It took seven months to finally go public.

-Initial fee case

I may prefer this fabric and chrome plating, a soft and hard, homey and industrial-feeling strong contrast style. However, the following factors are limited by assembly, cost, vulnerability, and what kind of product is too similar to a capsule baby and cannot be related to medicine...

-Ventilated heating sleeping pad remote control part design

The following are some of the highlights of the product landing process

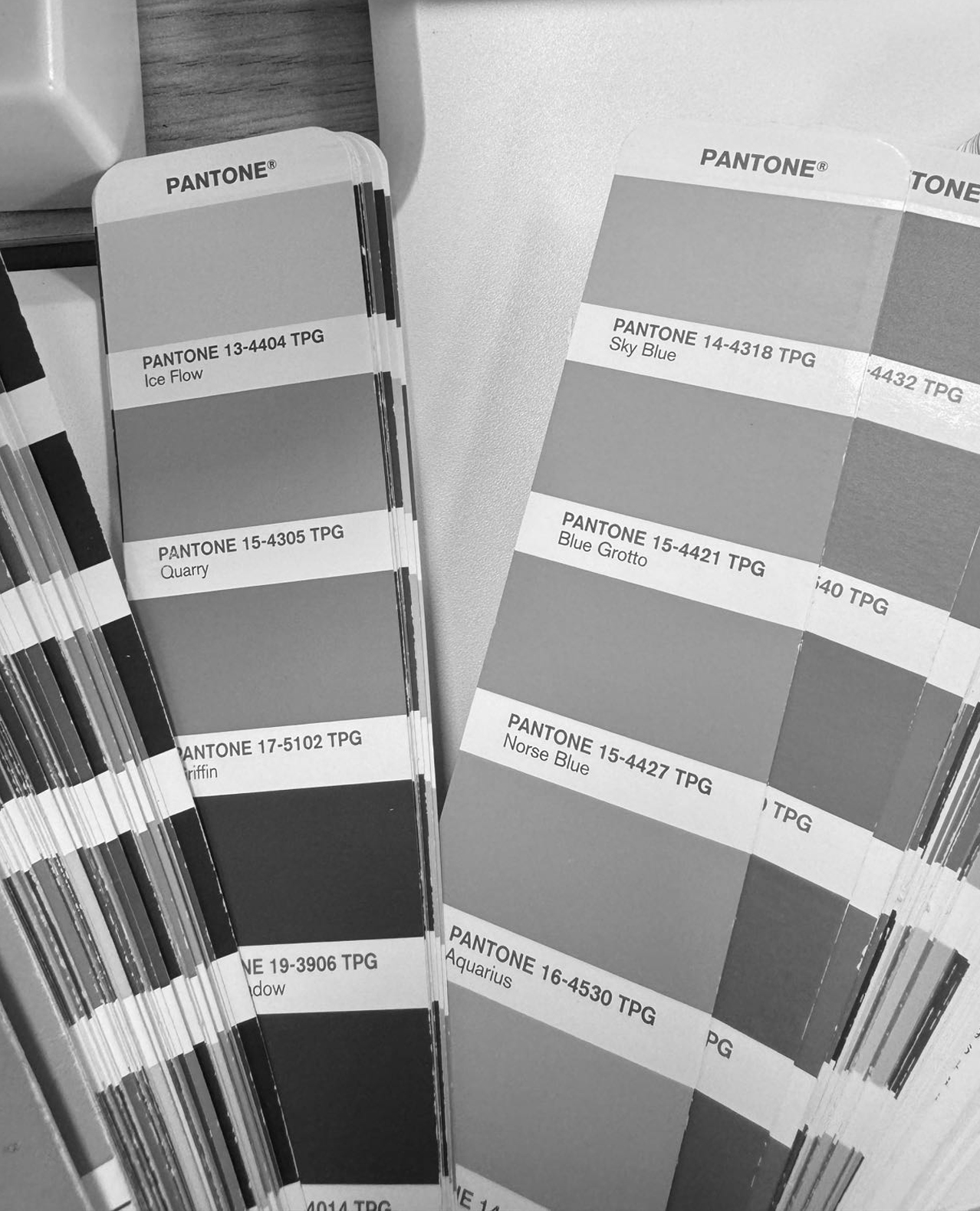

-Pantone color card selection gradient color

Gradual color cloth, dyeing factory is not dyed out. The dyeing factory can only dye solid colors. The process of printing cloth is used here. The basic principle is to first use the machine to print out the paper (which can be very large) with excessive gradient, and then paste the paper on the white embryo cloth to transfer the color on the paper to the cloth by hot pressing.

