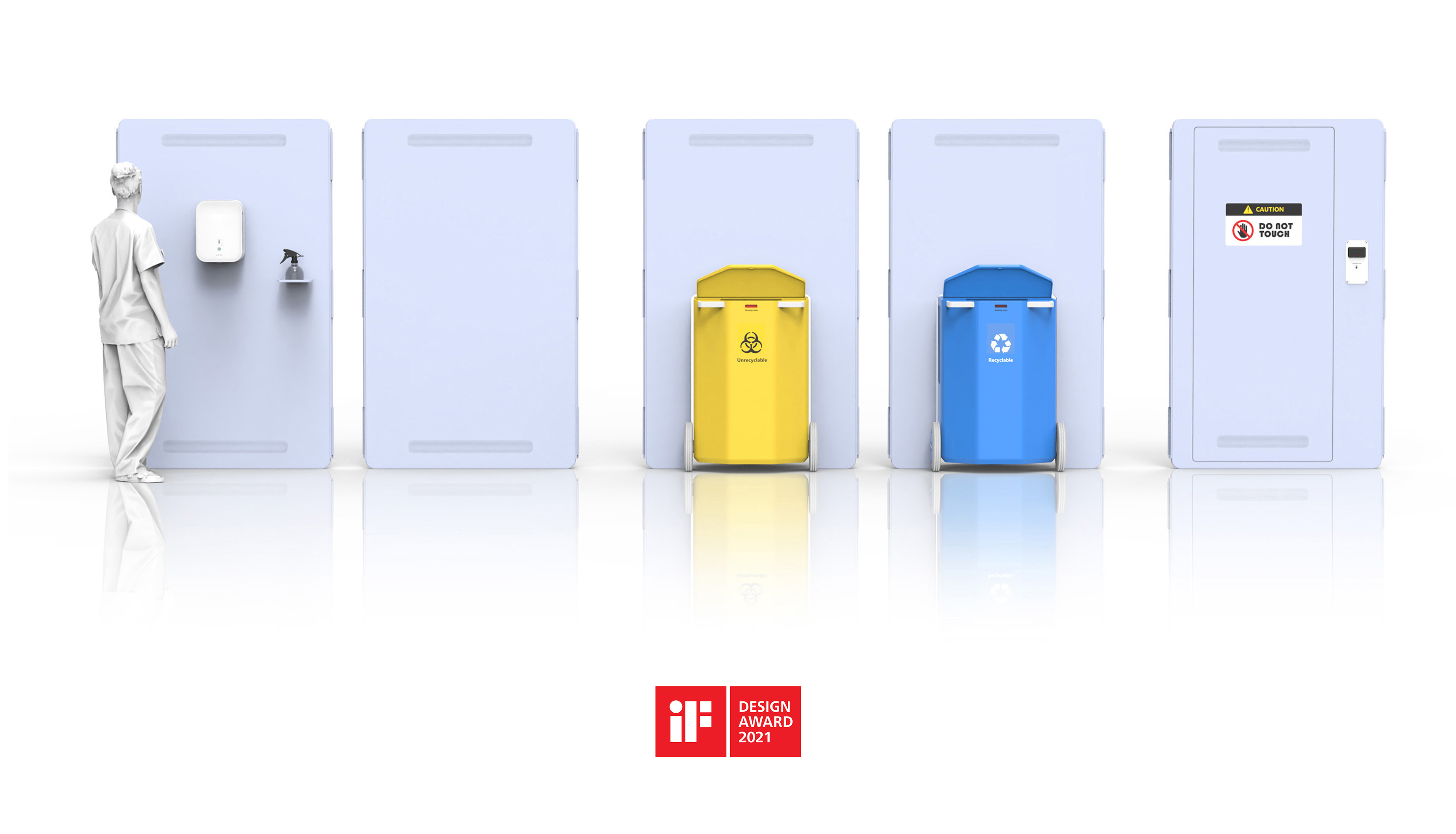

Since the worldwide outbreak of COVID-19, many front-line health workers have been infected. One of the most important reasons of their infection is the non-standard operation of removing personal protective equipment (PPE). To solve this problem, we design a PPE removal assistance system. It provide the complete prompt information on how to remove the PPE correctly, so as to reduce the infection rates in the removing process. In addition, this system separates and plans the space. The entire system adopts a contactless interaction method to avoid cross-infection,and make the removing process simpler and easier.

