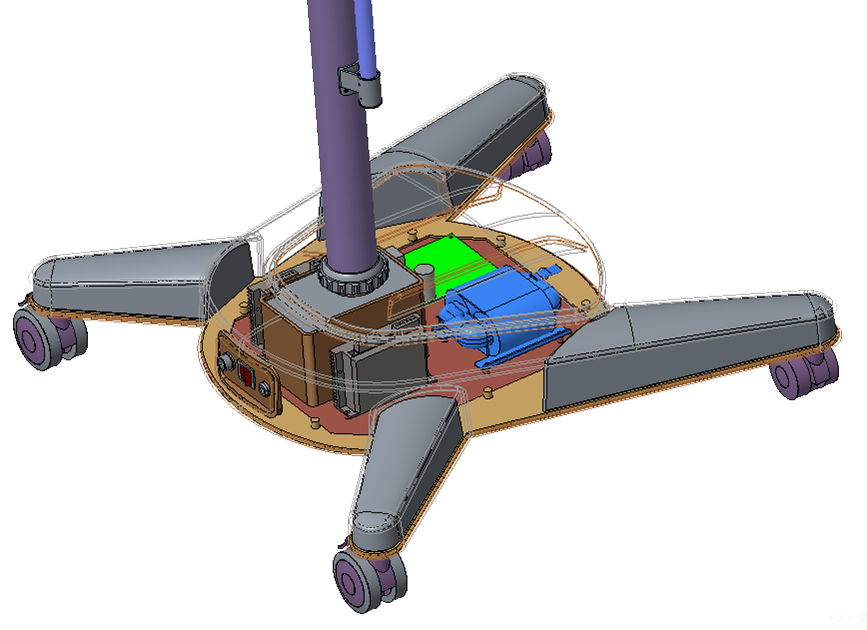

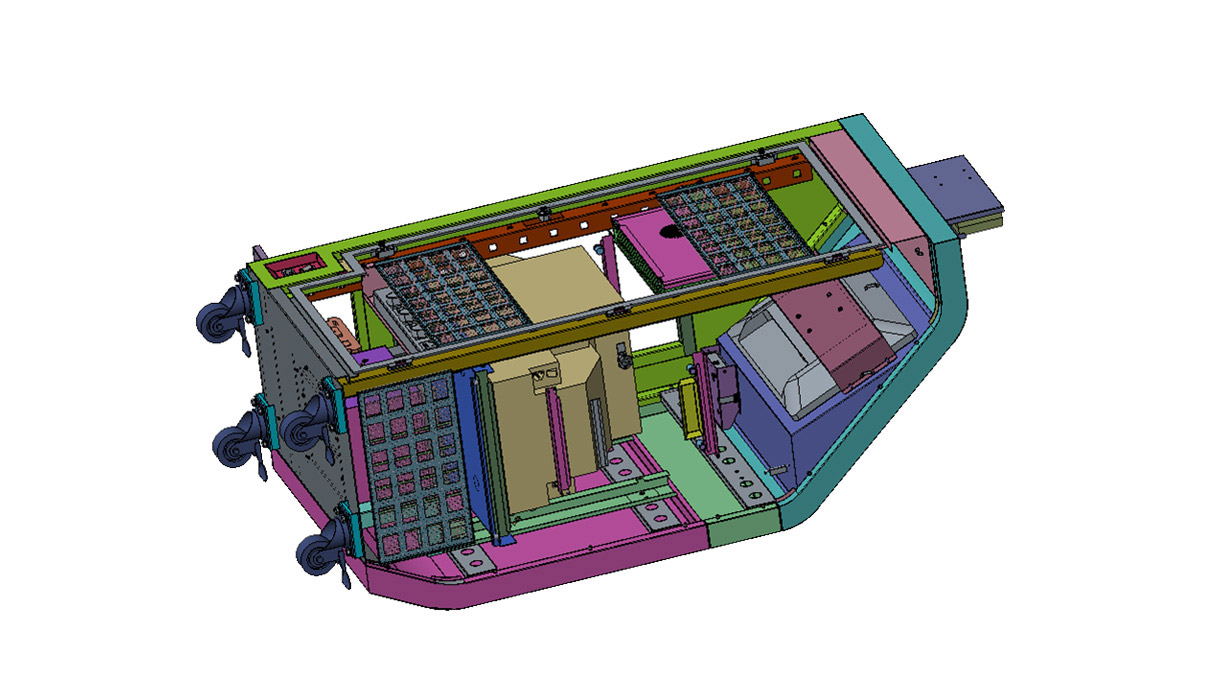

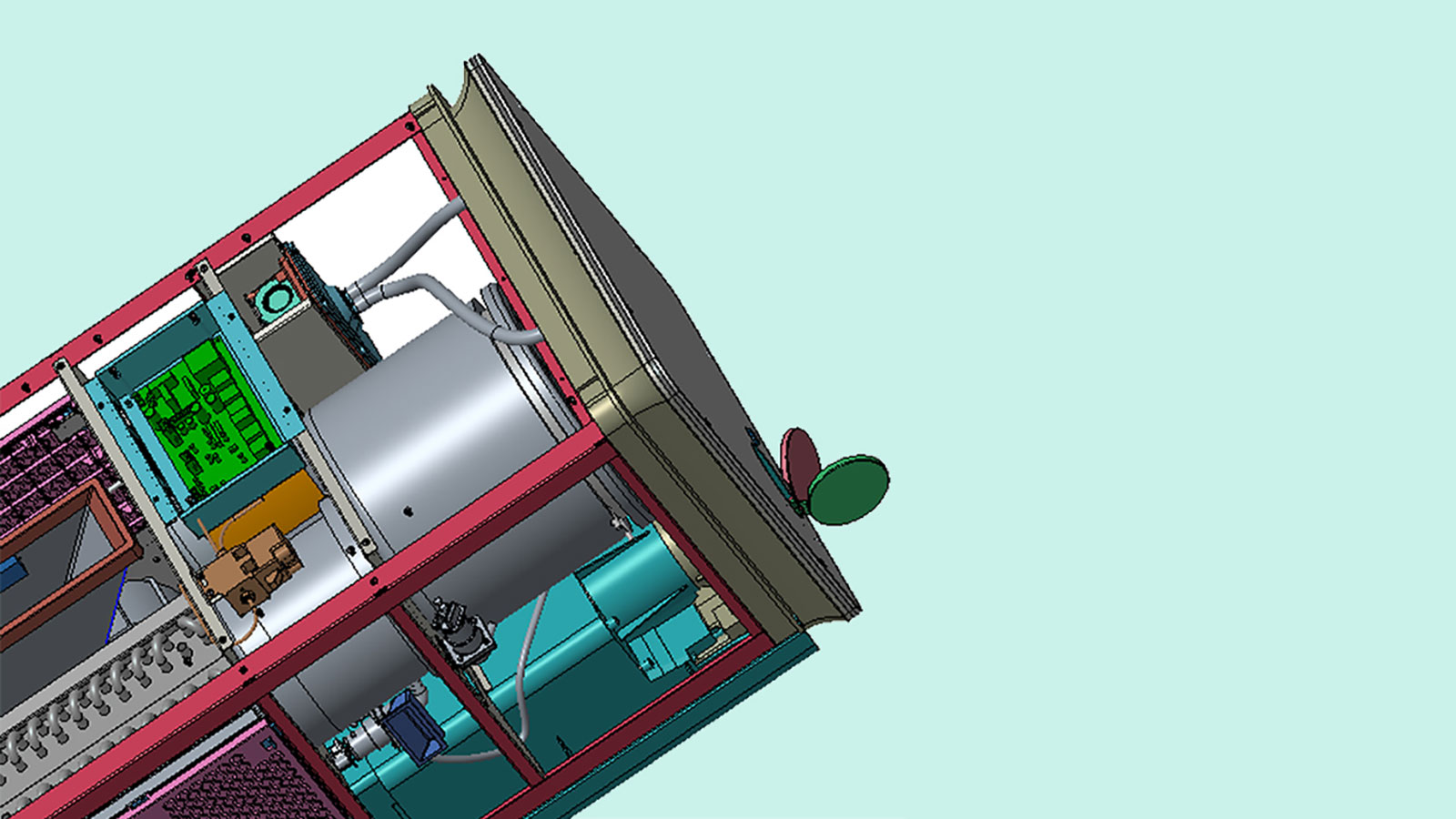

Product structure design is a very complicated work link in the product design process and plays a very important role. Product structure design is the design of the internal structure and mechanical parts of the product, which is directly related to the reliability and practicability of the product, whether the functions are complete, whether the parts can operate normally, and whether the production and manufacturing can be completed. Common product structure design mainly includes sheet metal structure design, plastic product structure design, and electronic equipment machine structure. The design of sheet metal structure mainly includes stretching parts, blanking parts and bending parts. The structural design of the stretched parts, the shape is uniform and symmetrical, the contour changes are soft and smooth, the top flange width is the same, the bottom hole size is appropriate, the overall structure design is reasonable, and the manufacturability is good; the blanking structure design should ensure high material utilization and the number of processes Small, simple mold structure, high life, stable product quality, etc. Precision requirements, geometric shapes and dimensions have the greatest impact on the structure of blanking parts; bending structural design is to make the material produce plastic deformation, forming a certain curvature and angle parts of the stamping process, good process performance to simplify the process, improve the accuracy of bending parts. The structural design of plastic products includes shape, demoulding inclination, reinforcing ribs, signs, bottom bearing surface, rounded corners, holes, patterns and other aspects. Good plastic products are both beautiful and generous, and easy to form. The whole structure of electronic equipment mainly includes the structural form of