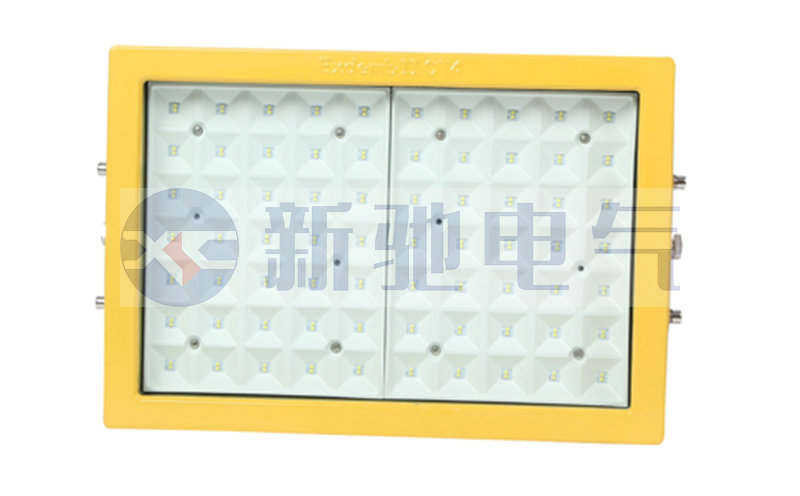

Wuhan supplies CCD97-300W LED explosion-proof floodlights;

Product advantages:

185-265V AC and 24V DC respectively have two power supply modes.

2 The LED integrated module is used as the light source, which has low energy consumption and high luminous efficiency. It is more energy-saving than high-pressure sodium lamp, mercury lamp and metal halide lamp under the same brightness.

3 LED light source for low voltage DC work, no ballast, DC drive power supply and LED light source integrated in the lamp.

Technical parameters;

Manufacturer: Hubei Xinchi Electric

Origin: Huangshi, Hubei

Customization: Yes

Brand: Xinchi Electric

Model: CCD97

Type: LED flood light, LED flood light, LED explosion-proof light, LED explosion-proof lighting

Protection grade: IP66

Light source type: LED

Light source power: 20(W)-300(W)

Main scope of application:

It is suitable for the working environment of electric power, metallurgy, shipping, transportation facilities and other industries. The NFC9173 is suitable for warehouses, ships, trains and other large facilities.

1. general requirements

1. First of all, carefully check and confirm that the explosion-proof lamps have complete accessories, no deformation and other damages before installation;

2. Confirm the specification (cross section) of the wire according to the purpose of the lamp and the installation location;

3. If explosion-proof lamps are to be installed on ordinary brick walls, expansion bolts and fixing plugs should be installed in advance. Qisheng Electric specially reminds everyone not to use wooden wedges to assist installation;

4. We should also pay attention to the installation height of explosion-proof lamps:

A, in the place where there are more risk factors to install lamps should be higher than 2.4 meters;

B, outdoor explosion-proof lamp installation should be higher than 3 meters;

C, lamps installed on the wall should be higher than 2.5 meters.

2. screw explosion-proof lamp wiring

1. For this type of explosion-proof lamp, the phase line must be connected to the central contact (the zero line is connected to the threaded terminal);

2. Attention should be paid to the insulation parts of the lamp shell when wiring (no damage);

3. If the lamp is equipped with a switch, it is necessary to pay attention to the fact that there is no wired head on the switch handle, and pay attention to the distance between the lamp and the insulation should be greater than 5mm (heat insulation measures should be taken if it is less than 5mm).

Installation and maintenance:

1. When leaving the factory, the cable has been connected and the inner sealing ring has been reliably pressed. Users should try their best to use the cable equipped with lamps and lamps to connect to the power supply through the junction box or ballast;

2. The outer sealing ring of the introduction device shall ensure reliable pressing and clamping of the cable;

3. Before the lamp is put into use, the internal and external grounding must be firmly and reliably connected to the user's on-site grounding system;

4. When installing and maintaining lamps, open the lamp shell with electric eyes;

5, stare check the sealing ring, if found its aging should be replaced in time.

The copyright of this work belongs to 防爆灯13972766711. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Good design

Not bad