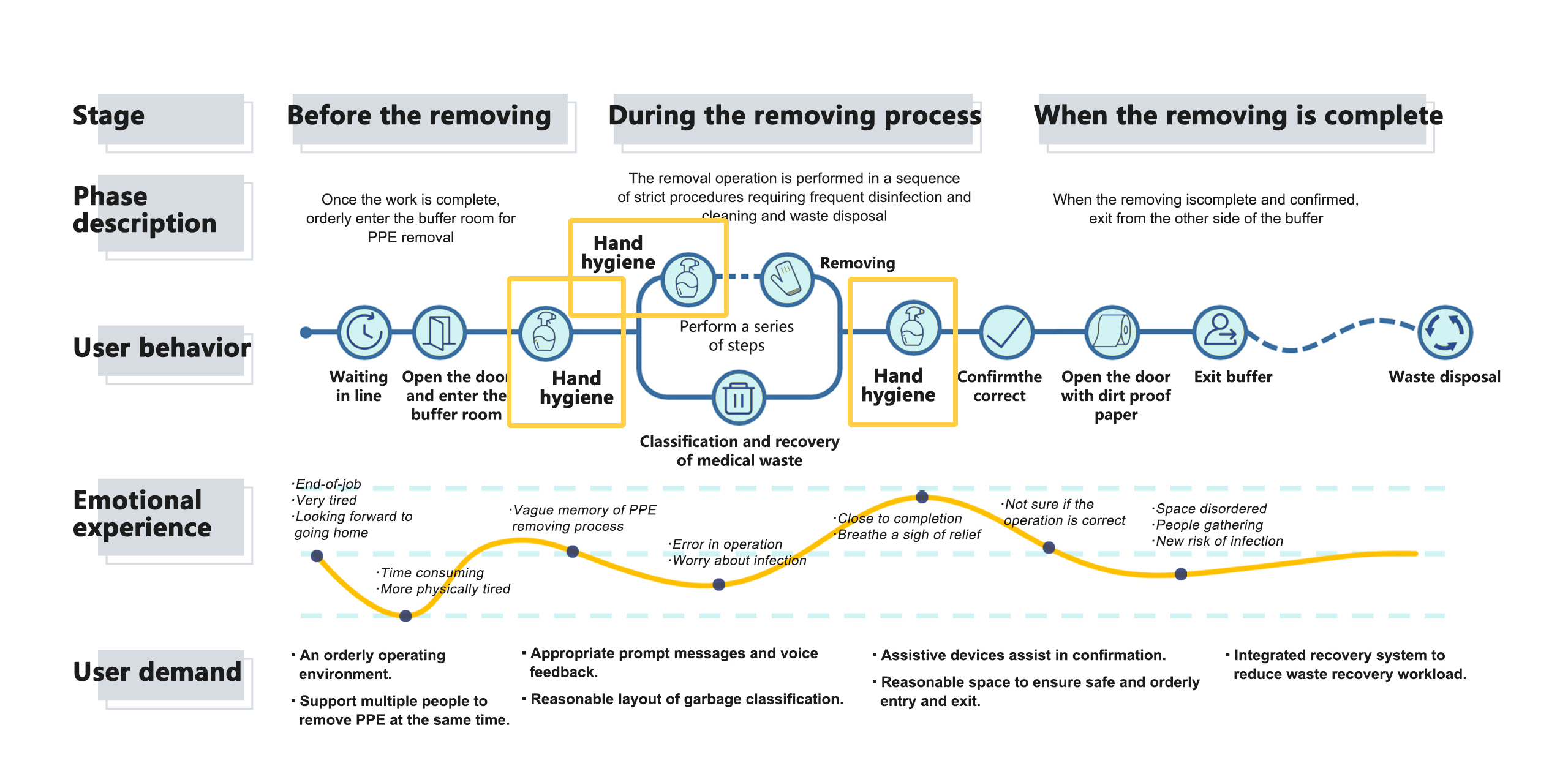

The survey found that due to unskilled unloading, work fatigue, unclear vision caused by fogging of goggles and other reasons, some medical staff will make operational errors when unloading PPE, which can easily lead to infection.

