Design Process and Design Analysis of Innovative Design of Fishing Underwater Visor

Project introduction

Shenzhen Chaoyufei Technology Co., Ltd. "Innovative Design of Fishing Underwater Visor"

Design requirements

Optimize the appearance and structure of the previous generation of products to enhance the brand and product competitiveness of the enterprise.

Specific content:

1. Modular combination storage design optimization of display screen and probe coil;

2. The overall design should reach IP67 waterproof grade, 1.2 meters anti-drop and dustproof;

3. Product composition: display screen, display screen shading plate, underwater probe, 15 m wire receiver, and matching fishing rod or other carriers;

4. Products should have environment: municipal pipelines, gas and oil, electricity, power field investigation, disaster search and rescue, ice fishing, fishing, etc.

5. Number of users, can be used by one or more people.

Project design start-up

After getting a detailed design task book and design requirement list, the first step we started is not to find the intention map to start the design, but to read the design task book and requirement list on the opponent in detail without leaving a symbol, because there are tens of millions of products in the industry we are involved in in the design company, therefore, the detailed interpretation of the design requirements book and the product samples given by the customer is to clear the problem points for our better project design and reduce the communication cost.

For the design requirements given above, we have identified some problems:

(1) What is the cost control of the product? What is the selling price? Section B or C of the corresponding customer?

(2) Are there any corresponding competing products or brands?

(3) Are there patents that need to be circumvented?

After understanding the problem points, we began to disassemble the design requirements list and products. By disassembling the design requirements and the previous generation of products, we understood the thinking behind the customers and the problems existing in the previous generation of products and transformed them into the design breakthrough points in our next design.

After analyzing the customer's competition, we found that:

(1) The products of the previous generation have not been designed to prevent falling;

(2) The product of the previous generation itself is a modular design. For this round of modular design, we have to break through the existing modular design.

(3) There are two ways to use the products of the previous generation: 1. As shown above, the wire receiver is spliced on the display to become an integrated hand-held use mode; 2. Separate the wire receiver from the display to form two independent bodies for use, so that the display can be installed on the fishing rod for use.

After dismantling and analyzing the products of the previous generation, the next step is to further dissect and design motivation such problem points according to the requirements in the design requirements. The product analysis environment of the previous generation is mainly fishing environment, but we have to take into account the scenes other than fishing: municipal pipelines, gas and oil, electricity, power field detection, disaster search and rescue. We found that these environments were working with bare hands and did not cooperate with other operating levers. So here we have to take into account the convenience of line collection and release when operating with one hand. Secondly, we cannot complicate the original structure of the product and increase the original design cost of the product too much.

After completing the basic analysis and understanding of the product, the next step is to simulate the entire application process of the product in these application environments. The purpose is to experience whether the product and the previous generation of products have human-machine or structural defects through the simulation process. During the simulation, we found that when the existing products are used on the rod, the storage of the probe line is very inconvenient. As shown in the following figure:(1) When rewinding and unwinding, it is necessary to bypass the top of the light shield of the display, and lift the human hand upward. (2) When working with bare hands in other environments, you need to take the screen from the left back to the palm to realize the take-up and pay-off.

After completing these analyses, the next step is to start the targeted design direction. According to the design requirements of IP67 waterproof and anti-drop, in appearance, our design choice is to go to the design style of three-proof tools and equipment, because in the previous design requirements interpretation, we learned that most of the application scenarios of this product are industrial environment.

Secondly, in the design point for modular design requirements, we initially want to optimize the coil receiver by changing its usage. In the previous use process simulation, we have found that there are human-machine and operation problems in the existing products. At this design point, our idea is to change the use of the coil receiver to the problems that occurred in the previous generation design. In the simulation, we concluded that if the receiver is on the side of the screen, there will be no problems found in the above simulation when the fishing rod or a single person is used alone. For example, it is the same as the collection of fishing lines on our fishing rods.

In the breakthrough and integration of these design points, we must meet the two basic points mentioned earlier. First, the manufacturing cost cannot be greatly increased. Second, keep the use mode of old products: 1. It can be used on fishing rod or operating rod; 2. It is to disassemble the display and coil and install it on the operating rod. Design optimization is carried out on top of these two methods.

