Item Name Press Ice Cube & Ice Puck Mold

Chocolate Design

Design Time 2022-10 Listed

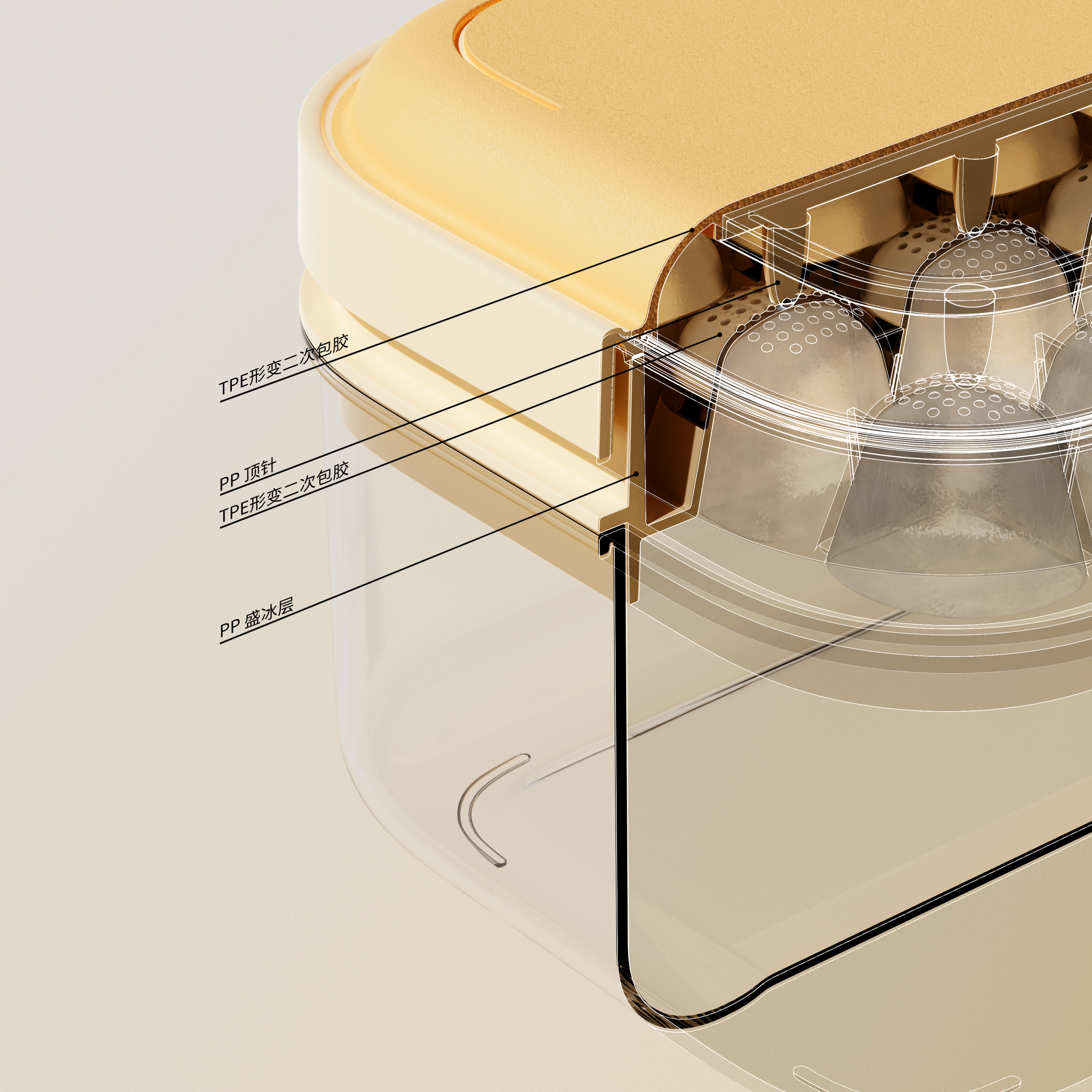

The main body is divided into three parts: press cover, ice making layer and ice storage box

Ice-removing step: turn over the ice-making layer, and press the deformable adhesive layer of the upper cover by hand to extrude the ice cubes in the ice-making layer into the ice storage box;

Dynamic diagram of ice removal principle: the lid before pressing is in the initial state, and the appearance is full; the lid after pressing is in the deformation state, and the thimble squeezes the ice-making layer to seal out the ice; release the hand and restore to the initial state;

Static profile of ice removal principle: the pressing cover adopts TPE secondary encapsulation to fix the PP top plate and the annular support cover on the side, and can realize up and down pressing deformation at the same time; The thimble on the top plate is in a critical state before pressing, and the thimble is pressed to squeeze the adhesive surface of the ice-making layer TPE to deform and make the ice naturally fall off;

The above figure is the static diagram of the force after the palm is pressed;

At the same time extended a series of ice hockey mold;

Adopt TPE soft rubber cover and PP plastic soft rubber de-icing form;

Single-layer, double-layer, with PET ice storage box and other combinations for users to choose;

Ice cube ice hockey mold sub-drawing, in the design of addition, put forward the playability of pressing off ice; Subtract in cost, remove redundant design, pay attention to functionality and practicality;

The above picture shows the hand plate sample, T0 and T1 photos. There is no double-material injection molding machine that can only perform secondary injection molding, but it is difficult to perform secondary injection molding of soft rubber and two PP plastic parts. However, the factory lacks experience and the structural design of the all-inclusive rubber cover almost overturned, resulting in repeated adjustments for nearly a month to reduce the defective rate. PS: Double-material injection molding is preferred when the cost permits;

The copyright of this work belongs to 朱古力设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Have a patent?

Do you sell this at home or abroad?

this is good

Excellent

666

I'll have an iced coke

6666

very good