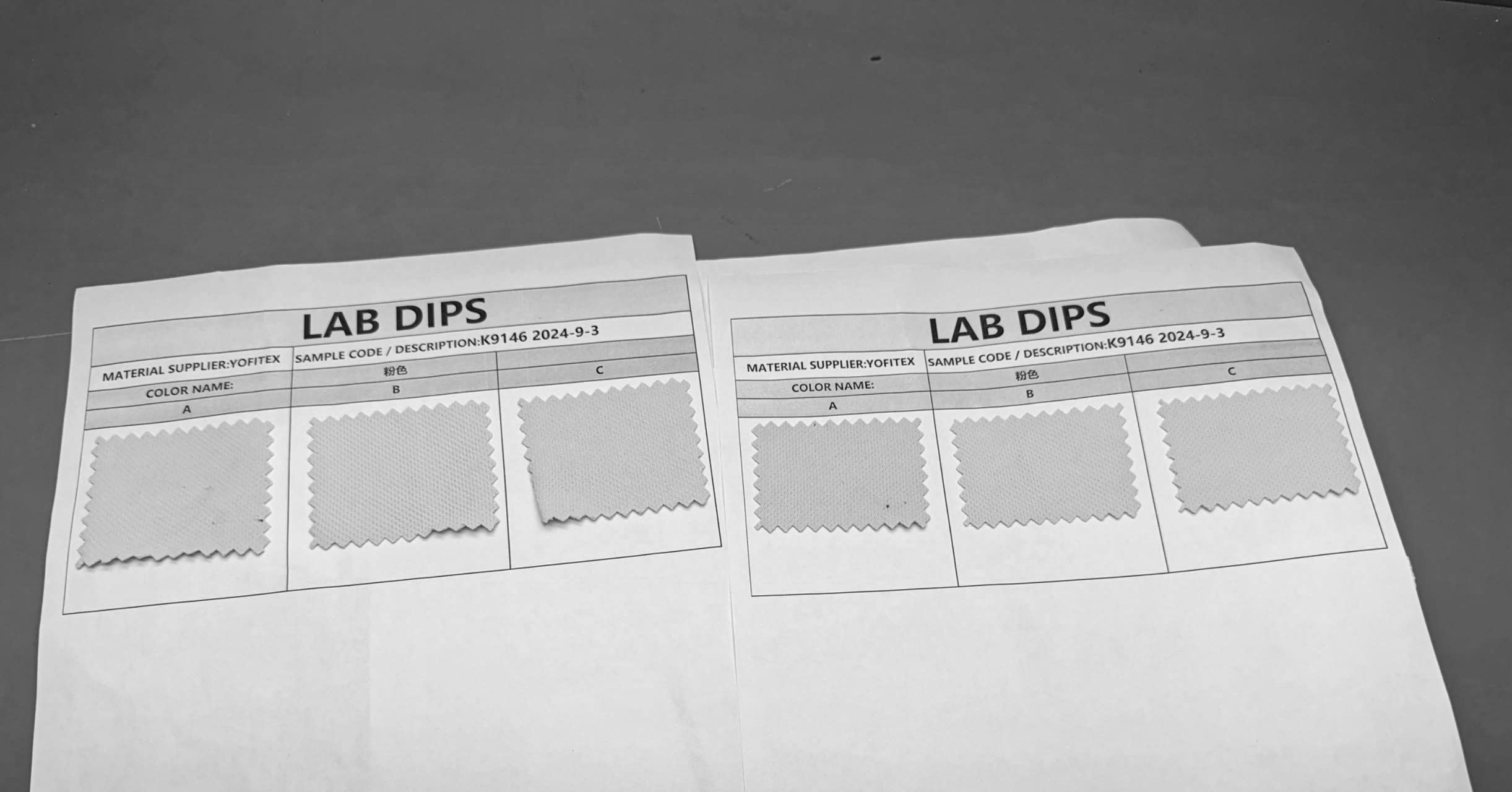

-ABC fabric swatch provided by the fabric factory

According to the color number of the deployment of a variety of similar colors for our choice. Sometimes it may be difficult to distinguish with the naked eye, and it needs to be placed in a professional color light box for comparison.