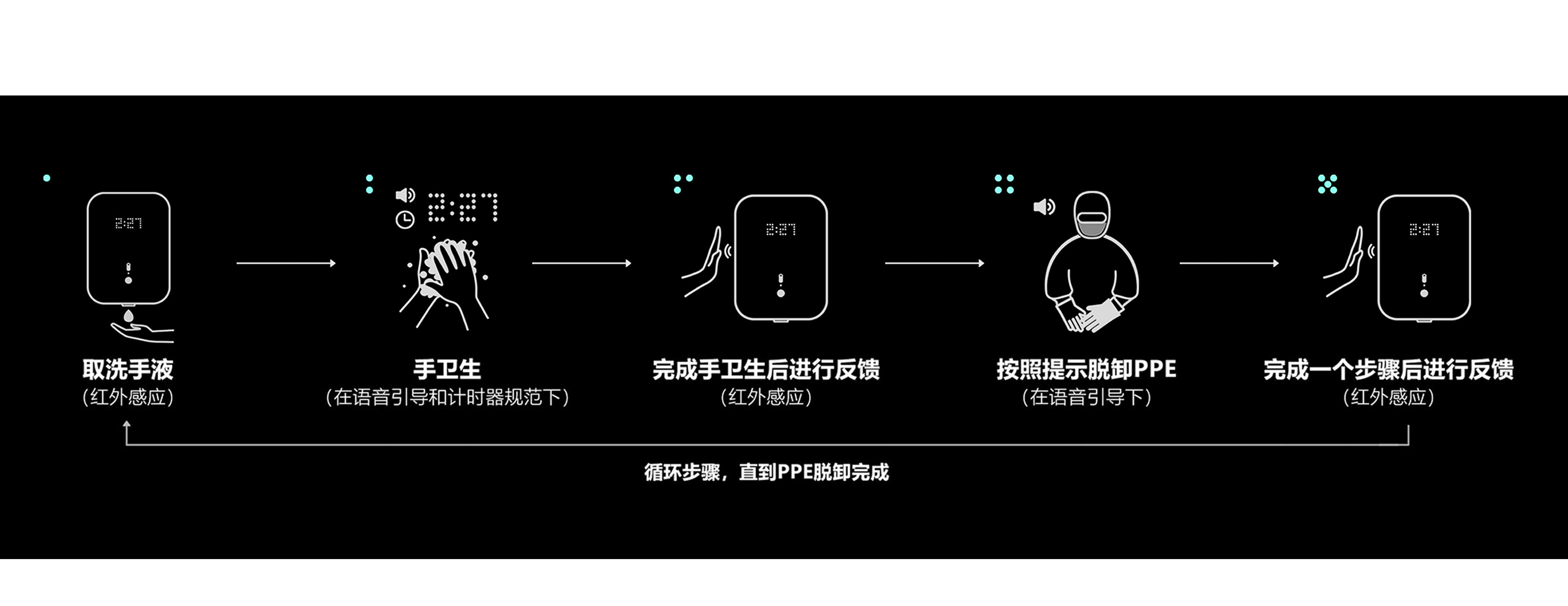

Hand hygiene is an important link in PPE unloading process. Hand hygiene is required for each step of unloading operation. Hand hygiene runs through the whole unloading process. Therefore, the design of PPE unloading voice prompt takes hand hygiene as the starting point, providing users with complete unloading voice guidance and helping to standardize unloading.

The PPE Disassembly Voice Prompter is mainly pearl white and light gray in appearance, and the shell is simple in shape and smooth in surface. Its purpose is to reduce the adhesion rate of viruses on the product and to make it more convenient to disinfect and sterilize the product.

In order to avoid cross-infection during the use of the product, the PPE release voice prompt adopts the interactive mode of infrared induction, and assists the release through the way of full-process voice prompt, thus ensuring safety and making the release process easier and more efficient.

There is an infrared sensing area on the side and bottom of the reminder, and the user interacts with the reminder in a contactless manner.

As above, the specific use steps of the PPE release voice prompt are: after entering the buffer room, wake up the device through the infrared induction at the bottom and draw the hand sanitizer, the prompt will tell the user the operation rules of hand hygiene through voice, and restrict the standard hand hygiene time through countdown; After the hand hygiene is completed according to the prompt, the prompt will give feedback to the prompt through the infrared induction on the side, and the prompt will give the requirements, and provide voice guidance; After completing the instructions of the disassembly step, it is fed back to the reminder through infrared induction, and the hand hygiene is entered again. The whole disassembly process is completed through the mode of (hand hygiene-disassembly-hand hygiene-disassembly) cycle. With the help of PPE release voice prompter, users do not have to worry about forgetting or remembering the wrong steps and making mistakes, thus reducing the psychological burden and increasing the standardization and safety of the release process.

The unloading system divides spaces with different pollution levels through partitions of different colors. The outer PPE is removed in the yellow buffer room and the inner PPE is removed in the blue buffer room. Users can complete the unloading only by passing through the yellow and blue buffer rooms in turn, and at the same time complete the transition from the polluted area to the clean area.

The specific use process of the dump system is as above.

The design of modular partition makes the construction, disassembly and transportation of PPE disassembly system more convenient. At the same time, users are free to build a release system suitable for different space sizes.

The copyright of this work belongs to 努力努力努力. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

GOODJOB

How does infrared sensing confirm whether it is disinfected or not

This design is like a honeycomb

iF award, creative points do exist, great!

Good job!

I didn't fully understand it. Is it used in a shelter hospital???