the chassis, the structural form of the cabinet and the opening form of the ventilation window. Equipment, devices, instruments, meters, etc. made by the principles of electronics are usually collectively referred to as electronic equipment. The structural design of electronic equipment has a unique structural composition. Electronic elements, devices, mechanical parts and components need to be installed inside. Common structures are divided into two types: chassis and cabinet. Product structure design is based on the overall design, according to the determined principle plan, determine and draw a specific structure diagram, reflect the functionality, and specify the abstract working principle to a certain type of component or component, and determine the specific content The material, shape, size, tolerance, heat treatment and surface condition of the structural part also need to consider the processing technology, strength, rigidity, accuracy, and the relationship between parts. Structural design is not a simple mechanical drawing, drawings are only the language to express the design scheme, and the concretization of comprehensive technology is the basic content of structural design. Structural designers should have all-round and multi-objective spatial imagination, and have the ability to coordinate and integrate across fields. Seek unity in opposition according to various requirements and restrictions.

The copyright of this work belongs to 白狐设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

White Fox Industrial Design provides a one-stop management comprehensive service of product design, structural design, appearance design, medical device design, mold design and product production, manufacturing, and supply chain management for users with design needs. It is known as the most knowledgeable manufacturing design company.

Official website link: http://www.bifoxs.com.cn/

Contact: Mr. Wang 18818577695 (same as WeChat)