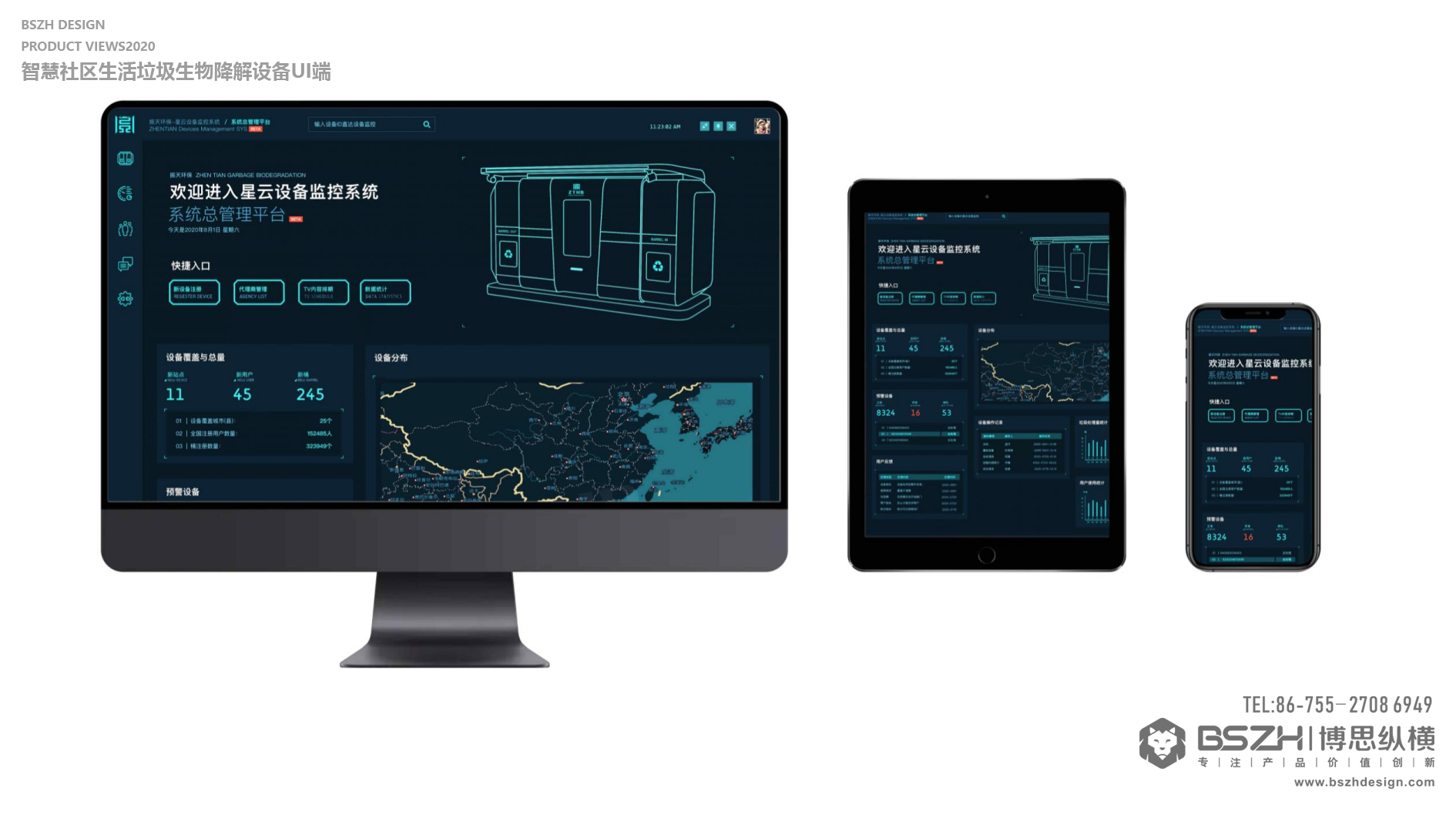

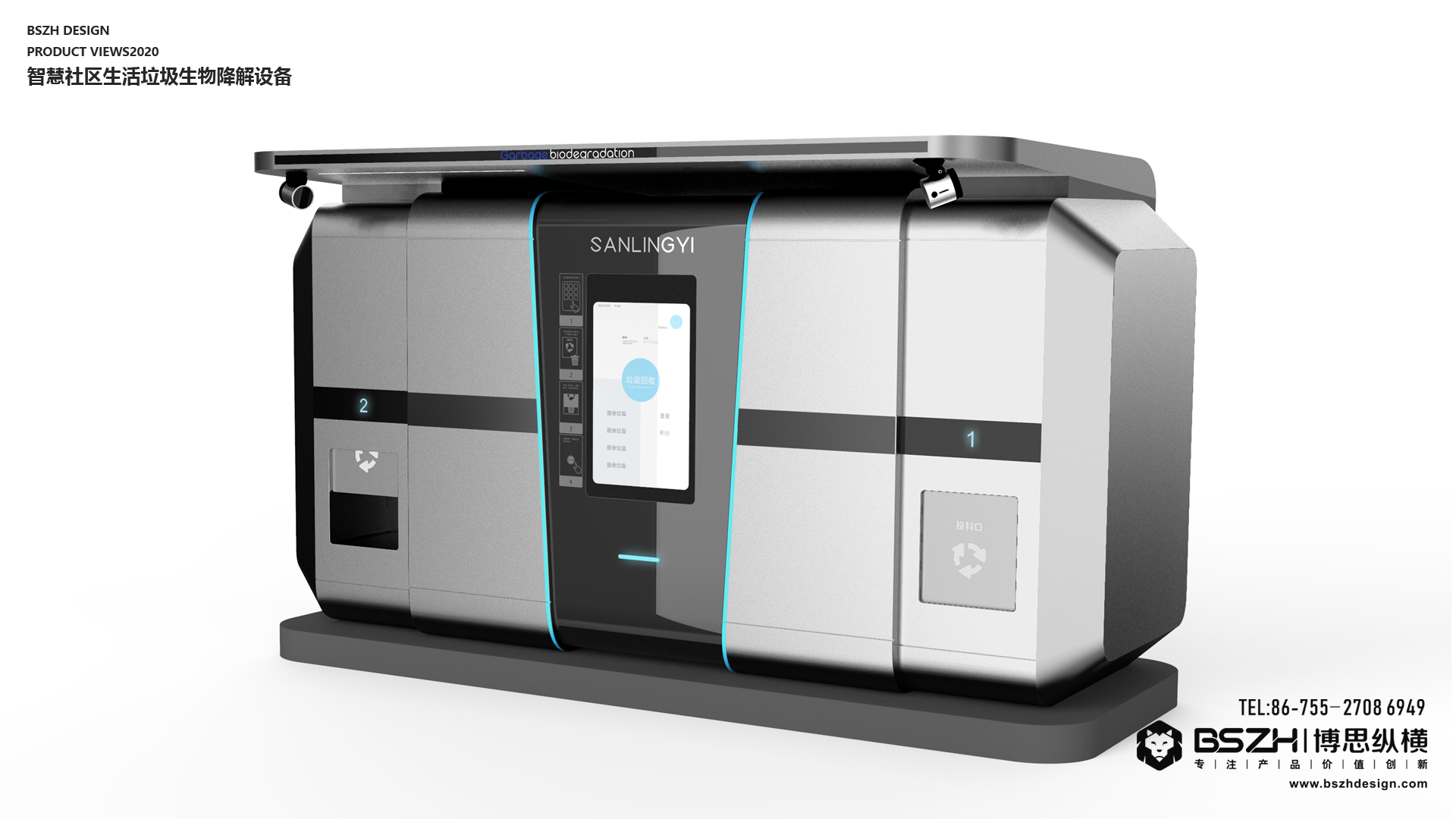

Zhentian Bioenvironmental Protection | Smart Community Domestic Waste Biodegradation Equipment

High-end Industrial Design & Intelligent Hardware Product Design Specialist

Service content: industrial design, product design, appearance design, structural design

With the continuous strengthening of the awareness of garbage classification, the amount of kitchen waste generated far exceeds the processing capacity. The construction of traditional large-scale centralized disposal plants not only faces problems such as difficult site selection and long construction cycle, but also the collection and transportation links are often very easy to cause along the way. Secondary pollution. In order to reduce the utilization rate of plastic bags, the "Smart Community Kitchen Waste Biodegradation Equipment" provides each household with an exclusive kitchen waste trash can, and each kitchen waste trash can also has a unique barcode. As long as the user is at the feeding port in front of the equipment, our equipment will automatically scan the two-dimensional code on the barrel, and the feeding port will be opened inductively after the scanning is successful. The user only needs to put the kitchen waste bin on the pop-up tray, and our equipment will automatically dump the garbage in the kitchen waste bin into the equipment warehouse. After dumping, the barrel body will be cleaned and returned to the user at the same time. The whole process only takes about 20 seconds. Our company independently developed the core patented technology of "high-temperature rapid aerobic digestion", which can efficiently decompose organic wastes such as food and kitchen waste in 0.5-4 hours at high temperature and completely degrade them into carbon dioxide and water (steam) by screening high-temperature compound microbial strains with strong natural life and reproductive ability, with a reduction rate of more than 95%. This scheme can also realize the end-user management of self-information through mobile phone APP and small programs, establish a complete closed loop of online supervision equipment for enterprises, institutions, government agencies, etc., and operate an integral system, which is conducive to improving residents' awareness of garbage