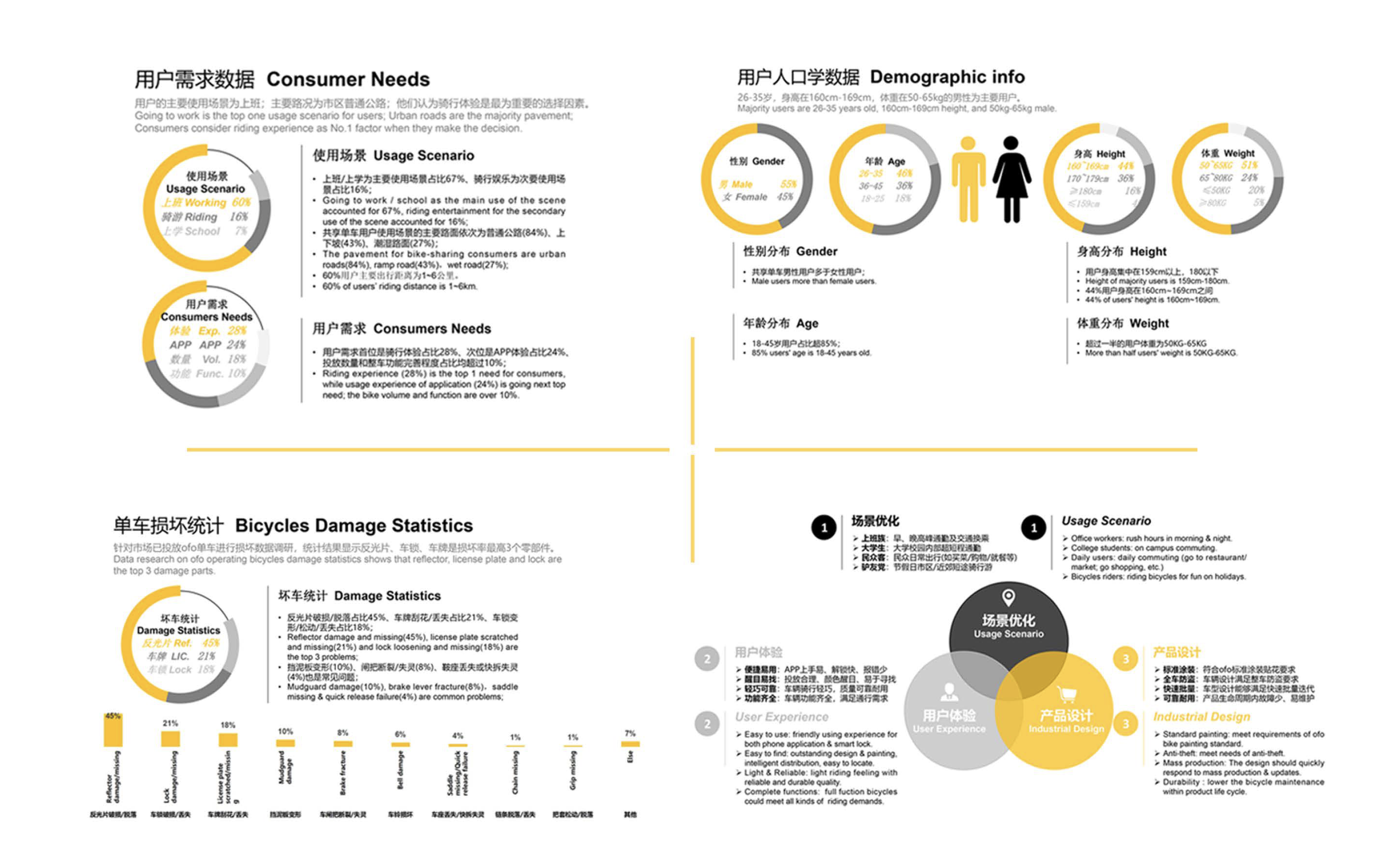

From 2016 to 2017, ofo and flex (Flextronics) jointly developed and designed a 24-inch shared bicycle (to add a historical background, mobike chose to cooperate with Foxconn at that time). Since Flextronics itself is more of a substitute factory for 3C products (similar to Foxconn) and does not have the ability to weld the frame, this time we adopted a new processing method to realize the frame molding-gluing.

