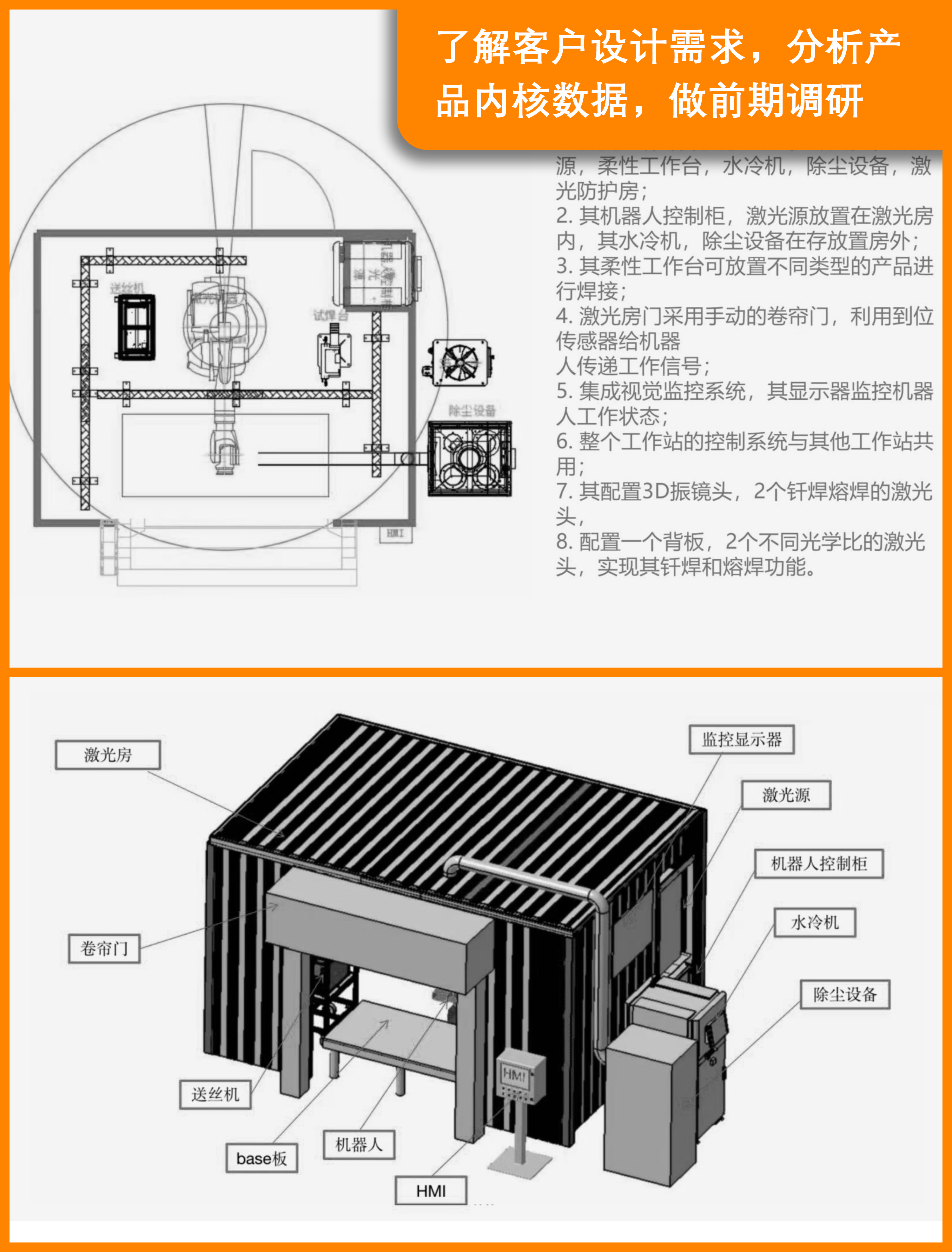

1. Robots

Receive the signal from the control cabinet to make the welding grab reach the welding position, etc.

2. Robot control cabinet

Receive external signals, such as welding, teaching pendant, external control cabinet, etc., and transmit the data to the robot to enable the robot to complete the welding task.

3. Welding torch

The welding torch uses the high current of the welding machine and the heat generated by the high voltage to gather at the welding torch terminal to melt the welding wire, and the melted welding wire penetrates into the part to be welded. After cooling, the welded objects are firmly connected into one body.

4. Welding power supply

The purpose of using the high-temperature arc generated when the positive and negative poles are short-circuited in an instant to melt the solder and the soldered material on the wire and combine the contacted objects.

5. Wire feeder

Under the control of the microcomputer, the automatic wire feeding device can continuously and stably send out the welding wire according to the set parameters.

6. Wire feeding tray

The coil is filled with welding wire and fixed on the robot, so that the robot can produce wire more freely when moving and welding.

7. Transformer

Used to convert voltage

8. displacement machine

The weldment is driven by the motor to rotate and stop, so that the weldment reaches the appropriate welding position, and the auxiliary welding is completed, which is controlled by the external control cabinet.

9. Gun Clearance Station

Complete the welding torch to clean up the welding slag, spray anti-spatter liquid, and trim the welding wire. Is the welding effect to achieve the best.

10. Welding fume purifier:

Welding fume purifier is used for the purification of fumes and dust generated in welding, cutting, grinding and other processes, as well as the recovery of rare metals and precious materials. It can purify a large number of fine metal particles suspended in the air that are harmful to the human body.

11. External control cabinet

Control the displacement machine, the motor parameters, and transfer the data to the Fanuc control cabinet.

12. Dust hood and suction pipe

Smoke and dust are sucked into the welding fume cleaner through the fume hood and suction pipe to filter the air.

13. Equipment table

A table for storing equipment.

The copyright of this work belongs to 圆塔工业设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Can I share keyshot information 15022285520 V

That's great.

good and detailed

yes

Thanks for sharing.