Vacuum cleaner design

What needs should a vacuum cleaner meet? On the floor, wall or sofa in the home, there are all kinds of hair and dust everywhere. Even if there is a sweeper at home, it is useless. And without a vacuum cleaner that can suck up both hair and dust, the home is like a garbage disposal station. If the house is not cleaned, dust will never have nowhere to go. Cleaning becomes a very headache. Now people pay more and more attention to the quality of life, but the environment is getting worse and worse. We should know that human beings are the largest biological ecosystem in nature. Therefore, how to make the house clean more relaxed and sanitary is one of the issues that people are very concerned about. As one of the commonly used cleaning tools, vacuum cleaner plays a vital and important role in household cleaning. The following is an introduction and design method on how to design a vacuum cleaner product from the use scenario.

1 Design Objectives

This vacuum cleaner product is an intelligent vacuum cleaner. During the working process, the product will automatically sense air humidity, air quality and other parameters, and pour air from the water tank into the corresponding vacuum cleaner according to the set instructions. When in use, the vacuum cleaner will automatically vacuum and generate a large amount of negative pressure when inhaled so that the dust is adsorbed in the air. In this way, when you clean, you don't need to work hard to clean up the dust on the ground. Communicate with users to understand what kind of cleaning tools they need. Understand their requirements for vacuum cleaner products through communication between users. According to the product functions that users may need, such as cleaning function, suction increase and dust collection distance, the product is designed, and the final choice can be obtained by analyzing and comparing these goals. The main functional requirements for vacuum cleaner products are: ① strong cleaning ability; (2) automatic vacuum; (3) prolong the service life; (4) high ease of operation. For the vacuum cleaner product design scheme, it can be seen that it mainly compares the design schemes for these three aspects. According to the needs of users, these three aspects can generally be divided into the following three aspects: ① the product has different functional requirements under different usage scenarios; (2) the requirements of each function under different usage scenarios are different; (3) the functional requirements of products under different usage scenarios are different. Based on the above three aspects, it can be seen that the main functional requirements of vacuum cleaner products are more practical and reasonable and orderly products in the use scenario. The same is true in terms of vacuuming capacity.

