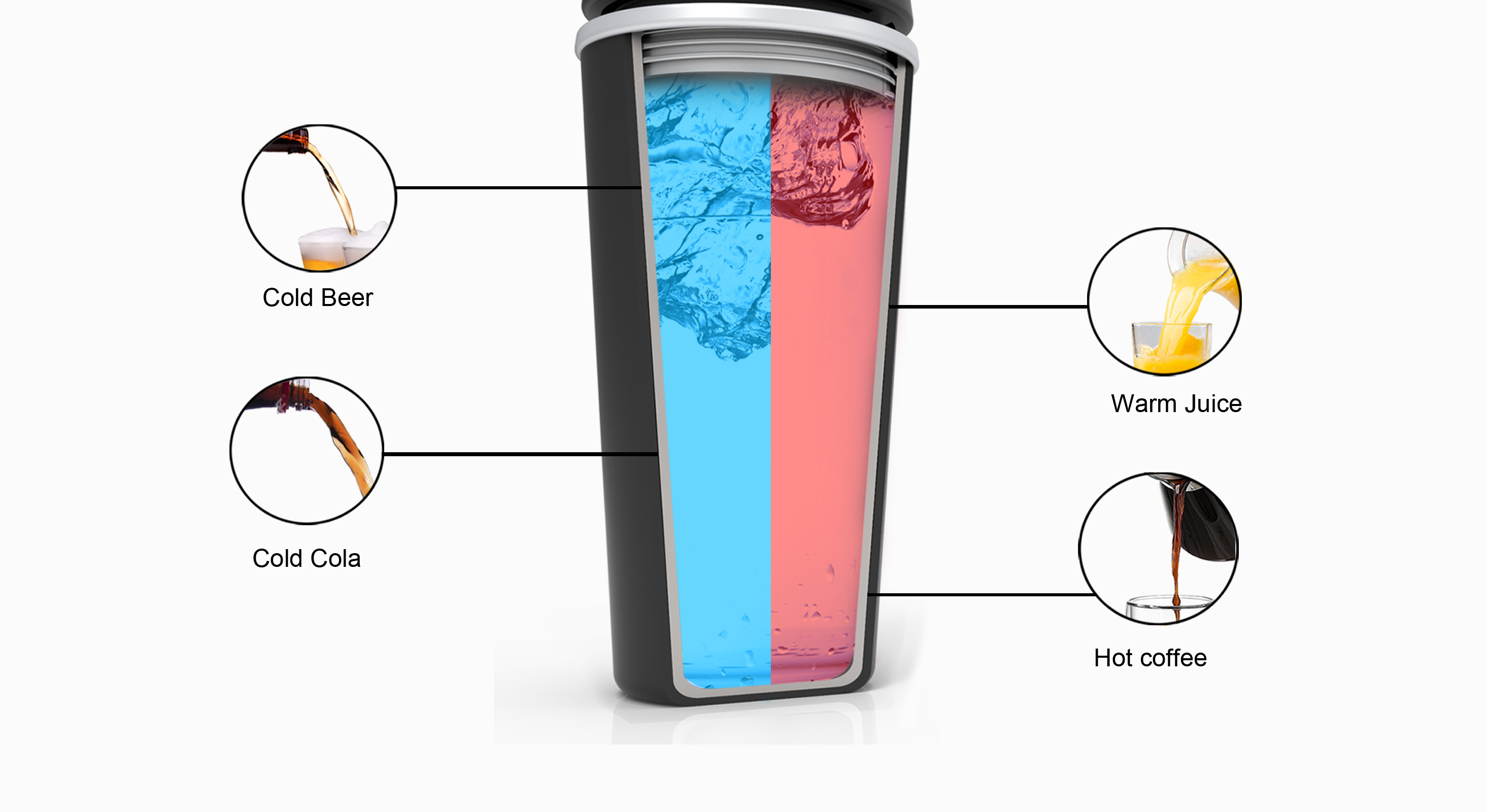

We have imagined for many years, and we have also been interviewed by CCTV in China for inventing the world's first rapidly frozen product. At this time, we found that too many designers lacked understanding of semiconductor refrigeration chips, thus failing to make a qualified refrigeration cup. Therefore, we will make a portable cup suitable for everyone around us, which can quickly cool down or heat the cup for you in driving, home, office and outdoor, camping and RV life, and provide you with more intimate drinking water, coffee, juice, beer and so on.

