Design background:

The project was completed in 2016. It should be a few years from now. At that time, it was required to consider the requirements of cost, durable structure and some continuity with the company's previous products.

Design point analysis:

From a design point of view, an engineering hand-held inspection product should give people a strong and durable emotion, but we all know that the more round the actual contact with people, the better the man-machine, so this product will inevitably have lines of different personalities. How to make these lines of different personalities harmonious requires designers to deal with a design point when designing.

Since there are many product lines in this industry, but the number is not particularly large, how to save mold costs for customers is also a design point for us to deal with this type of equipment design. The processing method when we design is: 1. Common mode processing as much as possible. 2. Can extend different types of interface boards as far as possible to disassemble parts. This is convenient and compatible with non-model products. 3. Distinguish different categories or models of products through color change.

Let's take a look at this design.

The main body shape adopts relatively smooth lines and appropriate straight lines to make the whole product soft and strong, with both affinity and a certain sense of strength. Considering the use environment of the product, the main body is mainly dark and stain-resistant colors, and at the same time matches bright small pieces, which is convenient for users to find the product at a glance in a complex environment.

Considering the large 12-inch screen, in order to ensure the strength of the shell, we adopt the form of disassembly in which the upper and lower shells of the main body are matched with left and right encapsulation, which is also well handled and has a certain continuity with other previous products. The coating adopts a completely symmetrical form, which is convenient for left and right common mode and saves cost.

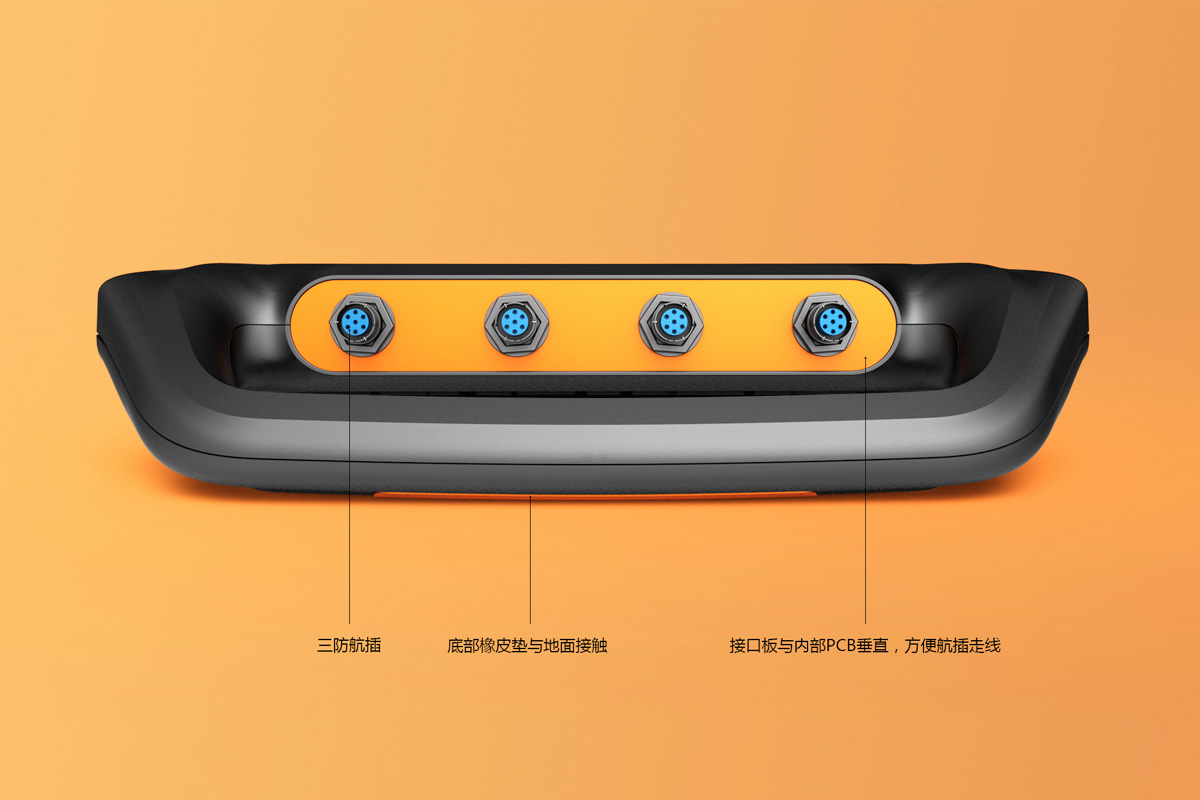

The top interface board (there is also a small interface board on the 2 side with glue). Considering that it is suitable for different types of products and compatible with different channels, we design and disassemble these interface boards into small parts to facilitate mold opening and replacement. In addition, in order to simplify the structure and enhance durability as much as possible, we merge the bracket and handle into one component.

Actual usage scenario

In fact, when designing a project, it is also subject to many restrictions. It is a difficult point that we styling designers often face when balancing various factors as much as possible, especially for newcomers to the design industry. I hope my simple sharing can help you. At the same time, designers are also welcome to discuss and correct them.

The copyright of this work belongs to 做设计的热干面. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

IDC's Big Brother

These designs are all designed by a designer I know. I always think he is a person who feels great in design.

Don't say good or bad, look at the products you make always feel uncomfortable, as if a little too tangled

Stick