This car is almost the most complex and top-notch design in the sharing field, and it is also my last design work in ofo.

The follow-up spring was launched in Zhuhai, Guangzhou, Hong Kong and Singapore.

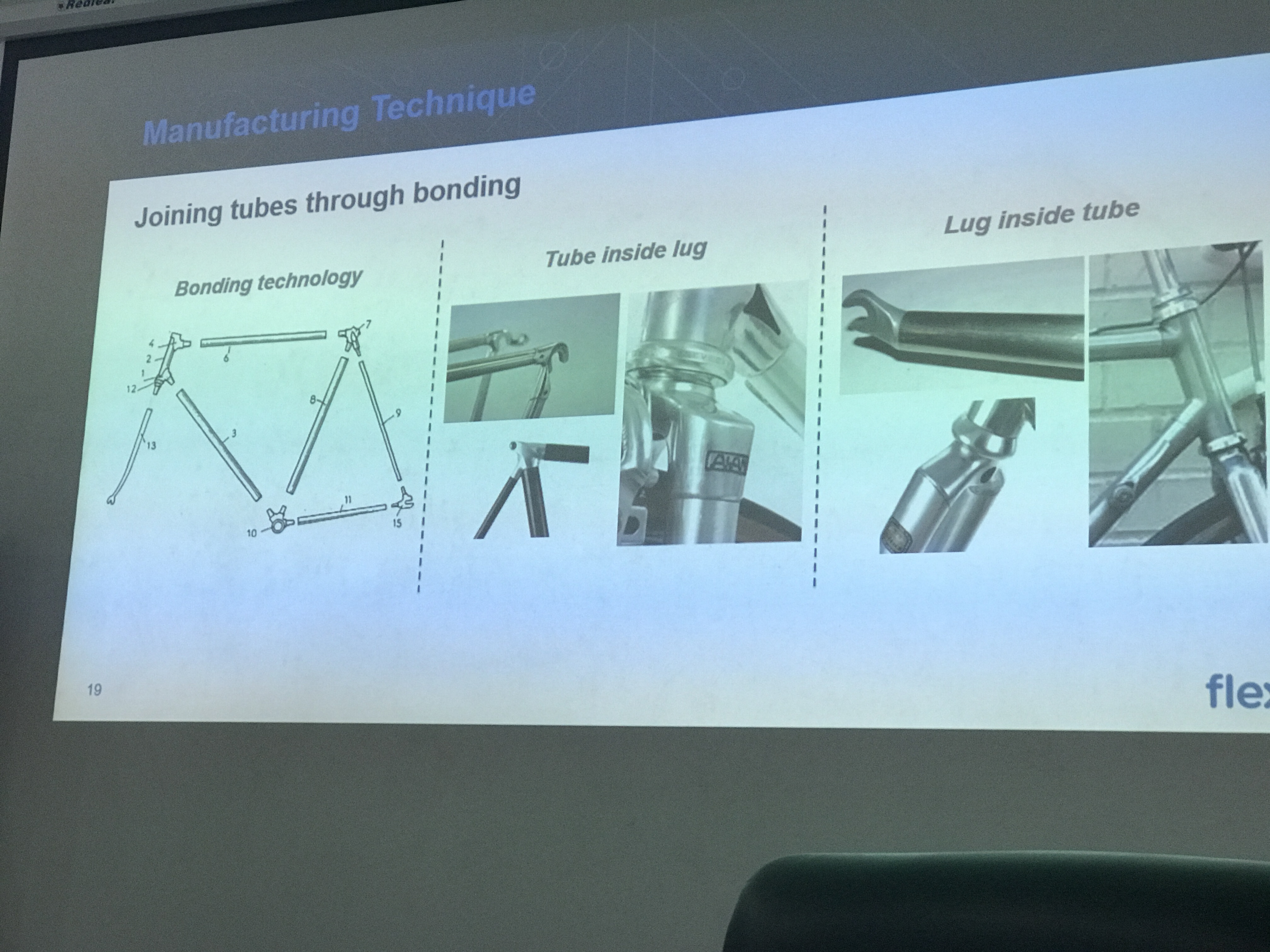

The gluing process has long been used in the bicycle field, such as Japanese city cars or carbon fiber frames, but this process has not been tried in the sharing field. But the main reason is that the traditional bicycle factory has a cheaper welding process, why choose a more expensive one in front of the cost?