In 2013, we designed a quick freezer interviewed by cctv and became the fastest beverage cooling machine in the world. It takes less than 5 seconds to cool down at 37 ℃ to 16 ℃

USB power supply mode: cooling 37-5 ℃ takes 10 minutes (10w)

It takes 5 minutes to heat 5-37 ℃

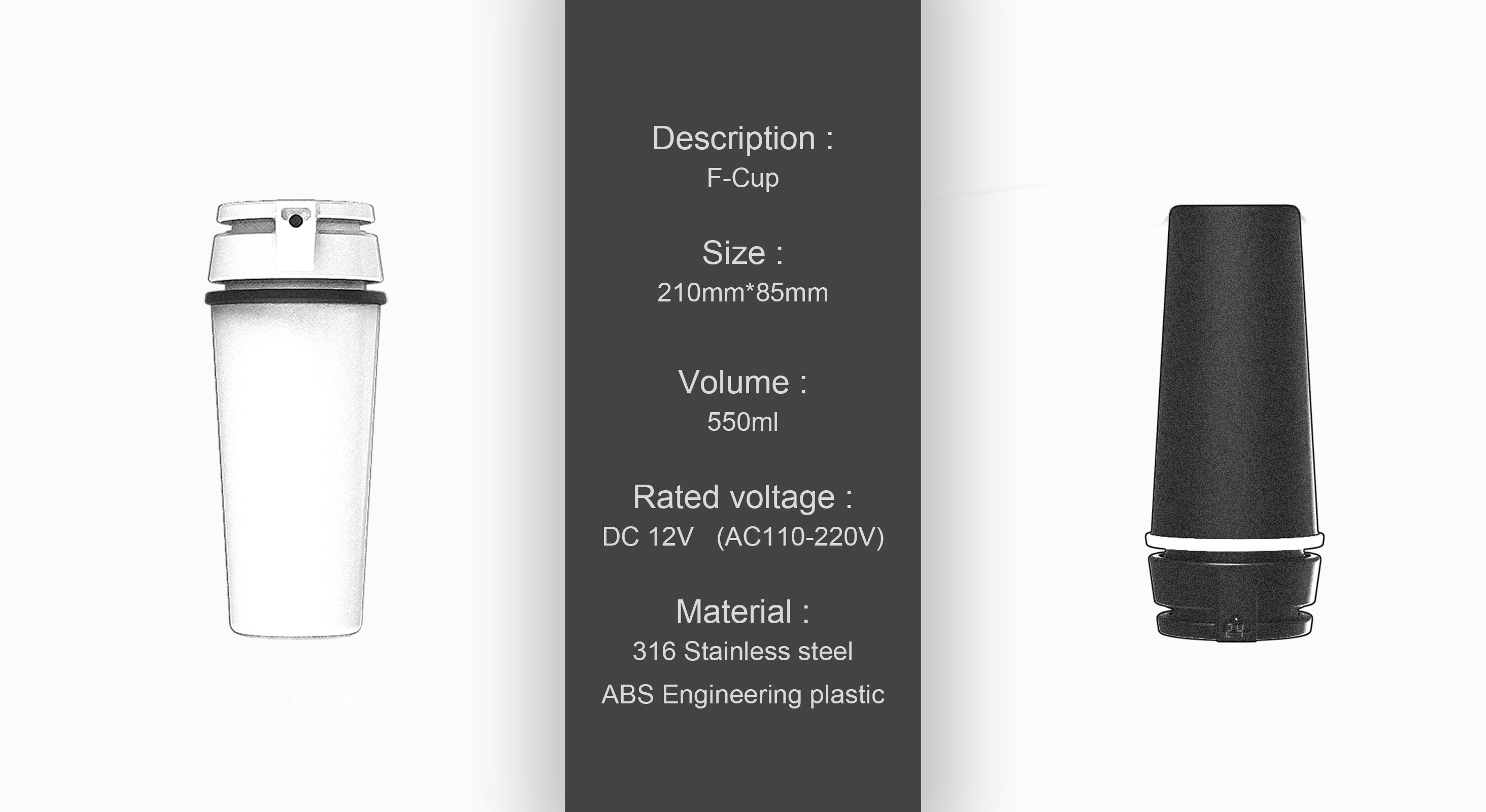

DC12V power supply mode: cooling 37-5 ℃ takes 2 minutes (70w)

It takes 1 minute to heat 5-37 ℃

AC110-220v mode: cooling 37-5 ℃ takes 2 minutes (70w)

