The product structure design involved in product design is mainly the external shell structure design of the product. At present, the shell material is mainly metal material formed by sheet metal stamping process and plastic formed by injection molding process. The structural design of common products mainly includes the design of sheet metal structure, the structural design of plastic products, and the overall structure of electronic equipment.

The design of sheet metal structure mainly includes the structural design of deep drawing parts, blanking parts and bending parts. The structure design of the drawing parts should be uniform and symmetrical in appearance, soft and smooth in contour change, consistent in the width of the top flange, appropriate in the size of the bottom hole, reasonable in overall structural design and good in manufacturability. The structural design of blanking parts refers to the adaptability of blanking parts to the blanking process. A good blanking structure design should ensure high material utilization rate, small number of processes, simple mold structure and high service life, stable product quality, etc. In general, the accuracy requirements and geometric shapes and dimensions have the greatest impact on the structure of blanking parts. Bending is a stamping process that makes the material produce plastic deformation and forms a certain curvature and angle parts. Bending parts with good manufacturability can simplify the bending process and improve the accuracy of bending parts.

The structural design of plastic products includes shape, wall thickness, demoulding inclination, reinforcing ribs, signs, bottom support surface, rounded corners, holes, patterns and other aspects. Good plastic products should be beautiful, easy to use, and easy to form.

