In November last year, a project came up with three plans. After the revision, the customer selected the following one. The structural engineer also drew the structure. Finally, after the evaluation by the mold factory, the customer was shelved because the cost exceeded the budget... Very hurt...

The first time I came into contact with the design of sheet metal products, I didn't know how to start at first. After listening to the boss's explanation in detail, I began to search for various words and pictures of solar street lamps on the Internet with a little confused mind.

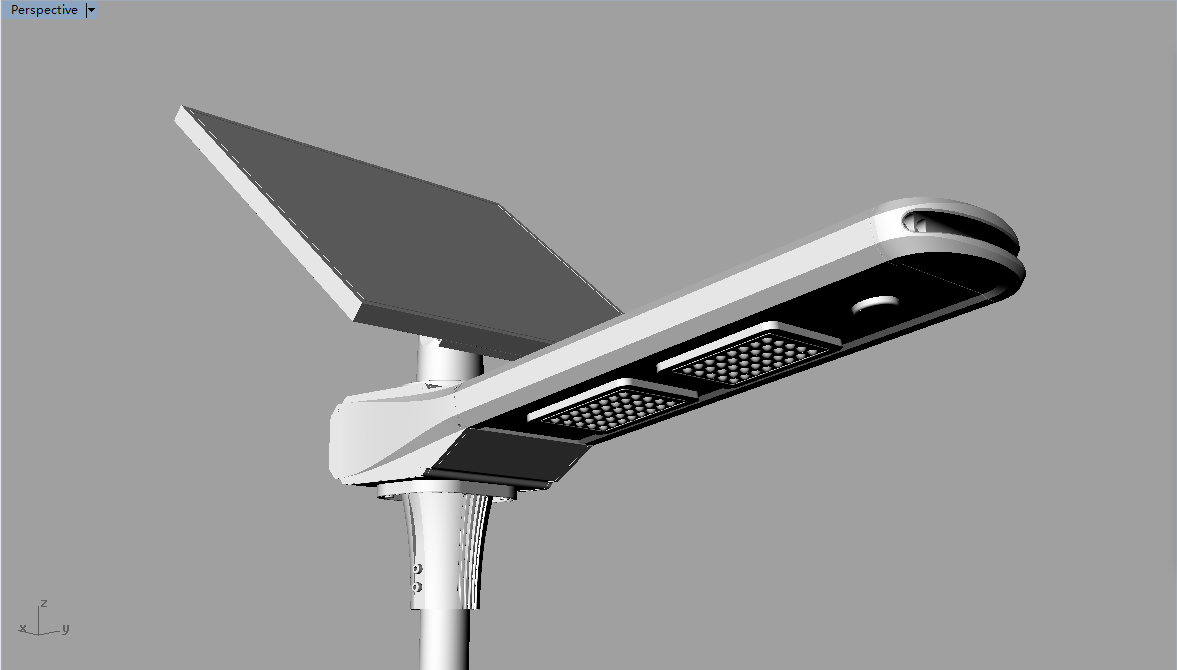

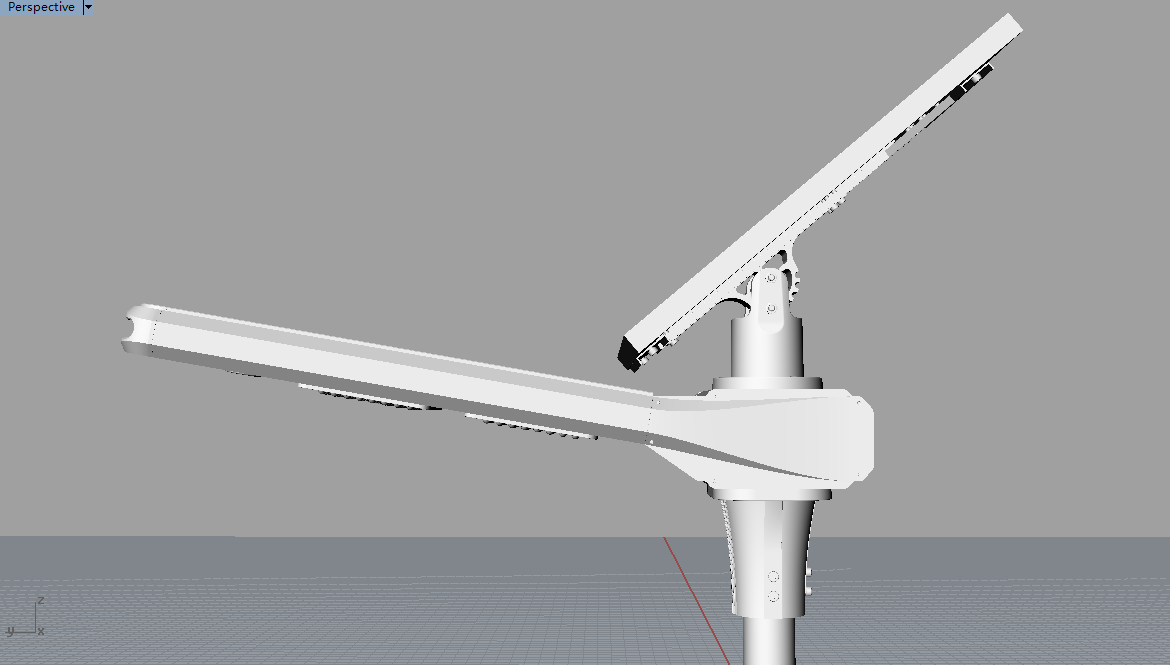

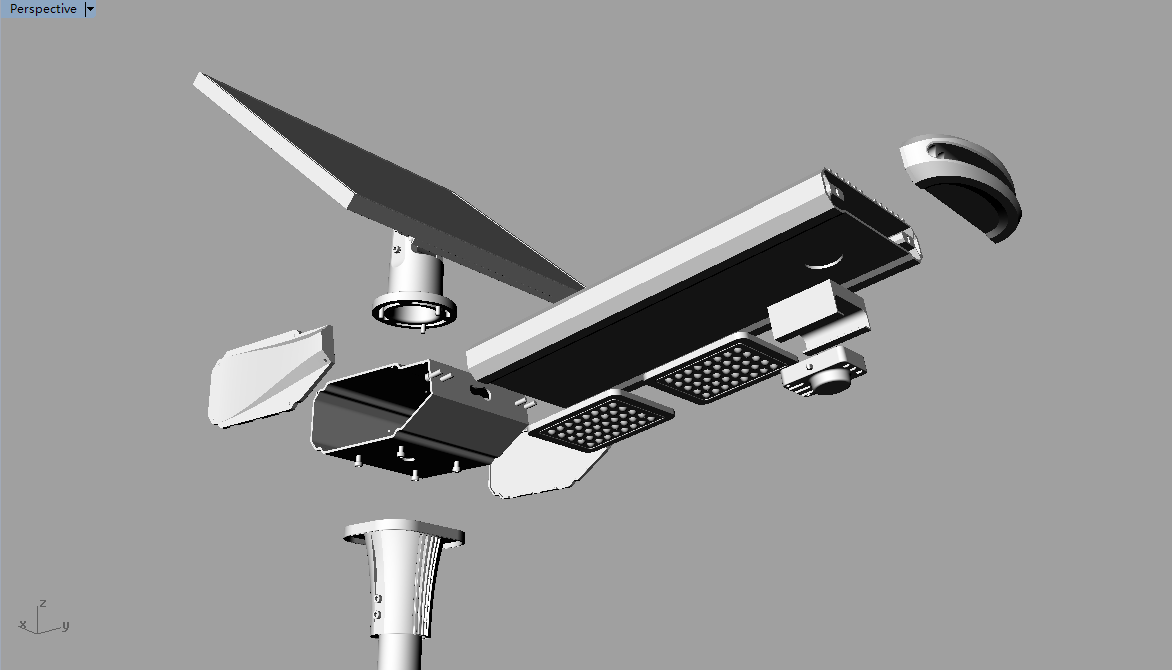

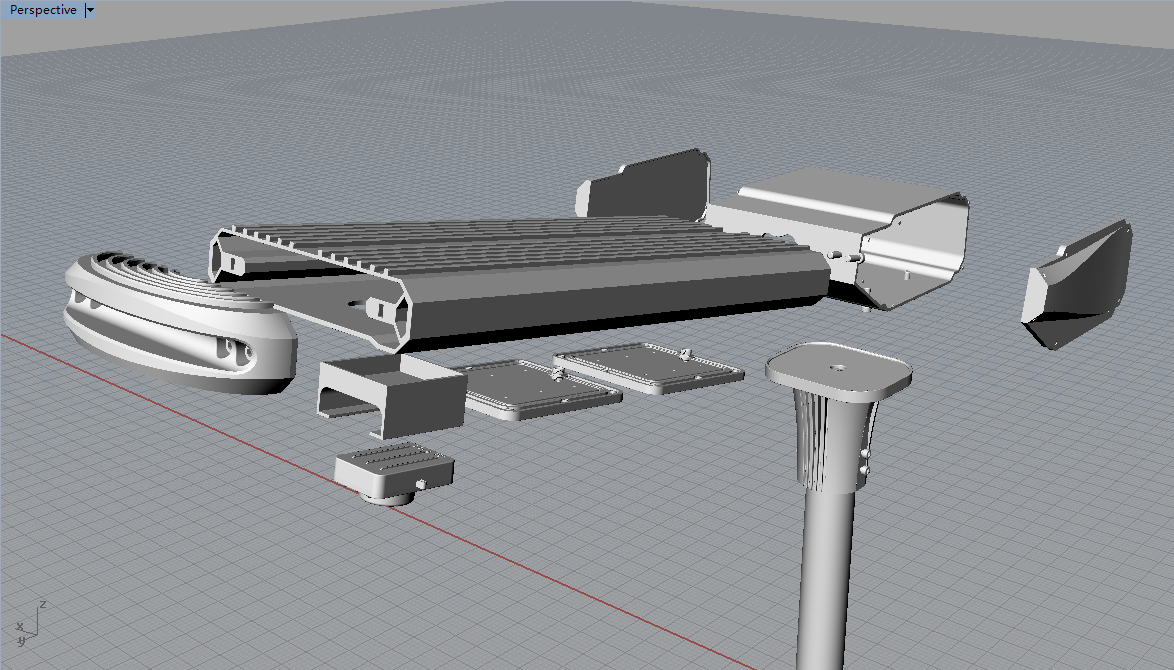

The design requirements are not complicated either. The customer requires that the main body is a profile, I .e. the front lamp slot and the rear battery compartment cannot be made into die castings. The sheets on both sides of the battery compartment are made of PVC plastic. The rest, such as plugs and the piece connected to the lamp pole under the battery compartment, are made into die castings. The solar panels above are ready-made and need not be designed again.

Although the project has been shelved, it is a new breakthrough for me to come into contact with the design of sheet metal products for the first time. Come on, SAO Nian ~

The modeling design is mainly tough and atmospheric, with various line element changes, and innovation is made on the basis of the principle of cost first. It is necessary to consider the design innovation points in each location and control the integrity of the product.