It takes 1 minute to heat 5-37 ℃

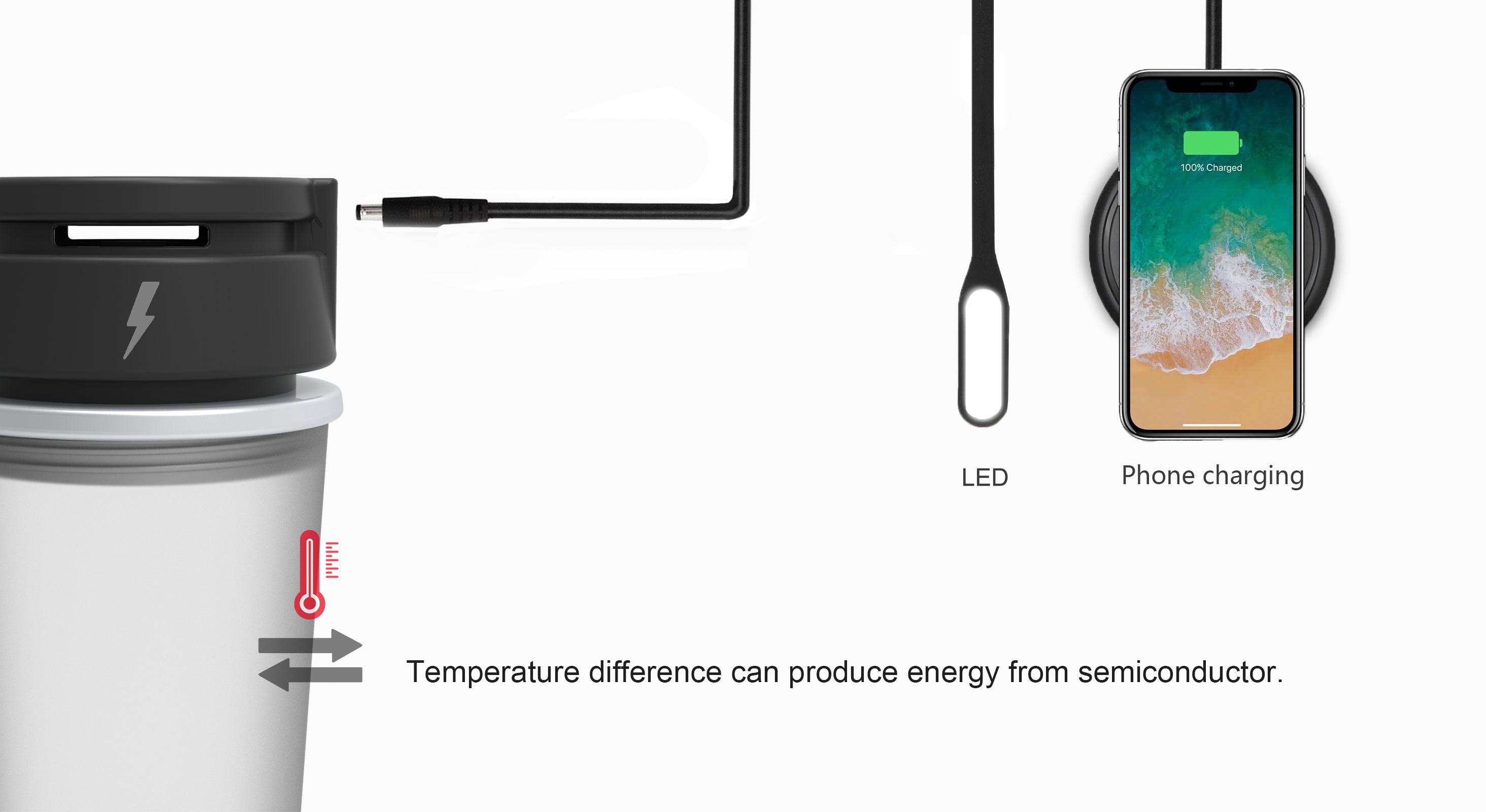

In winter, hot water is poured into the cup (ice water is poured into the cup in summer). The temperature inside the cup forms a temperature difference with the temperature of the outside air. The cup will convert this temperature difference into electric energy, which can be used to light LED lighting lamps. In the later period, we will provide mobile phone charging accessories.

