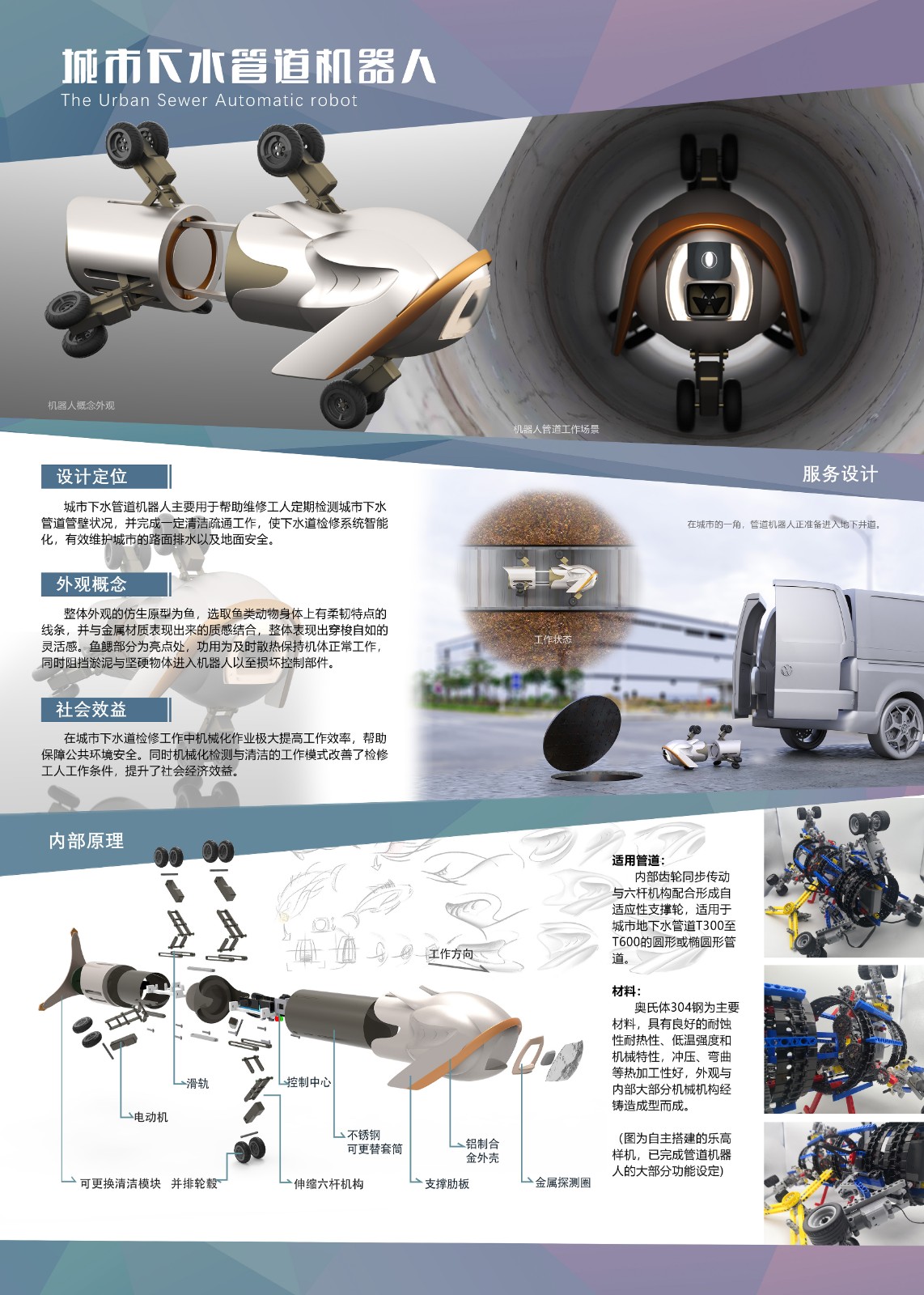

Appearance description The bionic prototype of the overall appearance is fish. The lines with flexible characteristics on the body of fish animals are selected, and after combining with the texture of metal materials, it can show the feeling of shuttle freely, and it can visually show The flexibility of the pipeline robot in the groundwater pipeline; in addition to the lines obtained by the bionic fish, the mechanical principle structure is retained to a certain extent in appearance: the part of the fin is the placement bracket; the power wheel is completely retained for safety reasons; the overall three-section disassembly and assembly: the head wheel, the connecting part, and the tail wheel; each part is independent and detachable; the connecting part can realize 360 ° surround steering by using a four-bar mechanism. The application scenario is placed at the manual detectable entrance of the main hub of the groundwater pipe, and is applied to the groundwater passage in the daily urban planning stage, diversion and maintenance stage, and is mainly placed at the hub of the groundwater pipe with dense flow of people and vehicles. Through regular inspection work, the loopholes and blockage of the groundwater passage can be found in time to avoid the danger of ground collapse. The creative explanation of the adaptive telescopic wheel internal gear synchronous transmission and the six-bar mechanism cooperate to form an adaptive support wheel, which is suitable for the two sections of the circular or oval pipeline of the urban groundwater pipeline T300 to T600. The body can realize the passage of the pipeline turning, and also effectively avoid the problem of friction damage to the robot caused by the pipe wall during turning. The four-bar mechanism of the connecting part of the connecting mechanism can realize the relative rotation of the two bodies at 360 degrees and the rotation in the up and down directions. The four-bar mechanism is composed of two sets of parallel rods and sliders, which cooperate with the circular track on the connecting part to make it more flexible to rotate and realize the turning behavior. The circular track of the connecting mechanism is shown in the figure. Working skeleton ring skeleton, the main working area is supported by three wheels, which is more stable and can be used to survey the pipe wall condition: cleaning method The robot body can be replaced with three different modules of cleaning devices: (1) steel zigzag single piece (used to mash solid blockages); (2) soft wool single piece (cleaning pipe wall or solid liquid blockages); (3) chemical dumping box (blockages that can be cleaned by chemical reaction) Compared with cleaning robots on the market, the modularization of cleaners is realized in different application scenarios, and users can use different modules for cleaning. Each module exists independently, that is, it can be disassembled freely and is easy to clean.

The copyright of this work belongs to Sang.mq. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Comment Board (0)

Empty comment