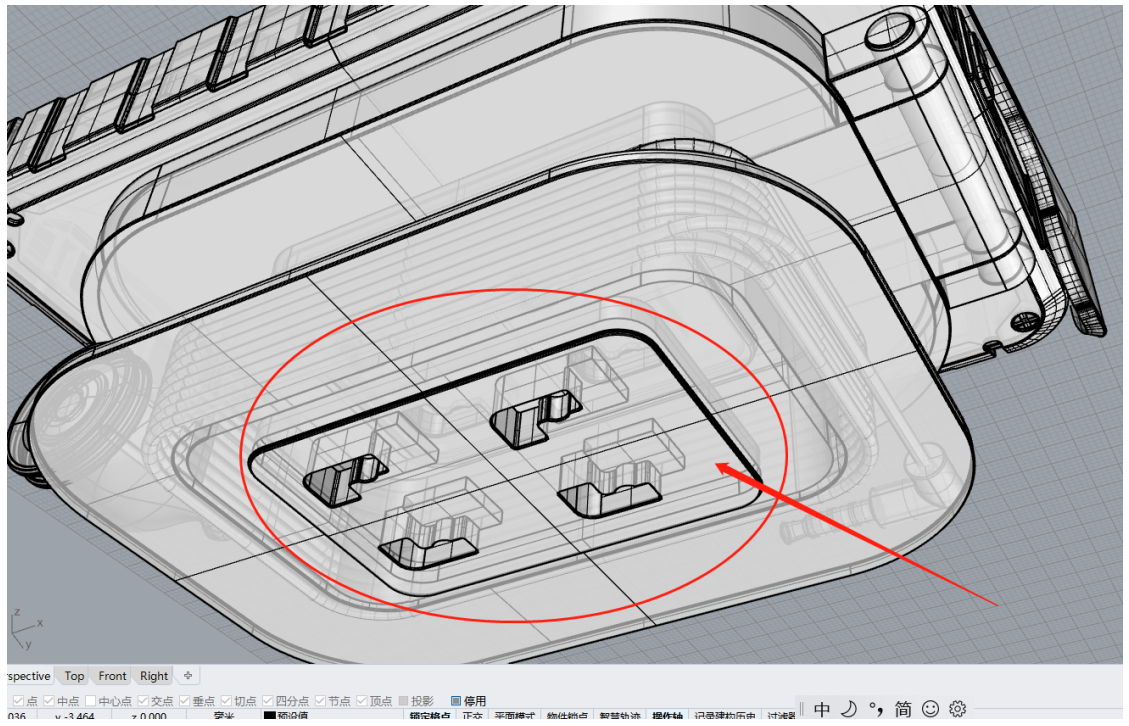

On this design difficulty, after dismantling the old products, we found that the shaft in the middle of the coil receiver is hollow, which is the place where we can design and utilize. We meet the necessary conditions for solving the pain points of our products and designing improvement points by changing the shape of the intermediate shaft of the receiver.

Scheme design direction

After the disassembly of the product design requirements in the early stage, the decomposition of the product disassembly machine and the simulation of the use process, we set the design direction as: by changing the use mode of the retractor to break through the disadvantages of the existing products, and by optimizing its use The way to meet the rationality and practicability of man-machine in a specific operating environment.