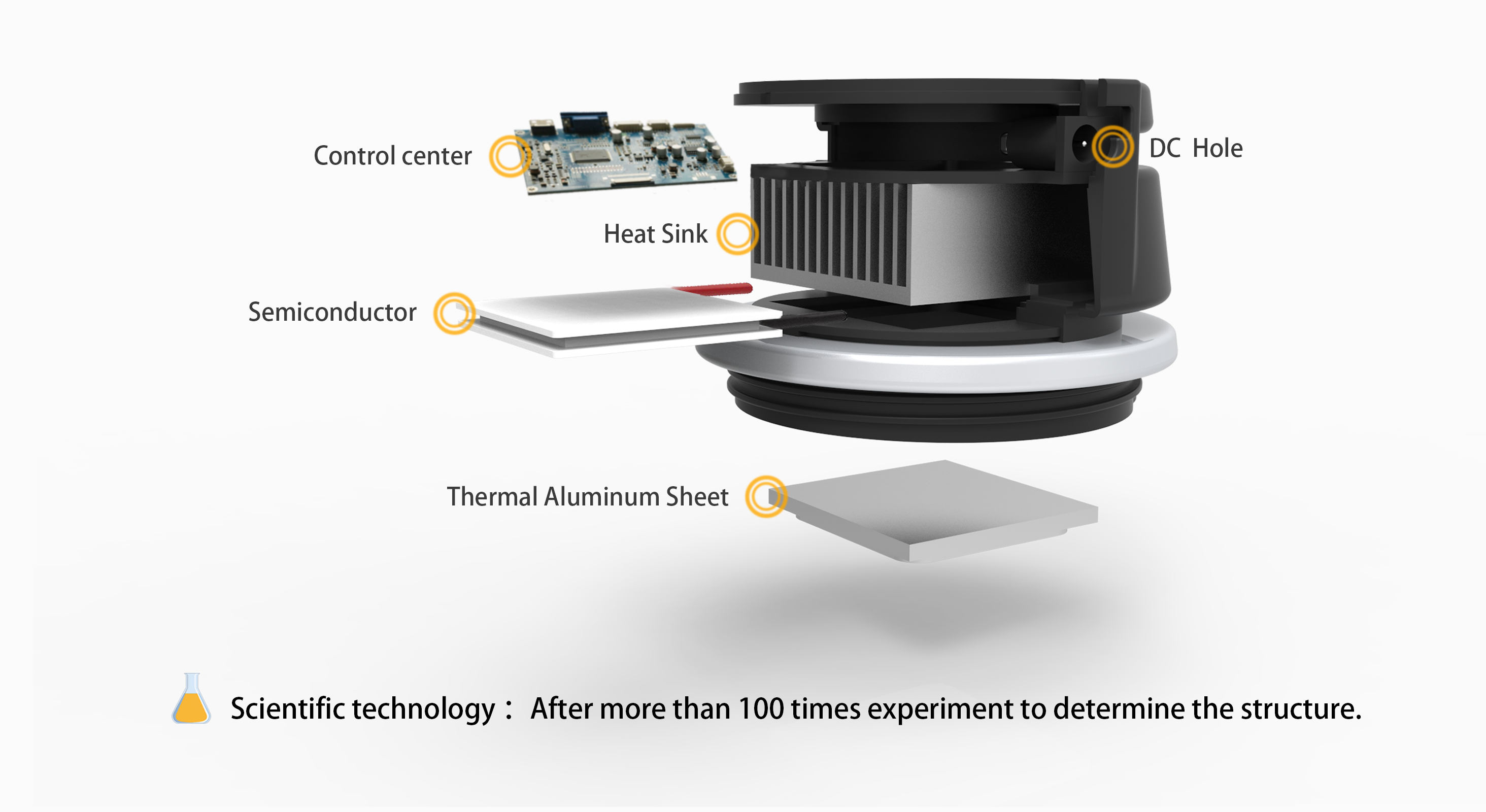

We used the simplest way to achieve the maximum function effect of temperature difference semiconductor. We did not add a temperature control system, but only used a power supply control chip to achieve the best temperature difference effect.

Because of the simple design concept, you can clean it at will without worrying about waterproof problems. Simple, reliable and efficient temperature difference

1. Problems, pain points and sources of design inspiration

The core function of the product is single (only heating or cooling alone);

Product additional functions accumulate, less practical

The appearance of refrigeration cup products is mechanized and industrialized, and the core technology of heating and cooling is inefficient and the effect is not obvious;

Some products need external devices to realize functions (the products are divided into two parts), and the scope of use and environmental limitations are large;