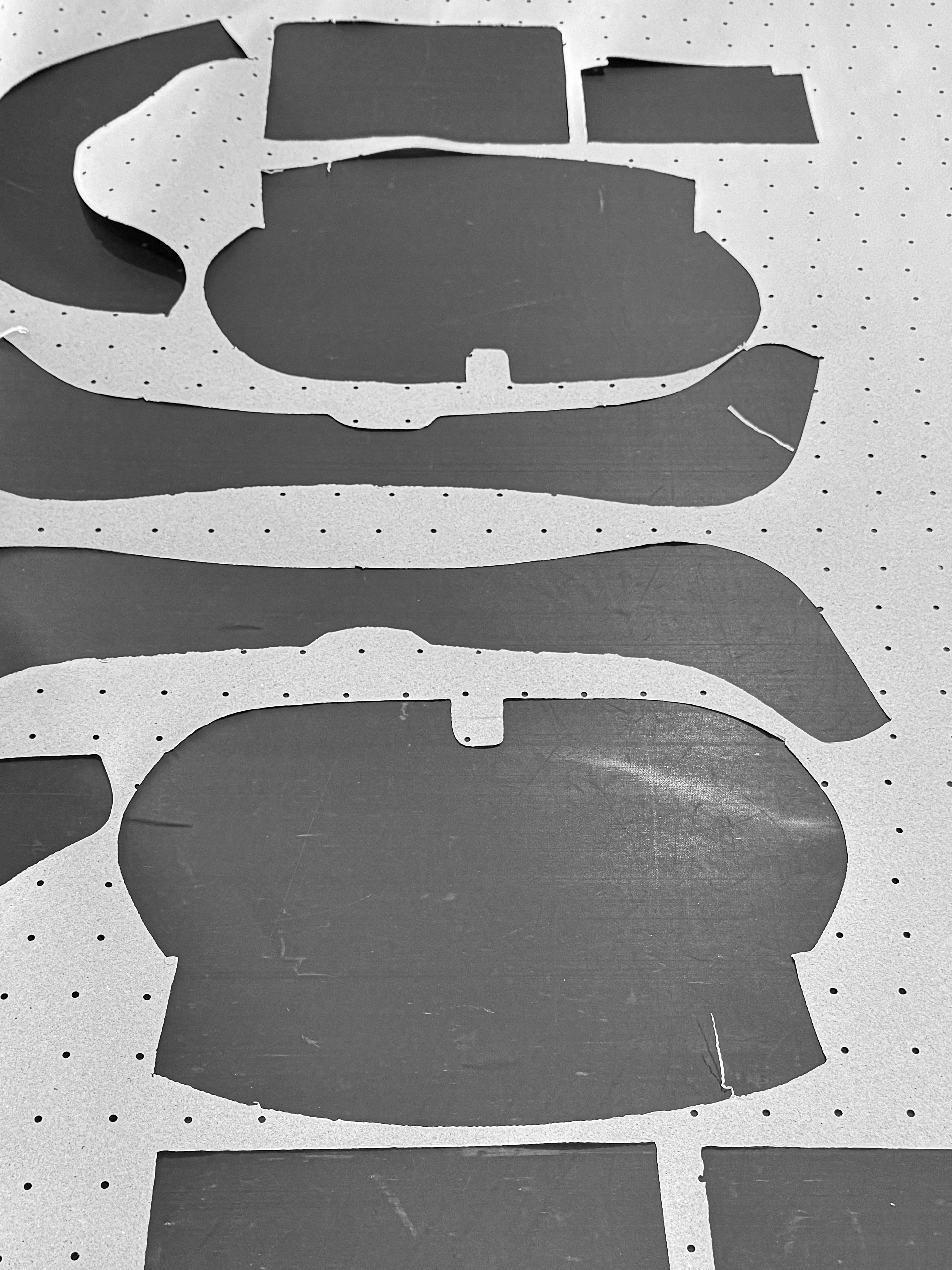

-Plate making and typesetting

[Plate Making] The cutting piece is made by the plate master in combination with the final effect drawing and the real hand plate sample. During the need for designers and plate-making master of continuous communication. For more complex versions, completely polished will be a relatively long process.

[typesetting] regular solid color cloth cover, a section has only one color. Therefore, the computer can arrange the cloth in the most compact and economical way. However, the gradient color cloth cover is unique in the size, depth and direction of the gradient area of each piece. We can only do manual typesetting at the moment. The machine can't handle it yet, so there will be an increase in waste. Of course, whether it is automatic or manual typesetting, the back is a cutting bed, and the machine cuts it out. After cutting and sorting, the finished cloth cover is finally made by sewing.

