CMF, the organic combination of Color, Material and Finish, is a method of taking color, material and technology as design elements in industrial design. CMF requires that the color, material and surface technology in product design should be suitable for its target users, so it is necessary to consider the user's psychology, supervisor needs, the emotional nature of product color and material, and its psychological connection with people.

The Application of Color in Design

Color is the design factor that can affect the visual experience of product design most besides modeling. For consumers, color is the aesthetic element that can be felt most intuitively. With the improvement of living standards and the younger consumer groups, young consumers have put forward higher requirements for the appearance of products. It is not surprising that fast-moving consumer goods with outstanding color and eye-catching design are now. Color, as such an important component, is very important for product color value.

The Application of Material in Design

In products and environments, color can guide people's subjective visual experience, and materials have a huge impact on the effect of product design through the physical and chemical characteristics of the material itself. From the perspective of product design history, the emergence of new materials determines the progress and upgrading of design to some extent, which can create conditions for the feasibility of design implementation and bring new styles and structural forms to the design.

Application of Surface Treatment in Design

In the CMF design concept, the surface treatment represented by Finish is in the last link. Surface treatment is the tail part of product design, including physical treatment and chemical process treatment, which endows the product with a higher level of texture, texture and function on the basis of color and material. Surface treatment can enhance the connotation, aesthetic feeling and overall value of the product to a certain extent.

Among them, Apple's bold development of CMF, whether it is rose gold, champagne gold or bright black, or the tactile details of its mobile phone, has been highly sought after by people, thanks to the operation of its CMF department.

In this issue, Xiaobian takes iPhone as a case to analyze the CMF design of iPhone.

C color:

The realization of color matching still depends on the support of the process. Taking the bright black of iPhone 7 as an example, two main processes of 3D rotary polishing and magnetic fluid polishing are used, including coarse polishing, medium polishing and fine polishing, fluid polishing, black leather light harvesting, cloth wheel light harvesting and other processes. It can be seen that Apple's strict principles in color management. Silver is reserved, but material replacement is also a big challenge in color management.

Figure 5 Color Matching of iPhone 12 Non-Pro Series

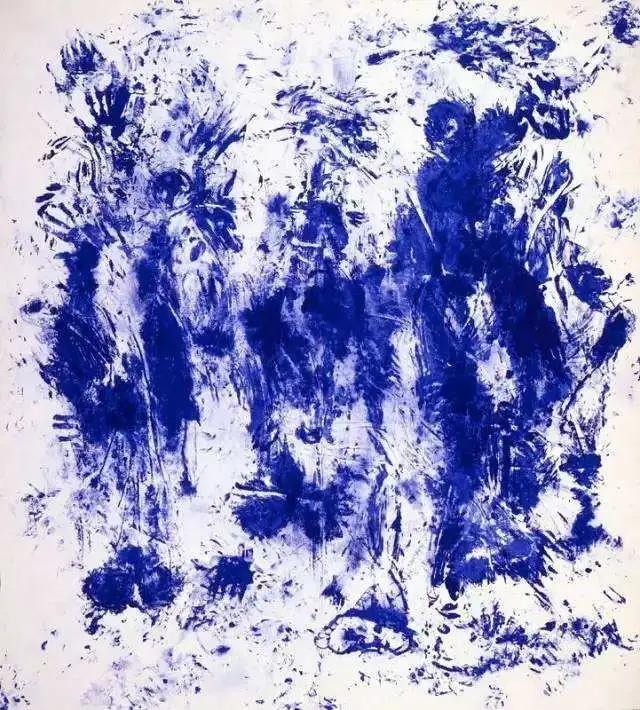

This color has been widely used in the early days and has been popular in the fashion and art circles for decades. This time it is used on the cover of mobile phones, which is a big cross-border. It will be more vivid in places with strong light. This time, the iPhone's blue spitting incident not only fired himself, but also fired "Klein Blue", and at the same time improved the brand's recognition.

M material:

Taking iPhone8 as an example, front and rear glass and aluminum alloy middle frames are adopted. The aluminum alloy back plate withdrew from the stage and the glass returned.

The glass backboard is rumored to be the five generations of Corning Gorilla, and the thickness of the strengthening layer has increased by 50%. According to relevant information, it is "six-layer dyeing process" (still need to be verified). Laser welded steel base, aviation grade 7000 series aluminum alloy frame. Coating on the surface: anti-oil stains, stain removal and anti-fingerprint.

iPhoneX the same front and rear panels are made of glass, and the middle frame is made of stainless steel. Do a seven-layer dyeing process on the glass to accurately control the color tone and opacity, and add a reflective optical layer to enhance the color. The surface is also coated: anti-grease, anti-smudge and anti-fingerprint.

iPhone12 front cover

The front cover of this iPhone12 uses a kind of ceramic reinforced glass called "ultra-ceramic crystal panel". The "ultra-ceramic crystal panel" has newly introduced nano-level ceramic crystals with higher hardness than most metals to make them integrated with glass. As most of the porcelain itself is opaque, the actual processing is extremely difficult. By controlling the crystal type and crystallinity, the hardness of the porcelain is reflected as much as possible, while maintaining the optical permeability of the material itself. Due to the breakthrough in this technology, the ultra-ceramic crystal panel has been successfully applied to the display screen. Its hardness greatly surpasses that of glass panels and is another pioneering work for the iPhone.