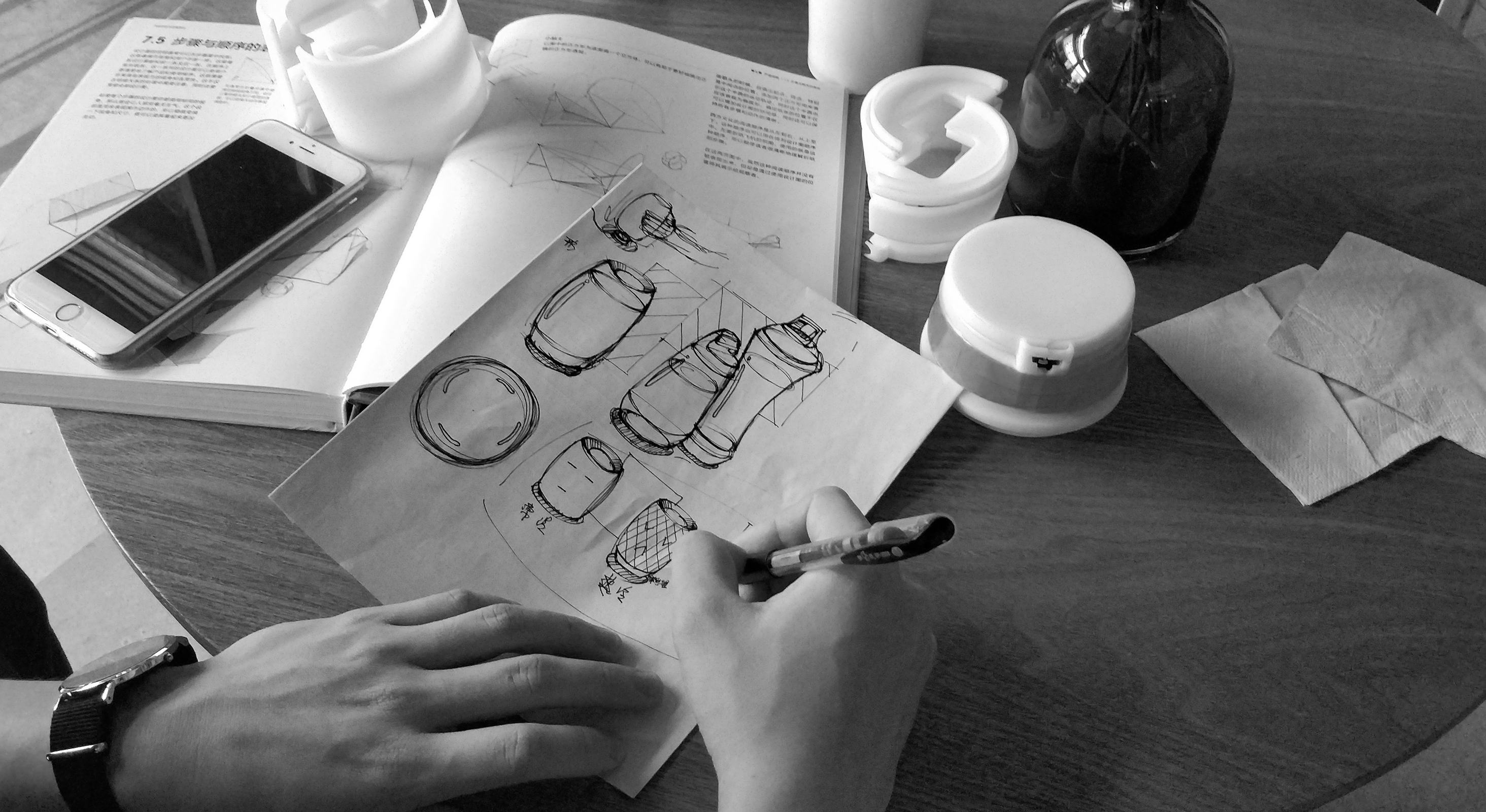

2. Design ideas and brainstorming

The integration of core functions-the water cup of the split device is not considered-the function modules are concentrated in the cup cover, and the cold and heat conduction of the cup cover to water is realized by inverting the whole cup-the wide-mouth cup-type appearance is more stable in inverted center of gravity, more labor-saving in hand-holding, and suitable for more scene placement

With.

3. Market Positioning

Mainly for the crowd: office white-collar workers, outdoor sports people, people who often go out

4. Functional Positioning

Core function: water cup that can be cooled or heated

Auxiliary functions: temperature display, temperature control (factory preset, the user can only adjust whether it is cooling or heating.)