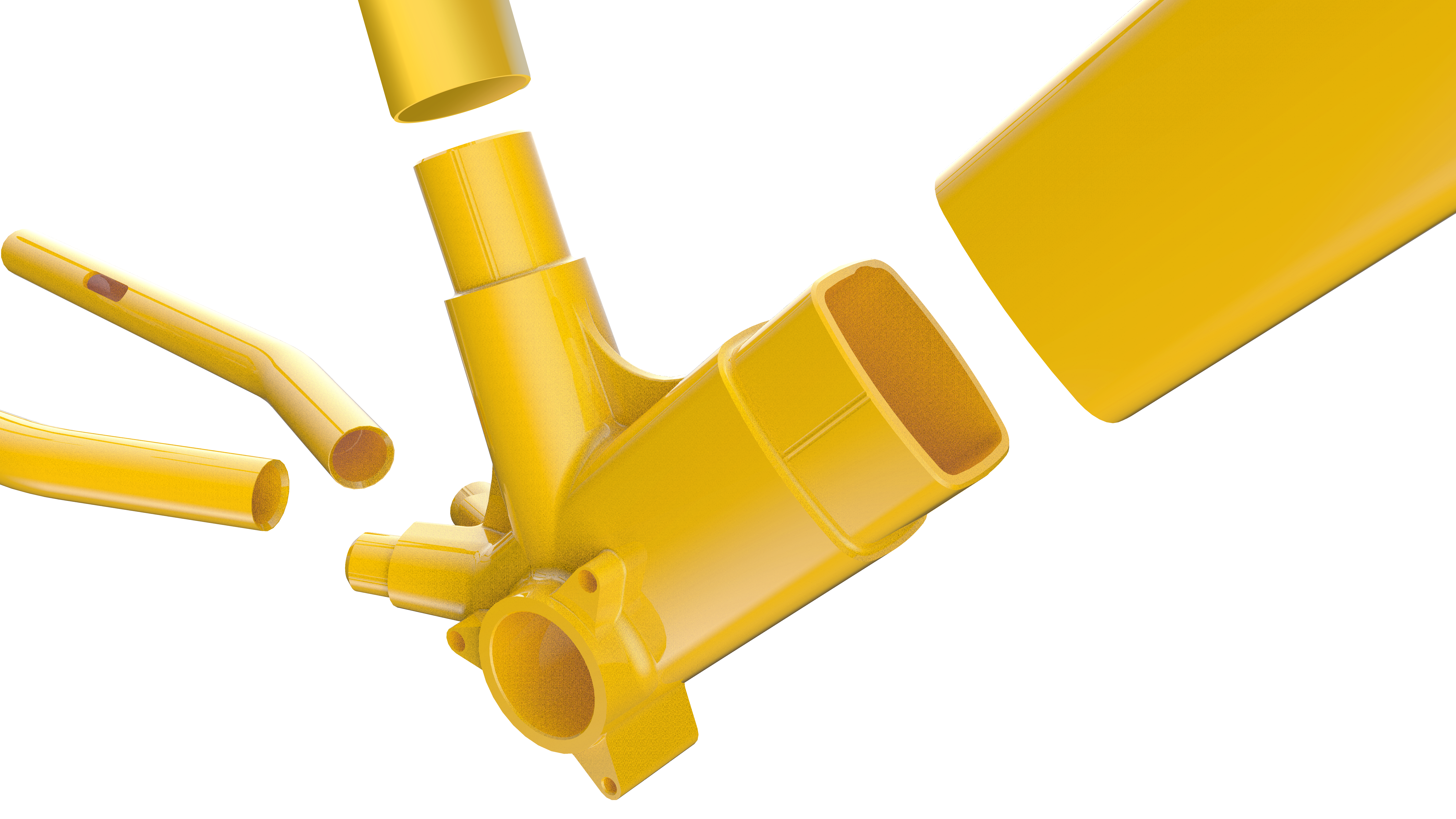

Preliminary verification of appearance structure

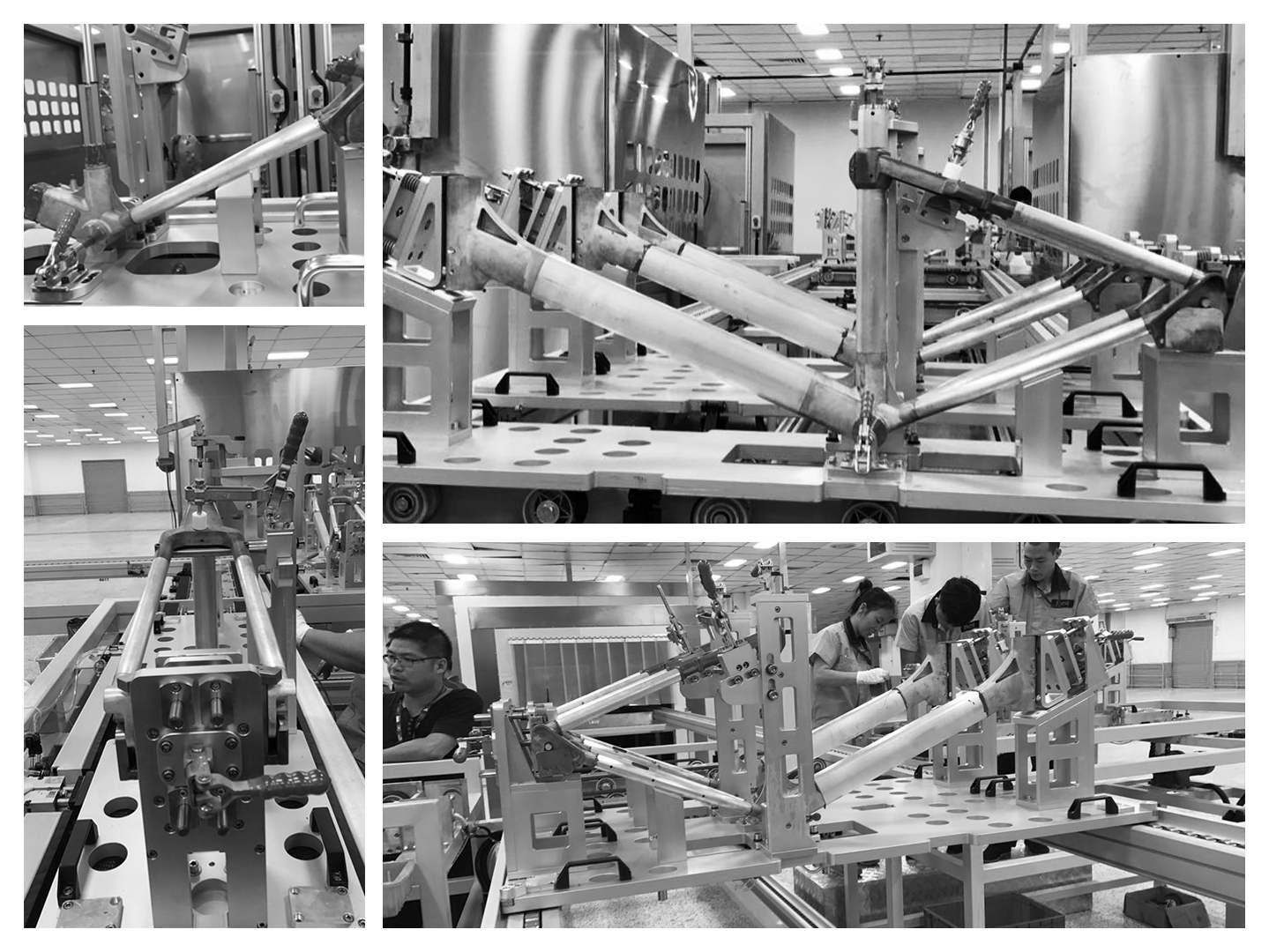

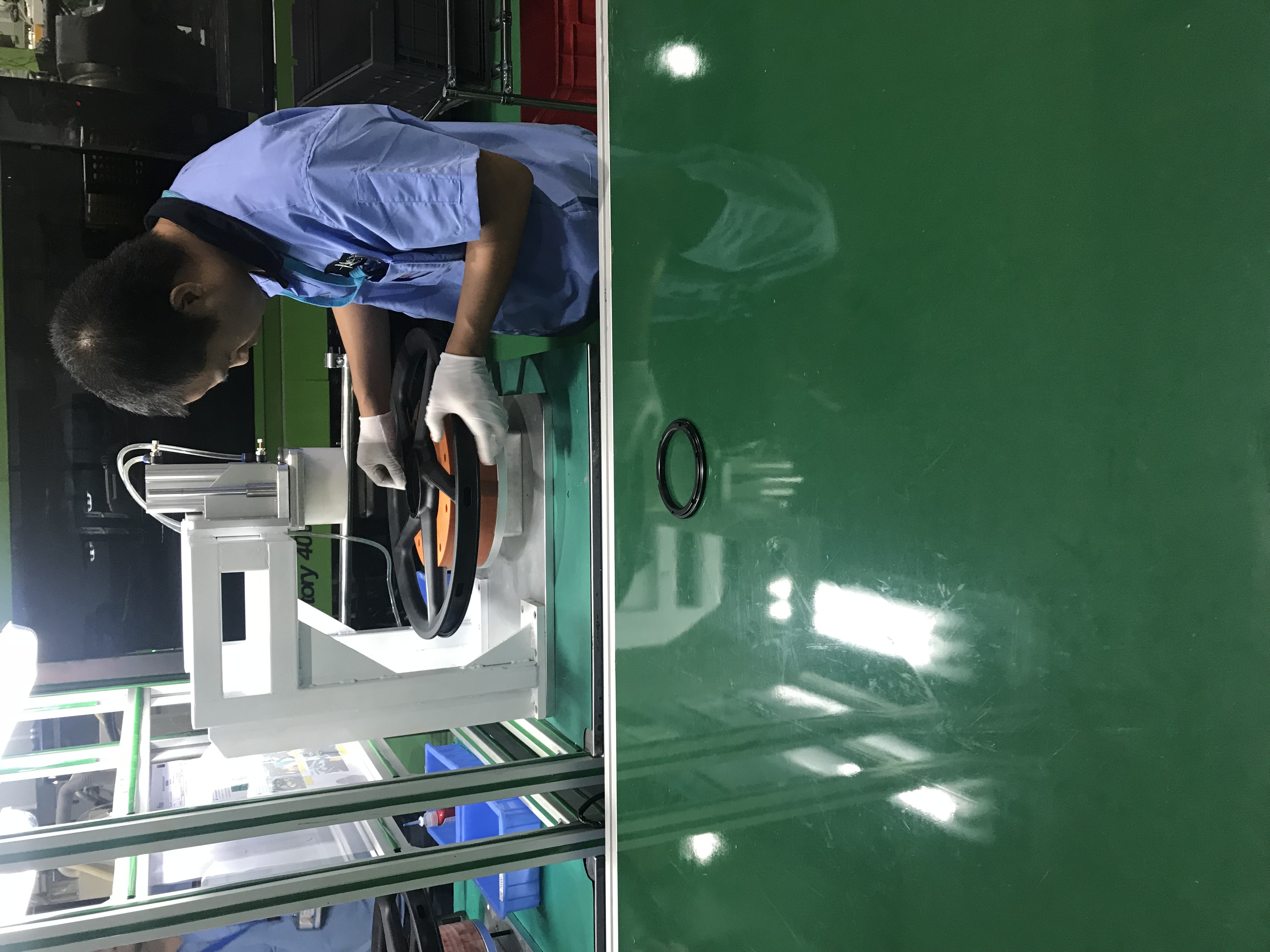

In order to realize the gluing process, a batch of fixtures were designed by Flextronics. After the parts were fixed, they were sent to the oven for heating and curing at 150 degrees twice.

After this set of process tools, the overall tolerance of the frame can reach ± 0.2mm, which is also the top level at the C end.

