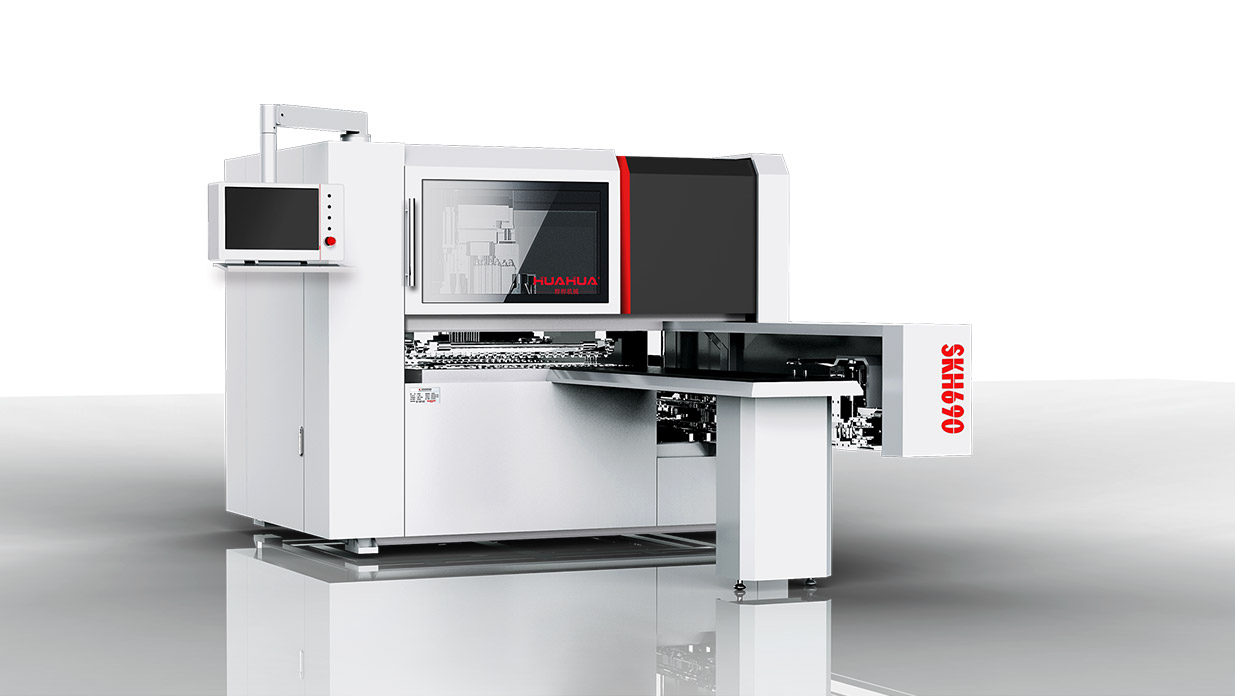

Six-sided drilling and milling machine is also referred to as six-sided drilling, which belongs to CNC drilling and milling equipment and is suitable for customized panel furniture production and processing. Six-sided drilling and milling machine is a professional equipment used for drilling, slotting and milling. It can complete the processing of six-sided holes at one time, and side drilling can automatically process four-sided side holes horizontally. The vertical saw of the saw bag on the plane drilling and the saw bag under the saw bag automatically processes the vertical holes on the top surface and the bottom surface respectively. The six-sided drilling and milling machine replaces the traditional multi-row drill, CNC side hole machine and five-sided drill, with complete functions, efficient processing, high accuracy, and simple and convenient operation. Not only reduces the intensity of manual work but also improves work efficiency. The design bed of the six-sided drill and washing machine includes a lower guide rail seat, an upper guide rail seat, a rear column, a front column and a bed door panel. The upper guide rail seat is directly above the lower guide rail seat, the rear column is connected and supported between the rear end of the lower guide rail seat and the rear end of the upper guide rail seat, and the front column is connected and supported between the front end of the lower guide rail seat and the front end of the upper guide rail seat; The door panel of the bed body is arranged on the front side of the front column; Both the lower guide rail seat and the upper guide rail, the two screw servo drives are facing each other up and down. Using a new generation of digital control system, it can be perfectly connected with production management software. The system integrates CAM software, which can edit and generate processing programs for sheet metal graphics, support barcode scanning, automatically load processing graphics files and generate tools, stable and reliable performance, The operation is very simple and convenient. The visual window design is convenient for equipment maintenance. The double manipulators of the six-sided drilling and milling machine automatically clamp the plates and send them to the machine for internal processing to improve the processing efficiency. Automatically detect the relevant dimensions of the plate to prevent manual errors; Automatically record all kinds of information to facilitate production management; Open software docking interface, compatible with various docking formats; The worktable is filled with pneumatic floating beads, so it is easy to move the plate on the worktable to prevent scratching the plate. Special-shaped processing, automatic slotting, cutting and modeling functions according to slot information; The automatic pressing anti-springboard device can automatically lean on its side and automatically lean on the side of the plate according to the size of the plate to detect the width of the plate and prevent misplacement of the plate. The discharge automatically sends the plate to the rear discharge configuration, and the process is set up perfectly. It is also equipped with an automatic oil filling lubrication system to inject lubricating oil in time to ensure the normal operation of the machine.

The copyright of this work belongs to 白狐设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

White Fox Industrial Design provides a one-stop management comprehensive service of product design, structural design, appearance design, medical device design, mold design and product production, manufacturing, and supply chain management for users with design needs. It is known as the most knowledgeable manufacturing design company.

Official website link: http://www.bifoxs.com.cn/

Contact: Mr. Wang 18818577695 (same as WeChat)

Can

Not bad