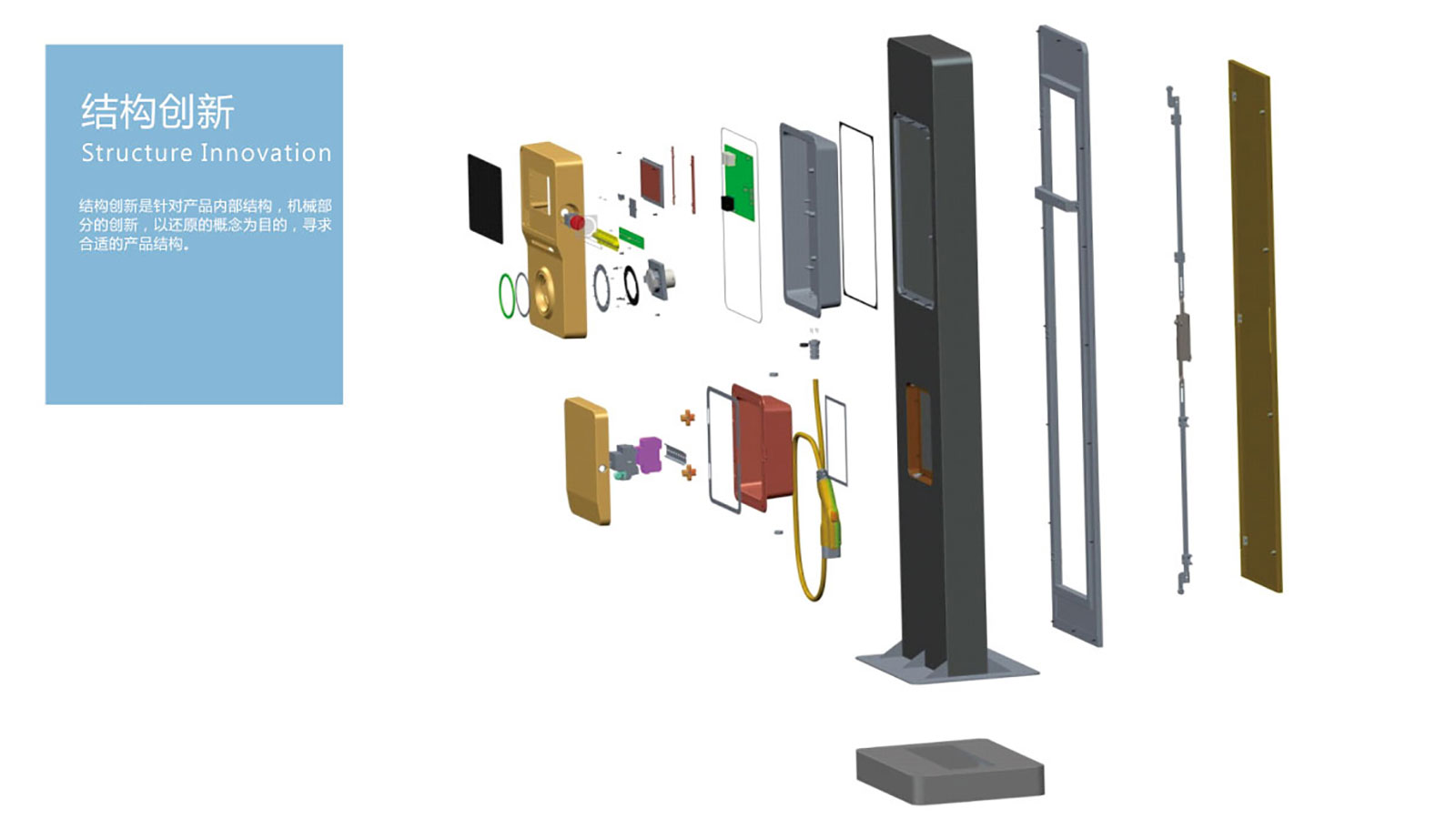

Charging piles are divided into three types: AC charging piles, DC charging piles and AC/DC integrated charging piles according to charging methods. DC charging piles are generally installed in highways, charging stations and other places; AC charging piles are generally installed in residential areas, parking lots, road parking spaces, highway service areas and other locations. Because the charging pile installation environment is different, so in addition to structural design, appearance design, market research, production costs, materials, but also need to fully consider the impact of environmental factors, according to the use of the charging pile environment, the corresponding protection design. The charging pile installation environment is different, and the protection level requirements of the shell are also different. The protection level of indoor enclosure needs to reach IP32; The protection level of outdoor enclosure needs to reach IP54. This charging pile design is mainly used in highways, road parking spaces and other places. The shell is mainly made of sheet metal, and some plastic parts are used. The production process is mature, and the protection level can reach IP54. It has high strength, flame resistance, high temperature resistance, and heat dissipation. Good, rain, sun protection, etc., can meet the environmental requirements of charging piles. In the appearance design of the product, the charging pile design is simple and capable, using a combination of straight and broken lines, interspersed with geometry, and the proportion between the parts is perfectly designed by the designer, simple design techniques and Process processing not only shows the professional design level that the product should have, but also outlines its unique and delicate personality beauty, which is simple and atmospheric. Whether it is indoor or outdoor, the charging pile design must have sufficient strength to protect the internal electrical components from the influence of external impact, and at the same time must have fire prevention, flame retardant, insulation and other properties to ensure the safety of electricity. The circuit boards, connectors and other circuits in the protection charger shall be treated with moisture-proof, mildew-proof and salt spray prevention, so that the charger can operate normally in outdoor humid and salt spray environment with anti-rust (anti-oxidation) protection. Charging pile shell and exposed to the outside of the iron bracket, parts should take double anti-rust measures, non-iron metal shell should also have anti-oxidation protective film or anti-oxidation treatment, etc., in order to improve the environmental reliability of the charging pile shell.

The copyright of this work belongs to 白狐设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

White Fox Industrial Design provides a one-stop management comprehensive service of product design, structural design, appearance design, medical device design, mold design and product production, manufacturing, and supply chain management for users with design needs. It is known as the most knowledgeable manufacturing design company.

Official website link: http://www.bifoxs.com.cn/

Contact: Mr. Wang 18818577695 (same as WeChat)