Our original, individual (organization)) do not use the order to profit

The copyright of this work belongs to 觅奇设计18665416020. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

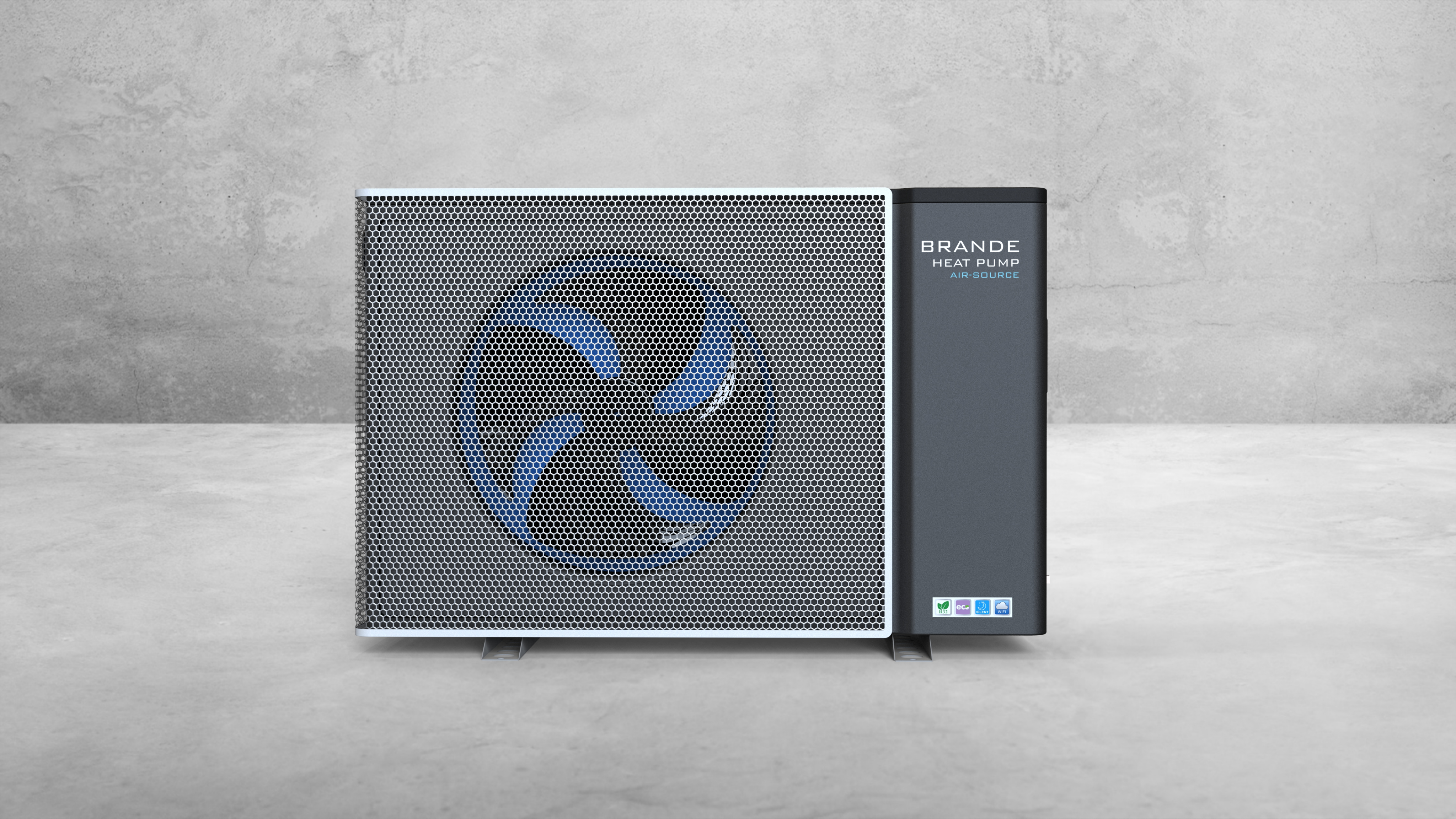

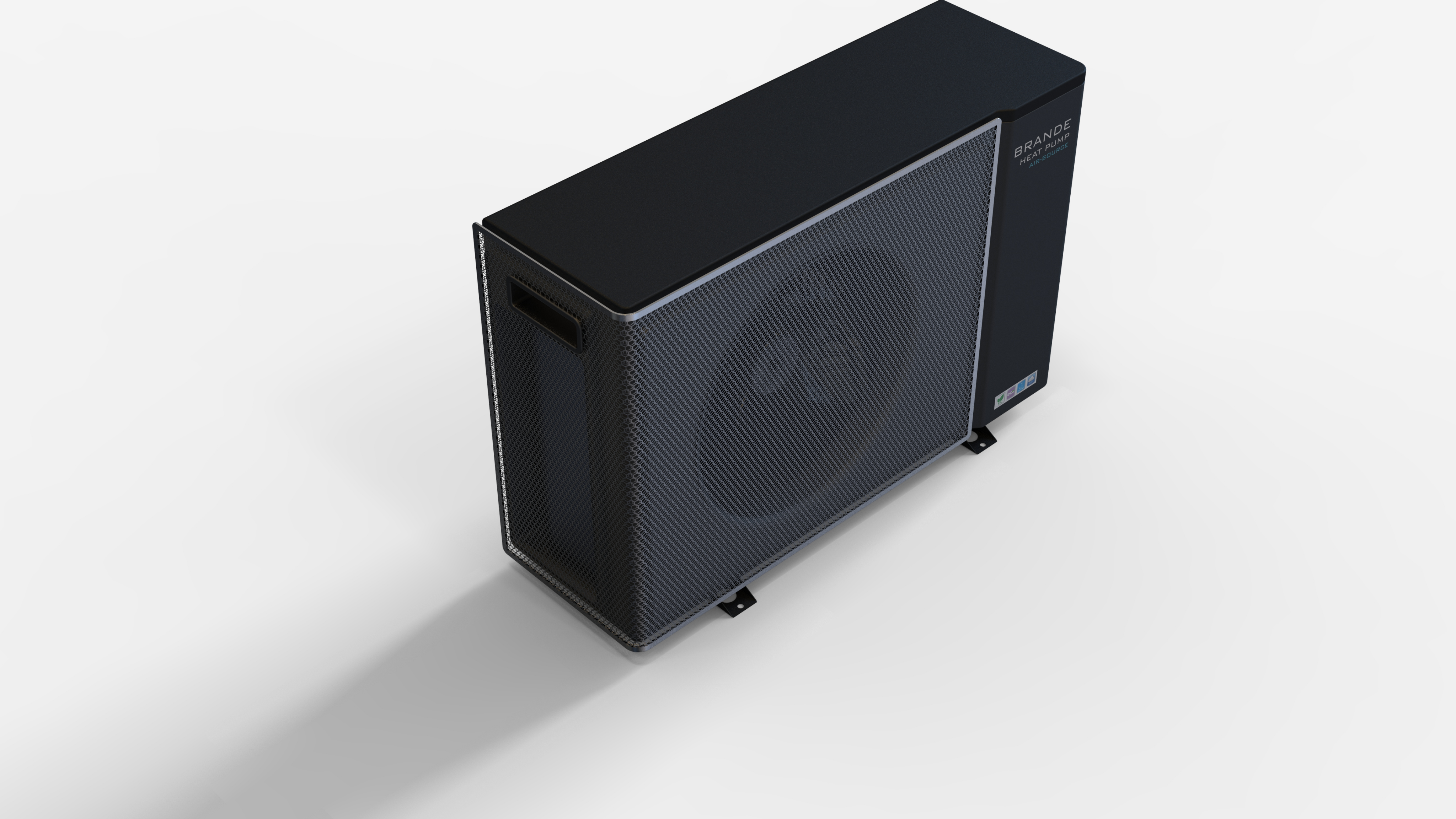

The idea of replacing the grille with a perforated screen was used in 20 years. I have communicated with the research and development part of the air conditioner and made a hand board. There are two reasons why it did not push forward in the end,

1. In terms of safety regulations, if you want to pass the anti-touch test finger, the aperture of the punching mesh plate should be 8mm, so that the air intake of the external machine will be lost and the energy efficiency will be affected.

2. In terms of cost, the punching mesh plate covered with the entire external machine surface maintains a certain flatness. The reasonable thickness is 0.8mm, which is more than twice the cost of the injection molding external machine grille. The injection molding grille can also reduce the air volume loss through curved surface simulation. Unless the product's requirements are particularly sufficient, ordinary household and commercial external machines cannot use this scheme. Only the beautiful COLMO central air conditioner has a similar mass production scheme.

Add chicken legs to the design

I learned new knowledge again.

Good professional equipment

not bad

For what use