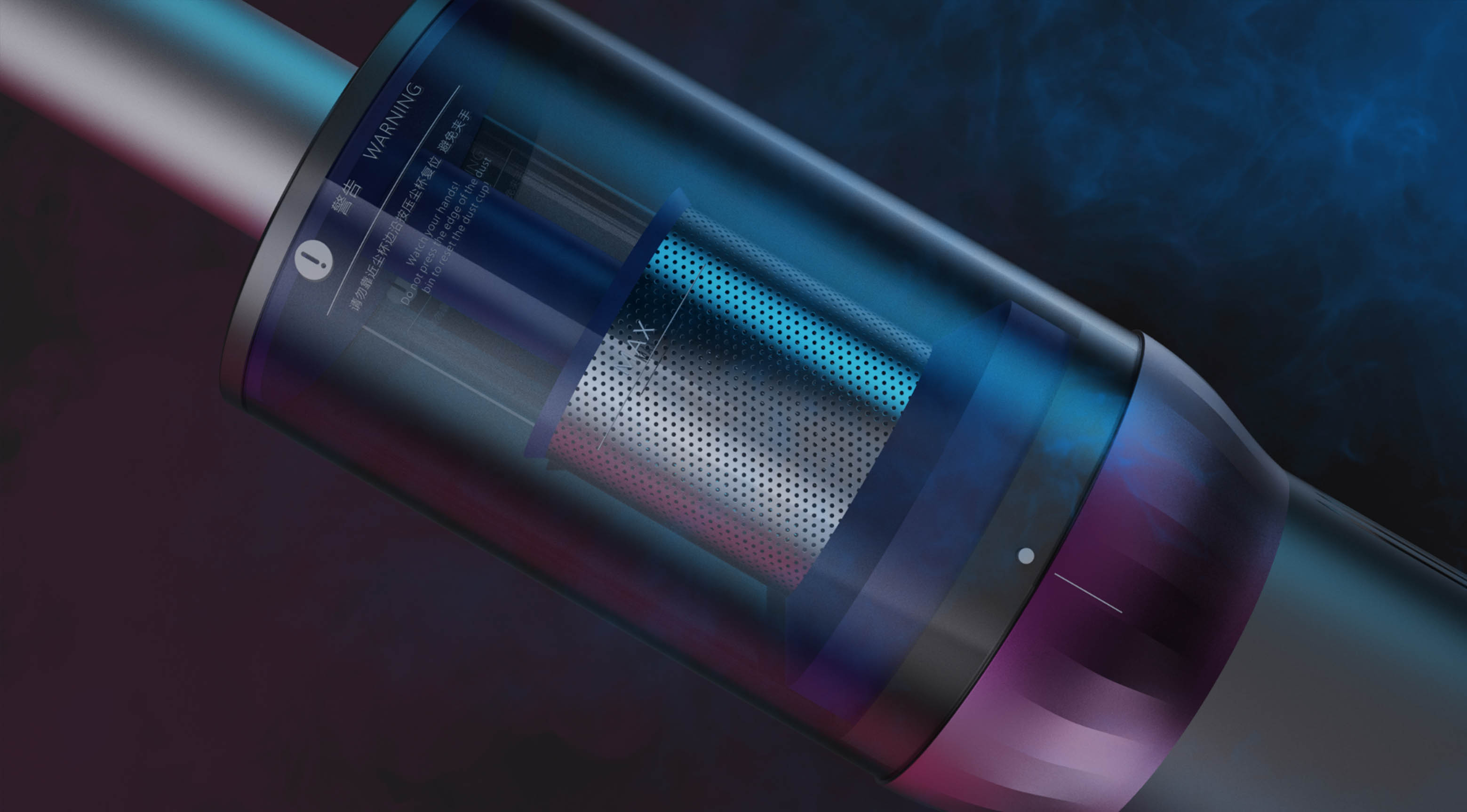

2 Structural principle

The vacuum cleaner is divided into two structures: a vacuum box and a dust bag. The function of the vacuum box is to suck the dust on the ground into the dust bag. The main function of the dust bag is to filter the particles in the air into the dust bag. The dust bag consists of two parts, one is the dust bucket and the other is the filter screen. The dust bucket is divided into two parts: the dust box and the filter screen. The dust box is divided into two forms: detachable and washable. The main function of the filter is to filter and wash dust. The vacuum box can be divided into manual and automatic forms. There are two main forms of manual dust removal box: one is to switch the dust removal box by toggle the handle or automatic gear shifting; the other is an automatic dust removal box controlled by a microcomputer. You can select on/off through the knob. According to the actual use, the number of switches and modes need to be adjusted: in the automatic dust removal box, the manual dust removal box can adjust the number of switches or modes through the knob; In the automatic opening/closing of the dust removal box, the number of switches or modes can be manually controlled through the microcomputer control panel; If a knob is set on the microcomputer control panel, the automatic opening/closing of the dust removal box is the opening/closing of the dust removal box.

3 Product performance indicators

Product performance indicators are the most basic indicators for products to meet the requirements of use, and can reflect different performance indicators under different dust collection modes. According to the above indicators and design requirements, vacuum cleaner products are divided into three categories: suction (TPA), noise (HEPA), endurance (HSE). In each level of product performance indicators can be subdivided into two main aspects: two-in-one motor group, filter (filter element) and charger. The two-in-one motor unit mainly completes the conversion of suction. Starting from the actual usage, the motor group can be selected in the following ways: 1) Choose whether it can be connected to multiple gas circuits according to user needs. 2) According to the actual needs of users, choose whether to quickly change direction and replace the filter. 3) Choose whether it is suitable for maintenance according to the user's personal habits. 3) Analyze whether it is necessary to switch the power control mode (such as switchable mode, energy-saving mode, etc.) according to the usage scenario. According to the user's use scenario, put forward their own requirements for the performance of the vacuum cleaner. For example, when the floor is uneven during the vacuuming process, the vacuuming effect will be poor and the entire vacuuming process will be affected; when the vacuuming is over, it will be found that the dust in the dust collection box is too much and cannot be cleaned, resulting in blockage and the vacuum cleaner cannot be used normally; when the vacuuming is completed, the vacuum cleaner cannot complete the cleaning of the room, etc. According to the above-mentioned user requirements, the problems encountered in the dust collection process, the causes and environmental factors, the performance of the vacuum cleaner is designed and optimized for use.

4 Overall objective

The overall goal of vacuum cleaner products is mainly divided into three parts: one is the appearance design of the product, which determines whether the product can meet people's needs and whether it can be favored by people. The second is functional design. It determines whether the function of the product can meet people's needs. The third is the user experience aspect. There are more and more fully functional smart products on the market, but most of the functions can only be implemented in a single part. The number of functions directly affects the use value of the product. Therefore, the product should be able to meet the use requirements in different scenarios and be able to integrate various functions.

5 Process

Due to the large volume of the vacuum cleaner, the internal structure of the vacuum cleaner should be reasonably arranged in the whole process. First of all, the appearance design should be carried out, and the structure should be simply modified to make the structure more beautiful. For example, some burrs and corners are rounded to contact the vacuum cleaner; at the same time, painting treatment is carried out to make the surface of the fuselage smoother and smoother. Configure several small buttons and detachable hose heads on the product for cleaning or mite removal. The suction nozzle of the vacuum cleaner needs to be designed in a form that will not fall off to prevent the body from being unusable due to wear. Pay attention to prevent air leakage or water leakage when installing the machine, so pay special attention to the suction nozzle during the installation process, and carefully check the vacuum cleaner to ensure that the product quality is not affected. In addition, there must be enough space inside the vacuum cleaner for storing accessories, so the accessories should be placed in sequence during assembly to ensure the overall stability of the product and to ensure sufficient space for disassembly. At present, most of the vacuum cleaner structures are designed with vertical structure, rotating structure or inverted structure. In addition, for a vacuum cleaner, the suction force is generally completed by the buckle and joint and bearing of the soft magnet. For the soft magnetic products of different heights, the motor height may be different, so the corresponding soft magnet is made of different materials to ensure the suction force, which is also a simple and convenient design method.

The copyright of this work belongs to 130****9235. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

It is recommended that when editing a work, shorten the introduction part, or put it into the work picture remarks in sections, and the display effect is better.