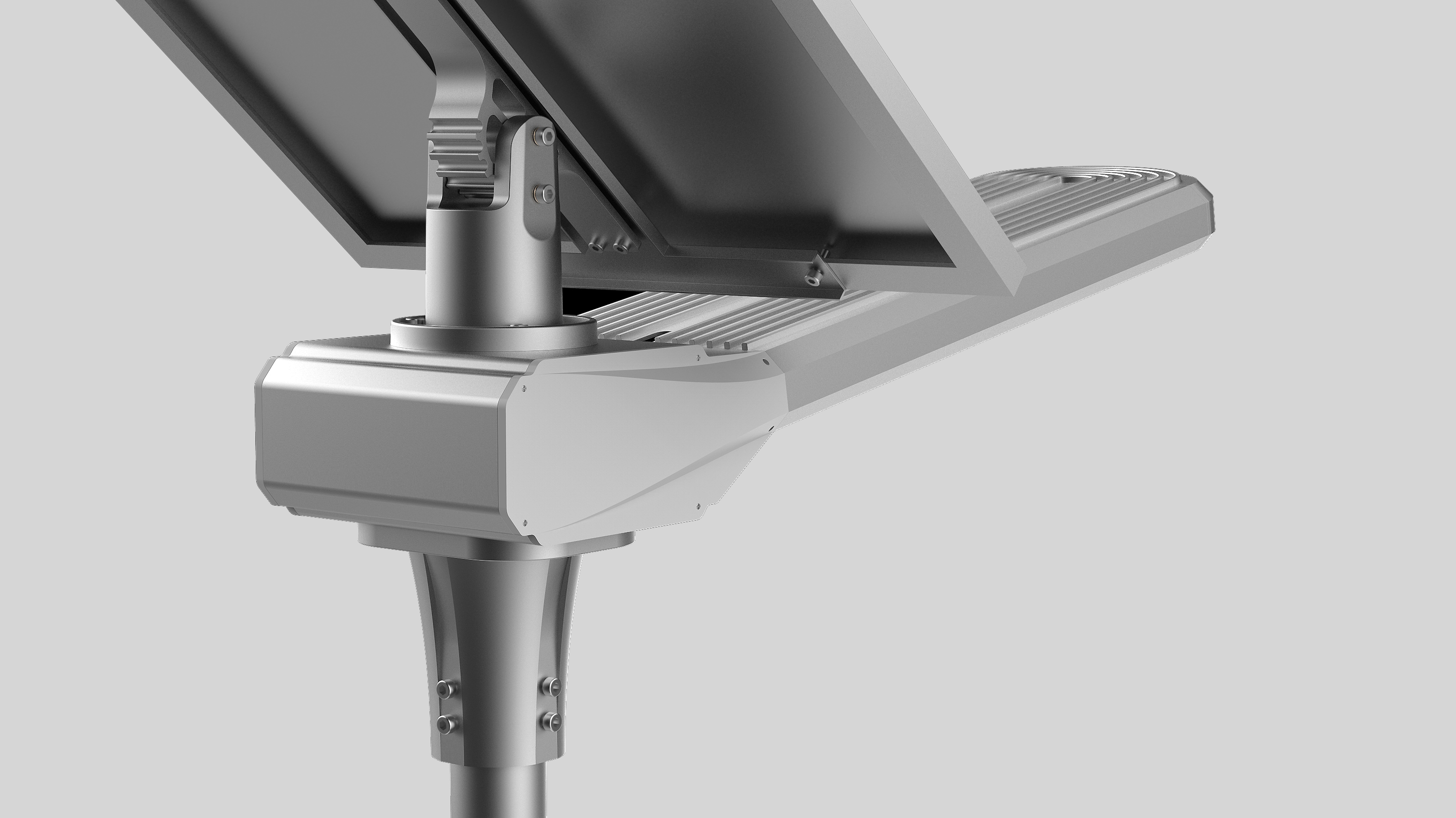

The prism design above the lamp slot not only plays a decorative role, connects the lamp slot (profile) and the plug, maintains continuity, highlights the industrial feeling of the product, but also plays a role of reinforcing ribs.

Because the model is relatively large, I reduced the model by ten times compared with the same period of last year before rendering. It is still a relatively large model. Rendering is still a little difficult for me who polished the slag. In addition, the metal material itself is easy to expose, so it took a lot of time to adjust various values in the keyshot.

Simple rhino model disassembly drawing (without structure).

Finally, welcome your advice ~

The copyright of this work belongs to 林蹦哒. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

This cost is really a bit high, it is estimated that it is not as cheap as one-piece die casting.

Is there no development budget before the design?

It is not easy to assemble, it is not easy to produce, it is not easy to spend, and the cost is high.

The battery compartment has a large load-bearing capacity and should be changed to die-casting.

To introduce to you, I am Party A...

Just as my company also did a street lamp project

My feeling is that you are really a little more complicated.

Hale and hearty is enough, but the atmosphere is not enough. The surface is cut too much and looks broken, so it looks stingy.

Generally, it will require the whole, add some details, not too weird, too many details will feel broken, no details is lack of design

The heat dissipation fin on the top surface is too thick and not high enough, which has no effect after increasing the cost. This is the feedback given to us by Party A.

Another is that the wall thickness cannot be too thick because of the cost problem. The other is the safety problem. We should try our best to reduce the weight. When I did it, Party A directly stipulated the heaviest weight of the street lamp. If something hanging so high falls off, the lighter the better. Reduce material on the wall thickness, reduce weight at the same time with high strength. I don't know if you have any requirements for this.

The groove on the front of the lamp holder feels that it is designed for design, and it is not of great practical use. Our screw holes are below to prevent water accumulation

There are many plans. The plan that can land depends on Party A's mood. Ha, ha, ha

mutual encouragement

The solar support is made of hardware mold, the main body of the lamp is made of a die-casting mold, the lighting part is made of aluminum profile, the light source should be modular, and a PC plug at the top is made of imitating metal texture.

The above is too complicated, the cost is high.

The rendering is very textured, and the cost of mold opening is very high.

Come on, SAO Nian ~, ha ha