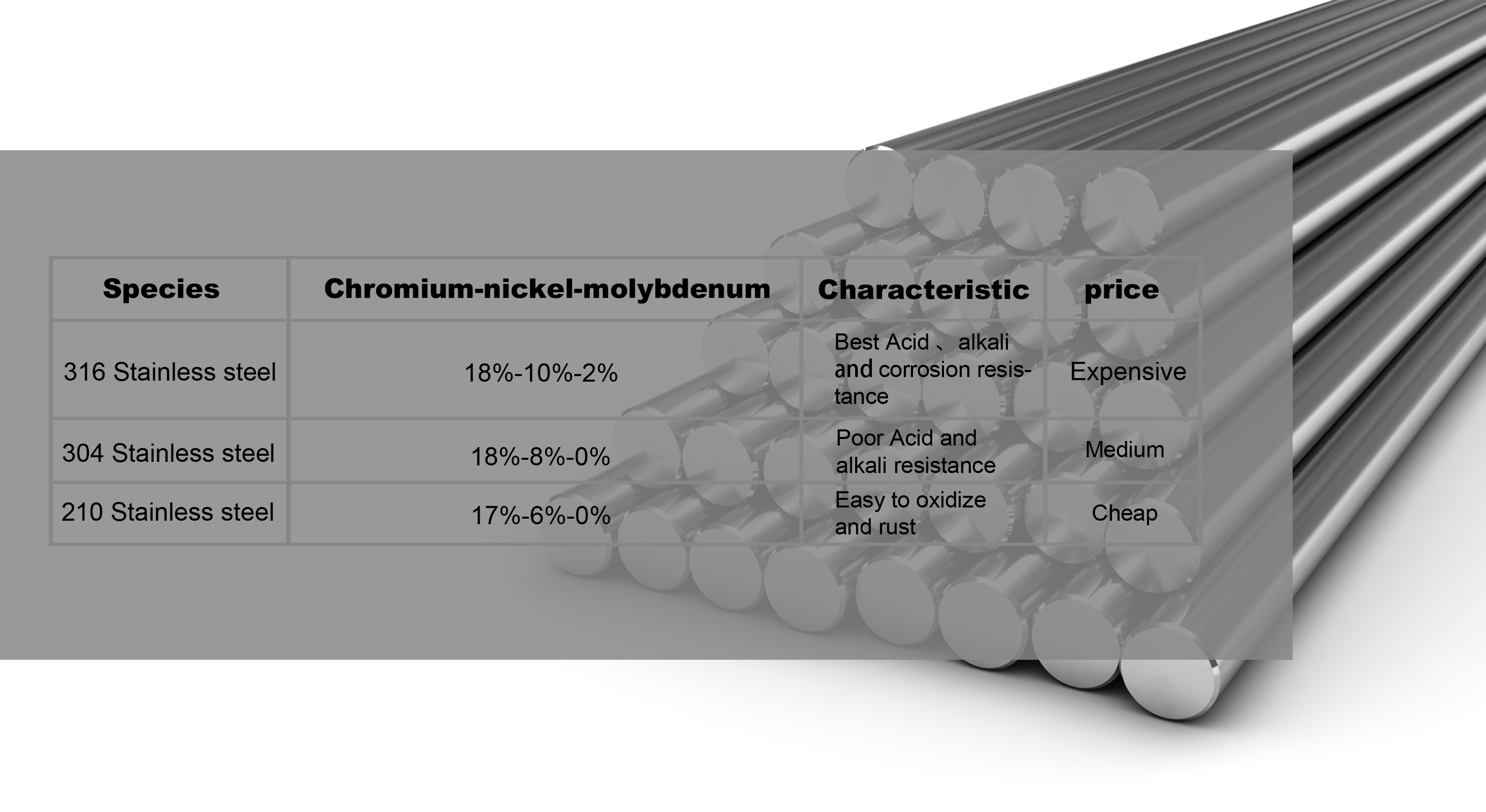

5. Material Positioning

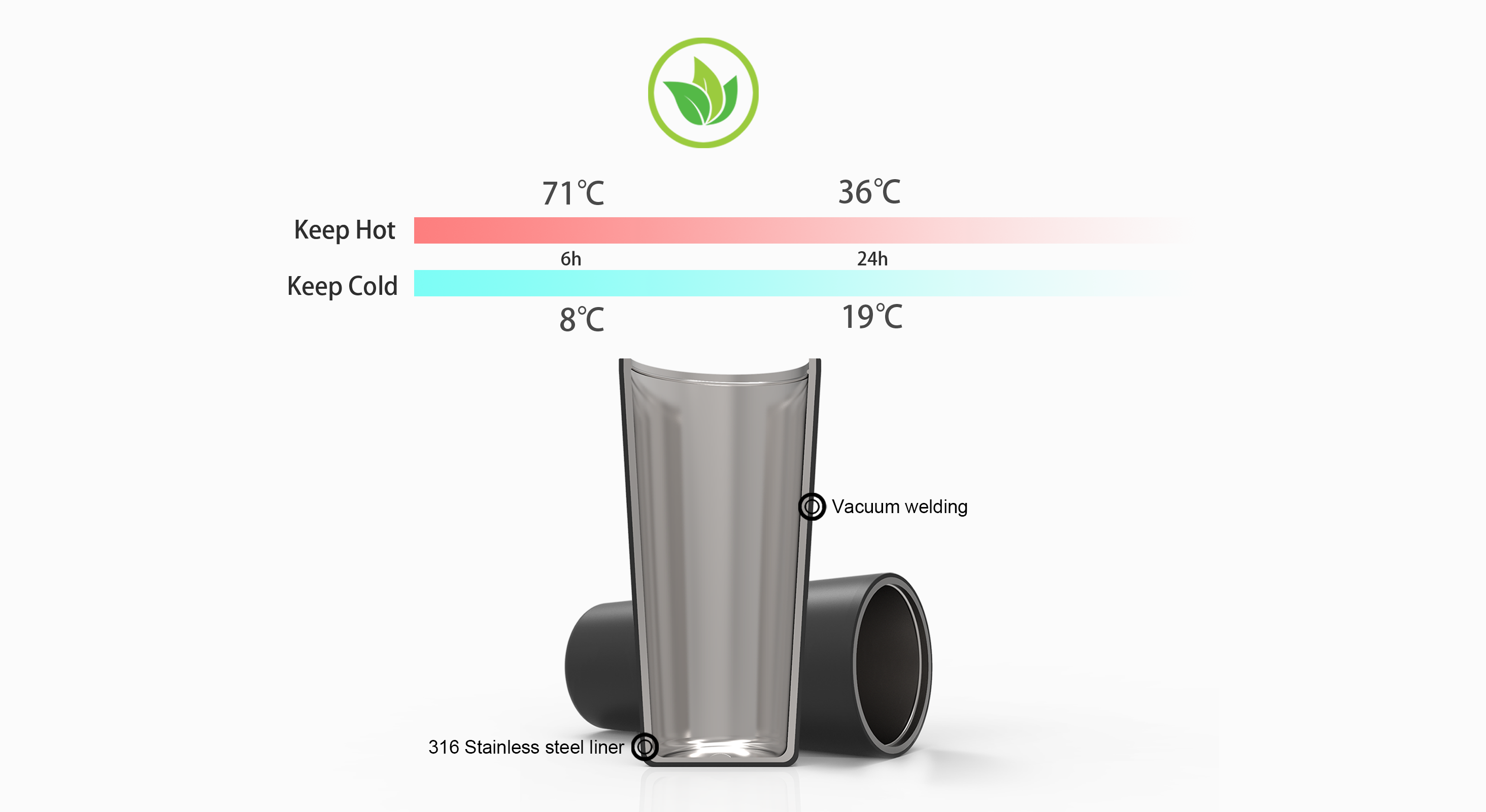

The cup lid is made of ABS plastic, which makes the whole cup light and portable while ensuring hardness and safety. The cup body is a vacuum 304 steel thermos cup body.