The glue between the parts is done by the robotic arm

The frame parts are composed of profile castings

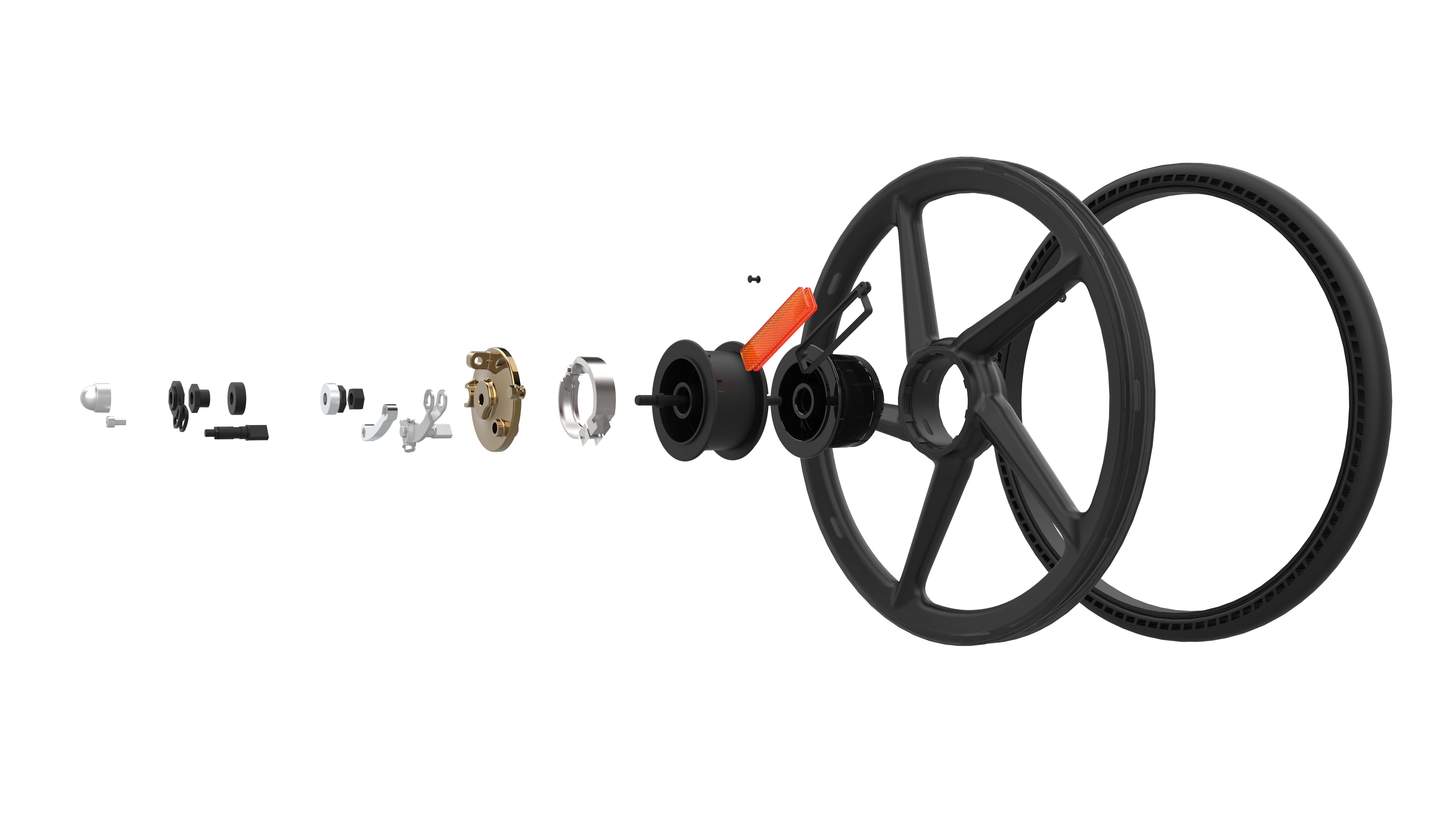

In the design of the wheel set, we also spent a lot of thought, not using aluminum-magnesium alloy, using composite materials.

Tin is used as the inner mold for wheel group injection molding, and pa66 GL is used for injection molding. After molding, it is heated to about 235 again, and tin melts, leaving a cavity.

Fixed makeup effect diagram

Obvious splice can be seen at the splice joint.

The first off-line car, at that time the mold of the vegetable basket was not ready,,,

On the day of offline, flex also specially held a ribbon-cutting ceremony for offline.

Small design for Hong Kong

Photo taken in Singapore

Within a career, this design is very special.

Not only do we need to design the products, but also we need to guide suppliers on how to design and produce shared bicycles. After all, flex has never been in contact with bicycles before. We have known all the components and components of bicycles from scratch, and then produced brand-new spring bicycles. However, flex, as a latecomer in the bicycle field, has a strong industrial engineering capability that other traditional bicycle factories will never be able to do.

The disadvantages of this car are also obvious. After this set of technology and production, the cost is 1200 (excluding smart locks),,,

Finally, are you surprised that ofo has developed and designed its own products....

The copyright of this work belongs to Mry.chen. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

It's up to you.

However, from the design point of view, this is not very difficult (but the painful process is only known to the designer himself). As for the molding process, it is normal to reduce the cost after the design IID! (Since you can achieve the effect at a lower cost, why should you pay a higher price?) However, after reading the comments and the reality, it is a bit like cutting leeks, promoting first, raising funds, engaging in stocks, and so on, starting to run away.

Geneva! Money back!

Discovered today.

If the mass production products can achieve the effect of the renderings, it will be perfect.

Designers are the greatest and most amazing people in the world.

No matter what product you make, the first step is to hire a designer!

However, designers should know how to set the conditions before designing, because once agreed, a soldier can order you.

Don't make this profession only inferior, no rights and interests!

So what is your inner monologue when purchasing such a supplier?

-- let's do whatever the boss says

When to refund the deposit

Can I get my deposit back?

The cost of a bicycle with such a poor riding experience is still 1200. If an ordinary car factory produces one and loses one, it can still make money to run away as a shared bicycle.

When will my deposit of more than 200 yuan be refunded to me?

So why choose such an expensive process? This shape is not much different from welding.

Can they give me 99?

Shared Bicycle

Great.