Back cover and middle frame

The iPhone 12 continues the new generation of physical AG technology used by the iPhone 11. The iPhone uses the same glass metal as previous generations of models. The iPhone 12 series uses a bright glass matte aluminum alloy middle frame configuration. Pro series is AG frosted glass bright stainless steel middle frame, which makes the texture of the whole product more prominent through the comparison of matte materials;

F process:

First, take iPhone8 as an example to analyze. The aluminum alloy middle frame continues to be anodized with a small antenna. If it is still the original formula, the bottom layer uses PAEK and the outer layer uses PPSU. Judging from the product renderings, color difference is still unavoidable.

The realization of glass color should be in several directions: electroplating/printing/film sticking/transfer printing. Looking at the effect diagram, the texture is more delicate, the possibility of LOGO printing with mirror is higher, and the possibility of PVD is higher.

The return of the glass back panel has given domestic mobile phones a new design space. And in the glass play, domestic mobile phones and Korean brands, played many times, very slippery. What is more gratifying is that Apple did not make too much decoration on the glass and still maintained its consistent style. The front and rear glasses are added with radians, which is more difficult than the 4th generation glass.

iPhoneX middle frame stainless steel adopts physical vapor deposition, which is what we often call PVD.

The high-brightness appearance is made by anodizing and polishing processes that include nine precision processes. Its surface hardness is the same as that of other Apple products that use anodizing treatment; however, the high-gloss surface may be slightly worn with daily use.

Two polishing methods:

Positive oxidation can be directly polished, effect, feel, better than UV.

One is the magnetorheological fluid used for magnetic throwing.

Generally, the gloss of polishing is difficult to reach Ping 7, so. This is also an embodiment of Apple's strength. To achieve this effect, all resources must be integrated.

The overall process of apple's black high brightness is: aluminum polishing into mirror surface, oxidation, polishing and AF plating.

The integral aluminum body and a precisely formed glass surface are integrated. The lens compartment is directly carved on the aluminum metal body. The antenna sneaks into the shell, making it almost traceless.

In order to create an integrated shape, a new set of processes has been specially developed to achieve a highly shiny black appearance. First of all, it is 3d rotary polishing. A special compound is used to continuously brush the appearance of fine structure, thus removing defects, seamlessly joining different materials and forming a smooth and mirror-like surface.

After that, the anode oxygen chemical process of the fuselage shell is used to create an oxidation protective layer, which uses the capillary effect to fully absorb a single-component dye and reach a saturated state as much as possible. In this way, the dye itself also becomes a component of the surface layer.

Finally, the anodized layer was polished with a immersion bath of extremely fine magnetized iron powder, and the spot was brilliant.

The entire series of the new iPhone12 gives people a delicate and beautiful feeling, which is inseparable from its continuous process technology and materials. It uses high-strength materials. The process includes ultra-precision cutting and slotting (shape), Nano injection molding (metal frame), anodized (aluminum middle frame). Here, the editor should emphasize one of its highlights-PVD technology.

The color process of the iPhone 12 series back cover (excluding the middle frame) is likely to be directly made by PVD coating, or it may be made into the corresponding color with ink first, and then inkjet it. Of course, this is only a small plait's guess. The stainless steel middle frame is wet polished PVD. The effect of high-gloss mirror plus the effect of ultra-high-precision PVD coating greatly improves the overall texture effect of iPhone. Of course, the scheme cost of PVD process is also high, including materials, manufacturing equipment, etc.

CMF Monthly

Designer's Inspirational Library-CMF Design Monthly

Insight into CMF trends

A short article is far from fully explaining the role of CMF in product design. CMF also involves the application of many elements such as various color collocation, material application and surface treatment technology. Product design requires very high comprehensive skills of designers. Only by doing a good job in CMF design can products be better.

With the continuous improvement of public aesthetics, more and more consumers have more and more demanding requirements for product color, materials, and craftsmanship. What is CMF? It is color, material (material) and finish, so when the product configuration, specifications and appearance design are certain, the choice of CMF can greatly change the tone of a product. At the moment of paying attention to beauty, the importance of CMF is self-evident.

Designers interested in CMF courses ~ Your benefits are here

Innovative Materials Museum Launches CMF Design Monthly to Analyze Popular Product CMF Design in the Market

Innovative Materials Museum has brought CMF exclusive design resources to everyone. According to the current trend of product design, CMF case analysis is carefully arranged! Let everyone learn the CMF design of the product from the case, quickly master the knowledge and application of CMF, and explore and try the product again and again. When you understand CMF, you can find the infinite charm given by CMF to the product!

The copyright of this work belongs to CMF创新工业设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Comment Board (0)

Empty comment