6, appearance style positioning

The overall appearance style is a wide-mouth cup type whole body. The unique groove tuyere simplifies the overall appearance and simplifies the visual sensory experience on the premise of ensuring the normal ventilation function.

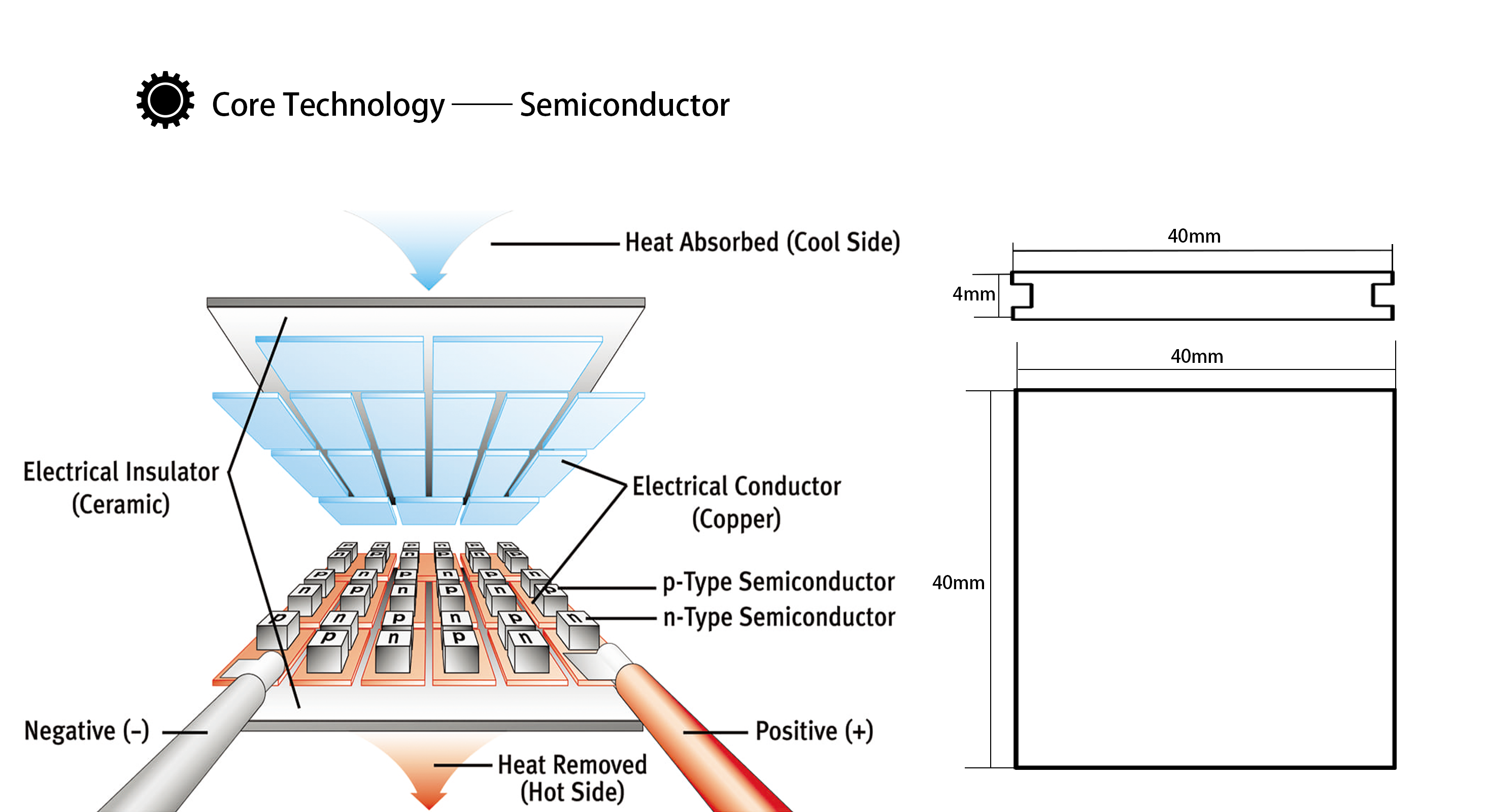

7. Core Technology

Semiconductor heat transfer technology to control cooling and heating by controlling the direction of current

8. manufacturability design:

