Most of the companies that produce precision cutting saws in China start the design of precision cutting saws from surveying and mapping foreign prototypes, and then improve them according to the problems in their use. Some stress relationships are not thoroughly understood and there is blindness. In view of this problem, in order to meet a certain precision and convenient operation, it is necessary to design an economical cutting saw.

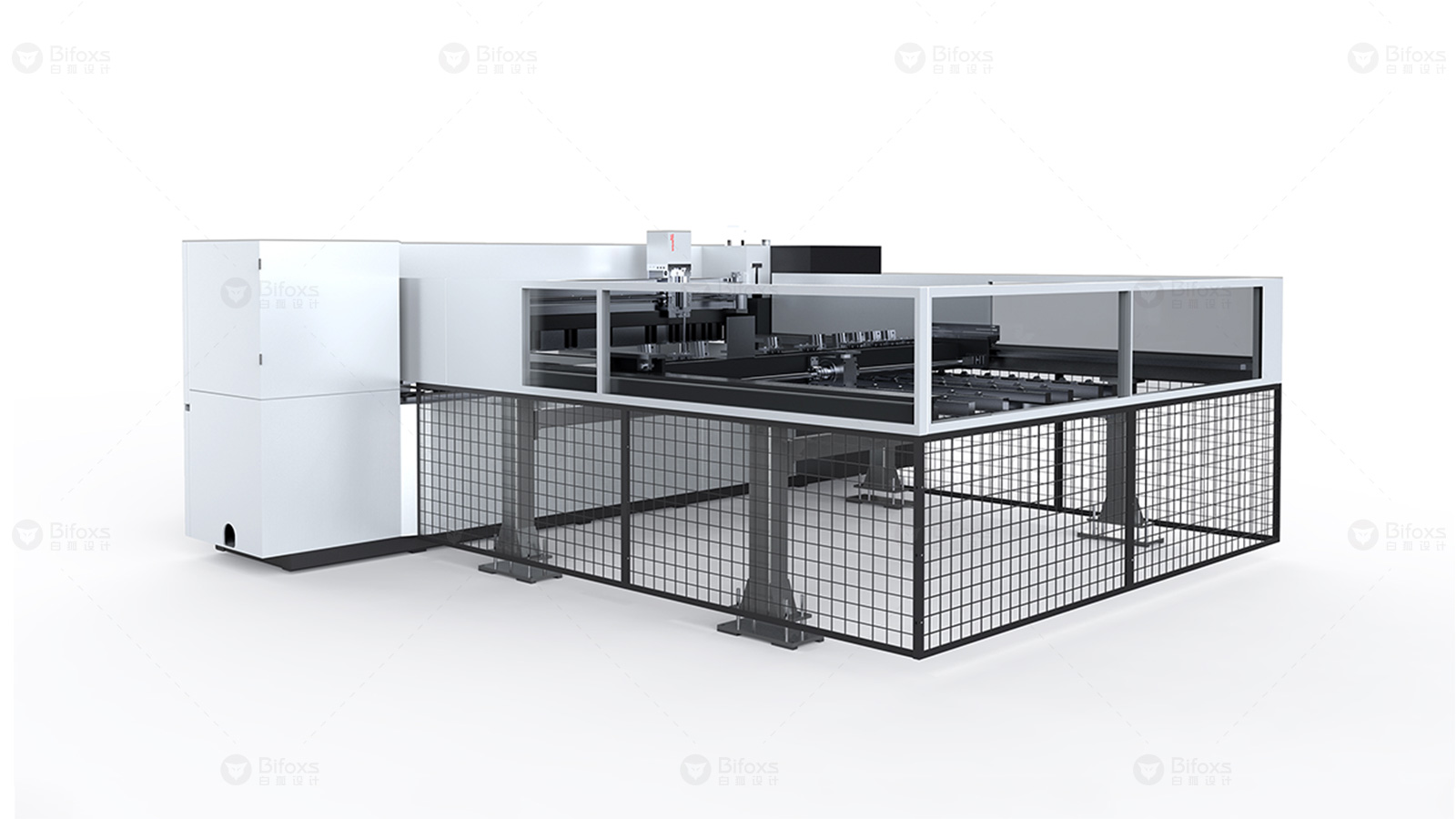

The advantages of this cutting saw design are high operating efficiency of the machine, automatic feeding of material clamping by the manipulator, and the operator can input data on the touch screen to start the machine. Workers do not need to shuttle back and forth between machine parts, and the safety factor is very high. Basically, there is no safety accident.

