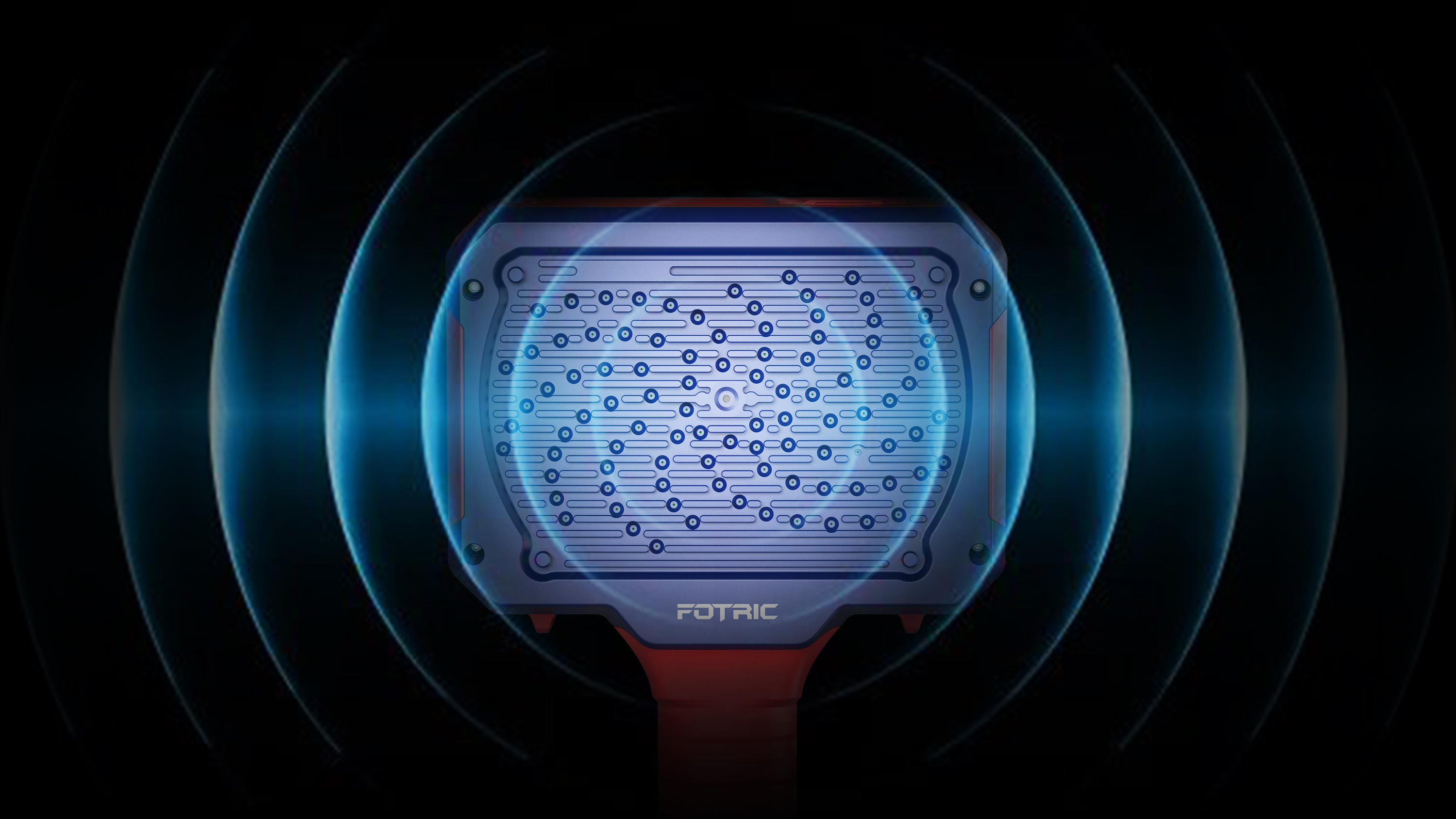

The built-in MEMS digital microphone of the sound imaging instrument can visually display ultrasonic information even in noisy industrial environments, generate accurate acoustic images, and transpose visible light digital images in real time to help users accurately identify the source of defects and distinguish problems.

The audio-visual instrument has 96 MEMS digital microphones built in, and the receiving frequency range (2 KHZ96KHZ) covers audible sound and ultrasonic waves, which can filter common background noise in industrial environment and generate clear audio images. The 7-inch touch display screen can make the display of ultrasonic information more intuitive. Remote detection can be realized up to 130m, ensuring that operators can quickly and contactlessly detect the type of local discharge generated in high-voltage electrical systems from a safe distance, minimize equipment failures and downtime caused by partial discharge and corona discharge, improve the reliability of the electrical system, the nearest detection distance can reach 0.3m, can detect some places that are difficult to reach or easy to ignore, reduce power waste, optimize equipment performance.

The FOTRIC456 adopts an integrated design, which is convenient and easy to carry. At the same time, one hand can be kept free in the detection part, which can not only ensure the safety of the operator, but also reduce the burden on the neck, and determine the severity of the leakage and the type of partial discharge in real time. The defective components can be quickly replaced before the catastrophic failure occurs, effectively preventing the power outage caused by it.

Market Value:

The FOTRIC sonograph is an efficient solution to the problem of determining high-voltage leakage sites in compressed air systems and partial discharges in high-voltage electrical systems. The lightweight one-hand grip design is in line with ergonomic design, simple and easy to operate, convenient for operators to carry out daily maintenance work, and the speed of finding problems is greatly improved compared with traditional methods, which can ensure the continuous function of power facilities and ensure the normal operation of production and operation.

The cloud vibration system can transmit the images generated by the audio-visual instrument to the cloud in real time through cloud services or big data analysis, and conduct in-depth analysis to quickly distinguish the types of partial discharge/corona, determine whether it is necessary to repair or replace immediately, and whether it is necessary to efficiently coordinate maintenance personnel online to repair and improve work efficiency.

Social Value:

Compressed air leaks, vacuum system leaks, and partial discharges are all costly and power-hungry system problems that often lead to unforeseen costs and potential production/uptime issues. FOTRIC can reduce excessive utility costs as much as possible, reduce equipment failures and shorten downtime by ensuring proper air pressure and precise positioning of partial discharge or corona in pneumatic equipment; effectively reduce cost losses, improve equipment reliability, and ensure the full use of social resources.

The copyright of this work belongs to 工业设计师-Damon. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

GOOD JOB

very good

Excellent

High-tech