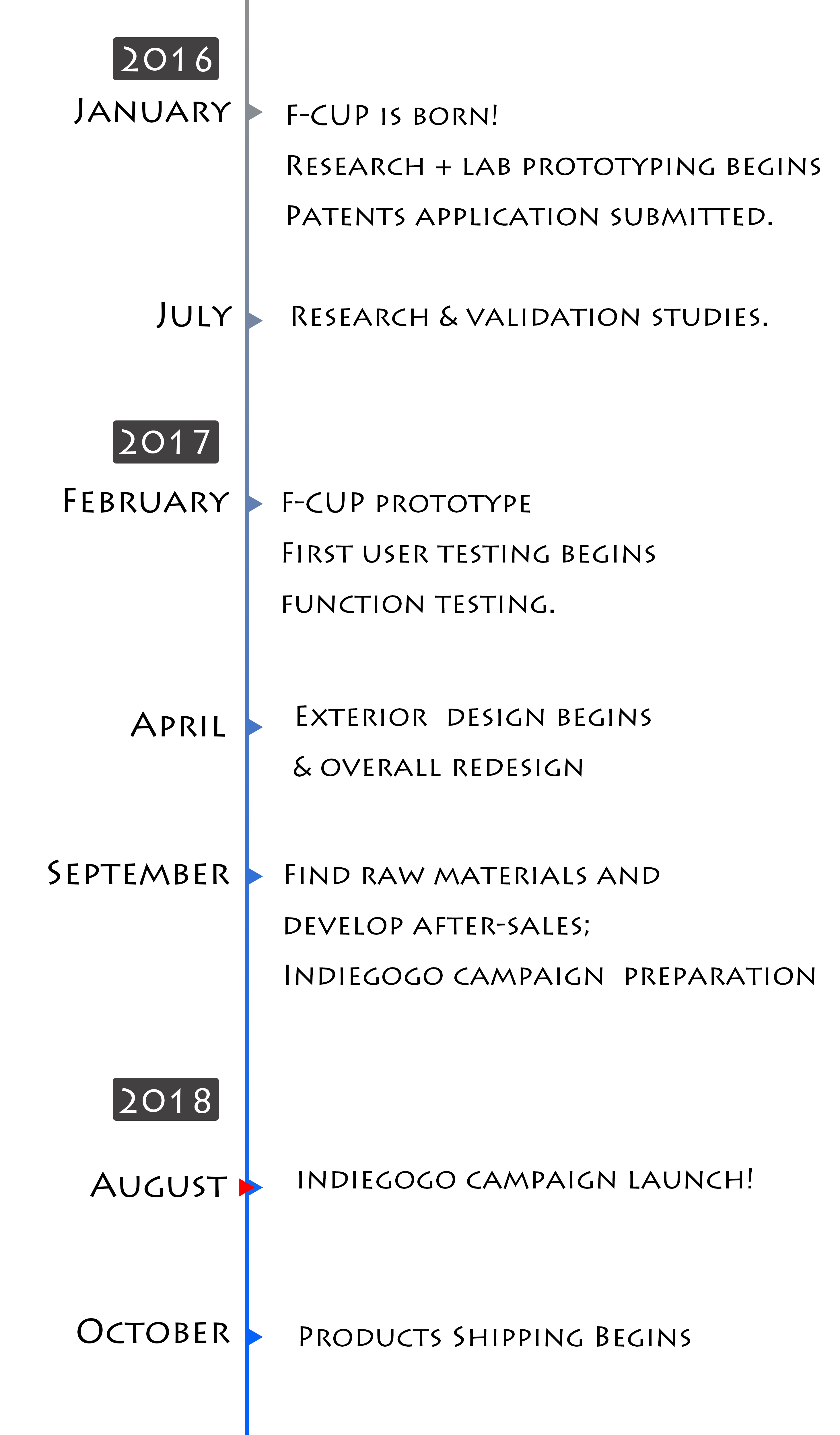

We have tested the initial prototype of Fcup at each stage to ensure its perfect operation. However, Fcups used for mass production need to be paid attention to in design to meet manufacturing requirements. Our industrial designers may need to improve some parts to better adapt. These challenges, which are normally expected, cannot be predicted beforehand with high precision. For our worthy supporters, this means that although we will try to avoid any delay, some are possible, so we must recognize this possibility in advance.

9. Production process:

Mass manufacturing is complex and involves a lot of manpower and machinery. Components must work together to complete the work on time. In this range of project management, it must be understood that the delay of one component may cause bottlenecks in the production line, resulting in greater delays in the entire process. We follow modern technology to minimize these potential bottlenecks, but we also believe that we will be prepared for unexpected events at any time. When any unplanned situation occurs, we will and will remain prepared to minimize its impact on the next milestone, and we will keep our supporters updated throughout the project.

10. Certification and license:

The Fcup we designed knows that any material in contact with beverages must meet food-grade standards. However, different countries have different definitions of these standards. One of our challenges is to obtain full certification for international sales and distribution of Fcup. We believe that the most cost-effective strategy is to interview and select a company that specializes in such international certification, and provide services for Fcup to plan and obtain the necessary certificates (food and electricity).

The copyright of this work belongs to YoYO. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Praise, good design

There is an opportunity to communicate. I'm using refrigeration semiconductors for a pet product.

Hello! Cooperative 13506793133

Hello, can we contact offline. We are looking for partners for the plan you presented.

Come on

Great!

I just raised funds on foreign websites, why not at home?

Cattle!