The board saw designer is equipped with a square linear precision guide rail. The saw car runs smoothly on the precision guide rail, and the saw seat automatically moves forward and backward to complete the cutting. The machine is also equipped with an electromagnetic measuring system, an electronic ruler and an AC motor servo system to perform precision positioning and precision compensation, and the sawing error is very low.

On the basis of theoretical basis, high-level precision cutting saw is designed and manufactured. The structural feature is that the scribing saw blade and the main saw blade do not move, and the moving worktable made of aluminum profiles loaded with processed plates is pushed by hand to move back and forth to realize sawing processing. Due to the special structure of the guide rail of the mobile worktable, it is light and labor-saving when manually pushing the feed, and the processing accuracy is very high.

According to experience, the design problems of cutting saw need to be solved as follows:

1. The reciprocating sawing of double saw blades adopts the structure of positive and negative double saw blades, which can eliminate the cracking phenomenon of sawing panel, and does not need to be trimmed through other processes.

2. Clean working environment The key-type dust curtain can make the working environment cleaner and have higher sawing accuracy.

3. Safe and reliable positioning equipped with cylinder and baffle positioning are selected and used according to actual needs; The telescopic guide makes the sawing of the workpiece more accurate and saves working space.

4. Precision saw seat with fast stroke. The saw seat of this machine is actuated by feed cable, and the sliding is smooth and stable. The stroke device has a buffer cylinder to prevent shock, and the saw seat is extremely convenient to adjust left and right. Cutting performance is high, no burrs are generated, and can be adjusted up and down for sawing depth control, saw blade grinding is time-consuming, and compensation can be adjusted.

5. The longitudinal saw has excellent precision. The saw seat pulley is precisely machined with high-grade copper wheels to ensure fine cutting surface. The surface of the guide rod is plated with abrasion resistance. The support is stable and the longitudinal saw is accurate. The saw seat automatically advances and retreats and is very accurate, with very high efficiency, and can accurately saw a variety of materials (straightness error ± 0.1mm).

6. The pressing cylinder at the front and rear ends of the pressing beam with uniform pressure is designed for synchronous action, and the plate stress is evenly distributed. The cylinder pressure beam is compressed (multiple plates can be overlapped and cut together), and the maximum cutting can be a total thickness of 75mm.

7, efficient work activity type tailgate, so that the wood surprised out of unimpeded. The width of the sawing plate has automatic induction, and the sawing car will return automatically after sawing, which is convenient and fast.

8. In case of careful safety and defense, press the emergency button or when your hand leans into the sawing road, the machine will stop immediately. When the sawing cover of the main machine is opened, the machine will stop immediately. At this time, the saw blade will drop, the pressing beam will rise, and the workpiece will automatically release. Customers can also install infrared probes on both sides of the dust curtain according to actual requirements.

9, no level speed control touch screen control (optional) or key board control, sawing speed with frequency converter speed control, customers can according to the sawing requirements of different materials, no level adjustment sawing speed.

10. Easily move the workpiece (optional) air-floating worktable to make the workpiece move easier and better protect the workpiece from scratches caused by movement.

The design of cutting saw belongs to the design of machine tools. Today's environment requires us to use cutting saw to save time and cost. Therefore, when looking for a design company to design, we must consider accuracy and safety.

The copyright of this work belongs to 白狐设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Comment Board (0)

Empty comment