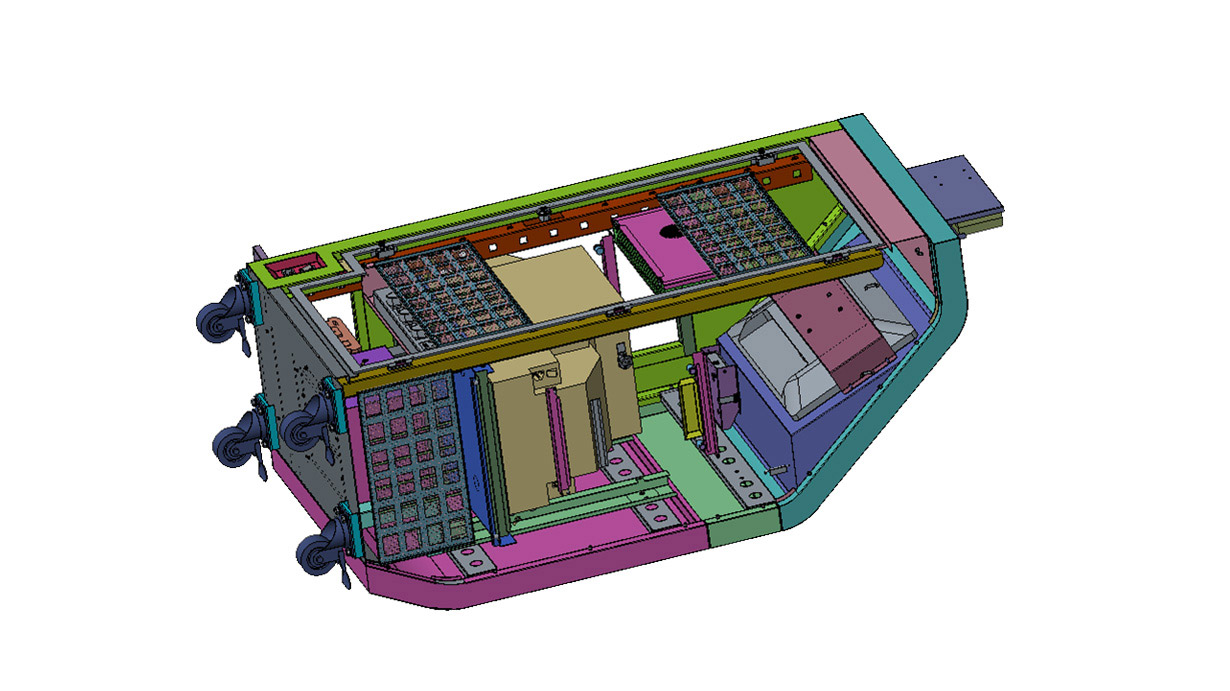

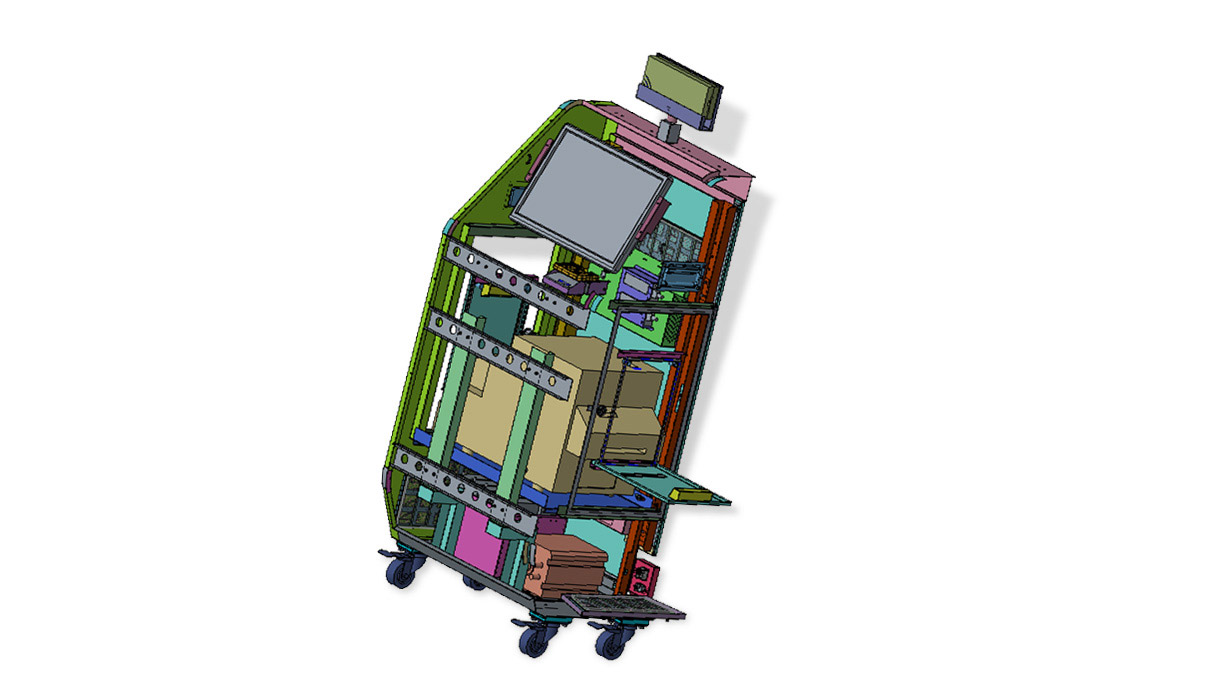

The whole structure of electronic equipment mainly includes the structural form of the chassis, the structural form of the cabinet and the opening form of the ventilation window. Usually, people refer to equipment, devices, instruments, meters, etc. made by the principles of electronics as electronic equipment. The structural design of electronic equipment has its unique structural composition. It needs to install electronic elements, devices, mechanical parts and components inside. Common structures are divided into two types: chassis and cabinet.

To put it simply, the task of product structure design is to determine and draw a specific structure diagram based on the overall design and according to the determined principle plan to reflect the required function. It is to implement the abstract working principle into a certain type of component or component. The specific content is while determining the material, shape, size, tolerance, heat treatment and surface condition of the structural part, it is also necessary to consider its processing technology, strength, rigidity, accuracy and the relationship with other parts. However, the work of structural design is not a simple mechanical drawing. Drawings are only the language to express the design scheme. The concretization of comprehensive technology is the basic content of structural design.

In product research and development, structural design is very important. It involves the stability of product performance, the realization of functions, production technology and other aspects. Whether the structural design can be scientific and reasonable is directly related to the success or failure of product research and development. However, structural design is not a simple job. It not only involves the knowledge of appearance, hand board production, two-dimensional drawing, understanding of materials, safety regulations, mold testing, mold following, machine assembly, testing, trial production, etc., but also has a holistic understanding of stable product performance and functional experience. It is necessary to grasp some key points from the general direction.

Whether the product function can be realized. Structural design is to make a scientific and reasonable layout of the internal parts of the product to ensure the perfect realization of the expected functions of the product. This requires not only an in-depth understanding of the internal parts of the product, but also a certain understanding of the functional operation principle of the product, comprehensive consideration of the operational friction between the parts, optimization of their configuration, and overall design.

Products need to have good heat dissipation, which is mainly for power equipment. Product structure design needs to focus on the performance characteristics of the product, different products, the focus of the structural design is also different. Some products do not need to consider the heat dissipation of the product, only need to consider its stability, such as chairs, wardrobes, tables, etc. However, some products should consider not only their heat dissipation but also their structural stability, such as mobile phones, televisions, computers, airplanes, automobiles and other equipment. Furthermore, this also needs to focus on the heat dissipation of the material of the product. The heat dissipation performance of the material is directly related to the difficulty of the product heat dissipation design. Materials with high heat dissipation performance, the difficulty of the product heat dissipation design is relatively low, and the material with low heat dissipation performance, The difficulty of heat dissipation design is high. In addition, it is necessary to combine the appearance design of the product, and the shape and location of the heat dissipation holes need to be coordinated through the appearance design.

Excellent products must have superior stability. Stability is the most basic requirement of product structure design. If the structural design cannot solve the stability of the product, then the product can be said to be a failure. Recently, the explosion of Samsung mobile phone, which has been raging on the Internet, is not only related to the performance of the product battery, but also related to the incoordination and poor stability of its structural design and functional design. Therefore, the product structure design must first consider its stability and feasibility, which is the basis for the realization of product functions.

The copyright of this work belongs to 白狐设计. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Comment Board (0)

Empty comment