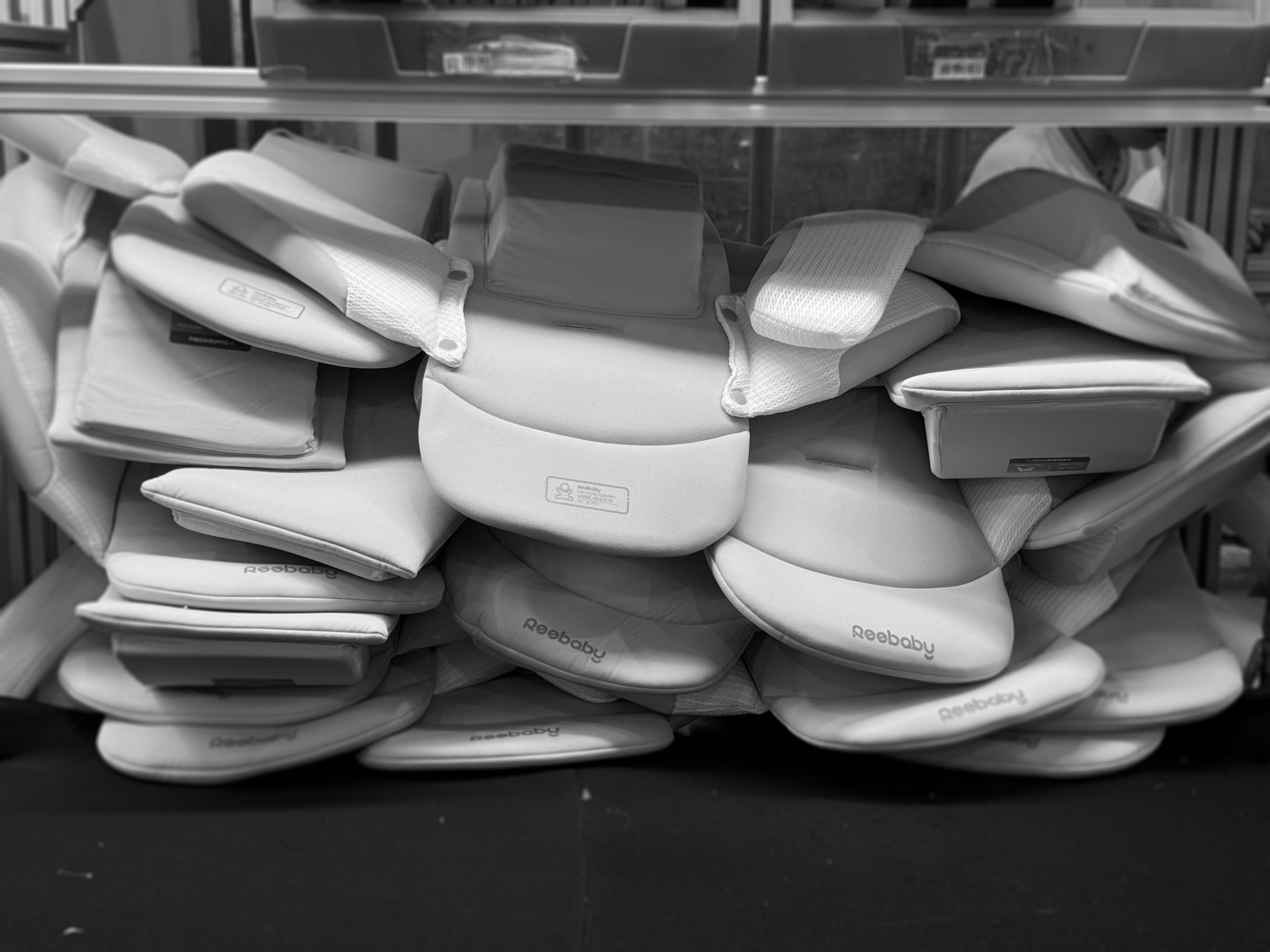

-Trial production

The copyright of this work belongs to 乐事. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

hand-painted: Procreate

Modeling: Rhino7(SubD)

rendering: Keyshot 11

Late: Photoshop 2024

Can you tell me how to do this kind of structure, and from which aspect to learn?

This is awesome, man. The top ten are so powerful.

Bullfrog

The other is soft power, this is hard power, excellent!

Novice Dad: Hello designer, is it convenient to ask if this can be used instead of slope pillow for feeding?

TOP has not been updated for nearly two months

It's great. Every place feels exquisitely crafted, especially for use (Sud may be skilled, so it won't be as troublesome as Nurbs wiring and matching). In reality, many ideas have to follow the cost required by the market... The most annoying sentence is just a simple appearance and it is not difficult! From 0 to 1 is the hardest.

Can the model project built by subD be used there?

Villager wow

Big brothers sell potato chips and can design, which is really versatile

Learn like a big man

Good product

Is this a baby ride seat