classification and mobilizing residents' enthusiasm to participate in garbage classification. At the source of the community, the amount of garbage is reduced, which reduces the great pressure for the government's urban garbage centralized treatment institutions, allows residents to effectively invest in the work of garbage classification, and provides a new solution for the government to build a waste-free city.

The copyright of this work belongs to 博思纵横咨询设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Last year, Bi set up to do this, to consider a lot of things, how to filter out non-degradable food, how to add supplementary liquid, how to deal with waste, the processing capacity of a piece of equipment, how to put it in, how to persuade residents to use it, as well as the operating cost of the whole process, how to make profits, etc,, looking forward to the following works

The design is innovative, but of little practical value. First of all, the amount of such products will not be very large, only sheet metal processing. For large-volume chassis, it is not advisable to have too many irregular shapes. The side enclosure is difficult to process. If it is welded to the chassis as a whole, it will be seriously deformed after one round of welding. If it is a segmented structure and fastened with screws, the error requirement is very high, otherwise the joint will be uneven, and the sheet metal is difficult to ensure this accuracy. Judging from the painting, the color of this enclosure is different from that of the chassis. This one must be separated. It must be sprayed separately and cannot be welded. The large rounded corners of the chassis can be handled well if the mold is opened, and if it is cut across the board, the deformation is very large, and the orthopedic workload in the later period is very large. Moreover, the diagonal line in the middle is divided, which is also very difficult to align. The design of the luminous light bar is a joke. How can it be installed? Originally, the fitting of the diagonal line structure is very difficult to ensure the accuracy. With the addition of a luminous light bar, the structure will be very complicated and the cost will be extremely high.

Is this equipment expensive?

The idea is good

Suitable for high-grade residential area

looks good