Program design and implementation

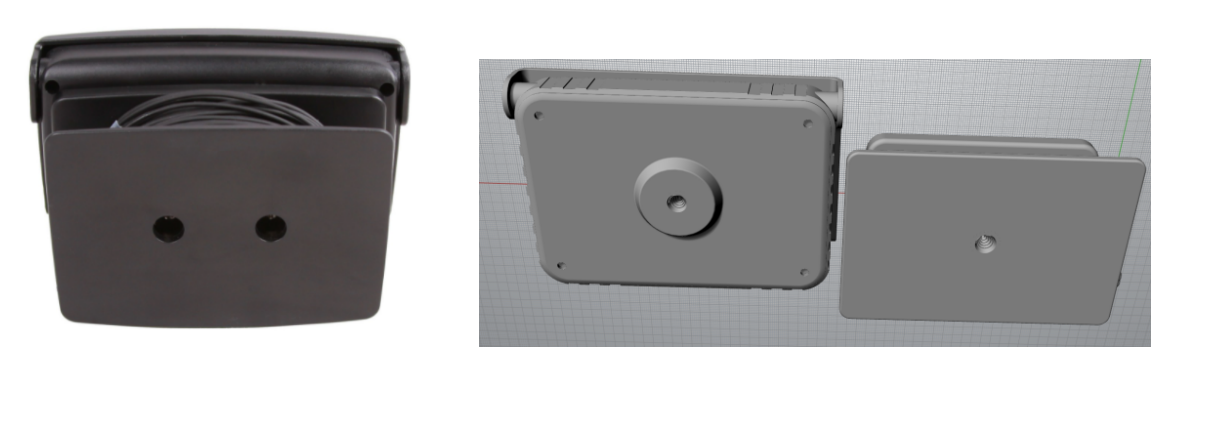

(1) In appearance, we adopt the style direction of three-proof industrial tools and equipment, and carry out secondary injection molding on the shell to meet its 1.2-meter anti-drop requirements.

(2) We have retained the design points of the previous generation of products on the shading plate.

(3) Regarding the design of the retractor and the design requirements of the module, we adopted the upgrade design on retaining the two usage methods of the previous generation of products: in the usage of the retractor, we extracted the retractor on the fishing rod because it is more ergonomics: the left hand holds the display part, the right hand can perform the action of rewinding or pay-off according to the contents on the display (as shown in the figure below). The principle is to add a damping bearing on the upper right side of the upper wall of the retractor, so that the rewinding coil can be opened to the right by 90 degrees, thus achieving the reasonable action of rewinding and pay-off with the left hand and the right hand of the machine.

(4) In the installation method, we retain the original installation hole on the bare metal and the installation hole at the bottom of the wire retractor to meet the modular design in the design requirements, and realize the original characteristics that the bare metal can be installed on the operating rod and the main machine can be installed on the operating rod after being combined with the wire retractor in a specific environment. At the same time, we have also added a mounting hole at the bottom of the upper wall of the retractor (as shown in the figure below) to meet the requirements that the retractor can be installed on our specific operating lever after opening the 90-degree angle operation mode. From the operation process, it is more in line with our reasonable behavior when fishing.

(5) In the control of manufacturing costs, we mainly make a breakthrough on the wire retractor, by adding a wall thickness and a damping bearing to change the pain point and man-machine irrationality of the product, by changing the use of the wire retractor, let the product enter a new user experience, enhance the sense of mission and application value of the product. The increase in its manufacturing costs is also controlled at a very low rate. At present, this product has entered mass production and will be listed soon.

There are still many projects that design innovation and development processes like this. This project is only one of the many design projects in our white fox industrial design. In this way, through analyzing the actual needs of customers, we can gain insight into the purpose behind the customer's design upgrade and decompose the problems existing in the customer's products, through experiments and user experience simulation to explore the relevant product pain points and product upgrade design points to carry out breakthrough design projects, in the white fox design company every day. Let's continue to look forward to the birth of better product design.

The copyright of this work belongs to Shenzhen White Fox Industrial Design; Shenzhen Chaoyefei Technology Co., Ltd. Anonymous reprinting and personal use are prohibited, and the original author must be contacted for any commercial use.

The copyright of this work belongs to Design FU. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Is the winding cylinder smoother. Can the left hand grip make some colloidal materials. There is a lot of mud and water to do this work. Whether the screen part can be better managed, it is easy to accumulate mud with more bumps and bumps. Whether the two sides of the upper cover and the interface can be waterproof. Immature ideas

If you think it is possible, you can give the younger brother a triple hit, so that the younger brother has the motivation to follow the liver

Good design

Clear organization and clear thinking

This design is too professional

Can be sent into an article