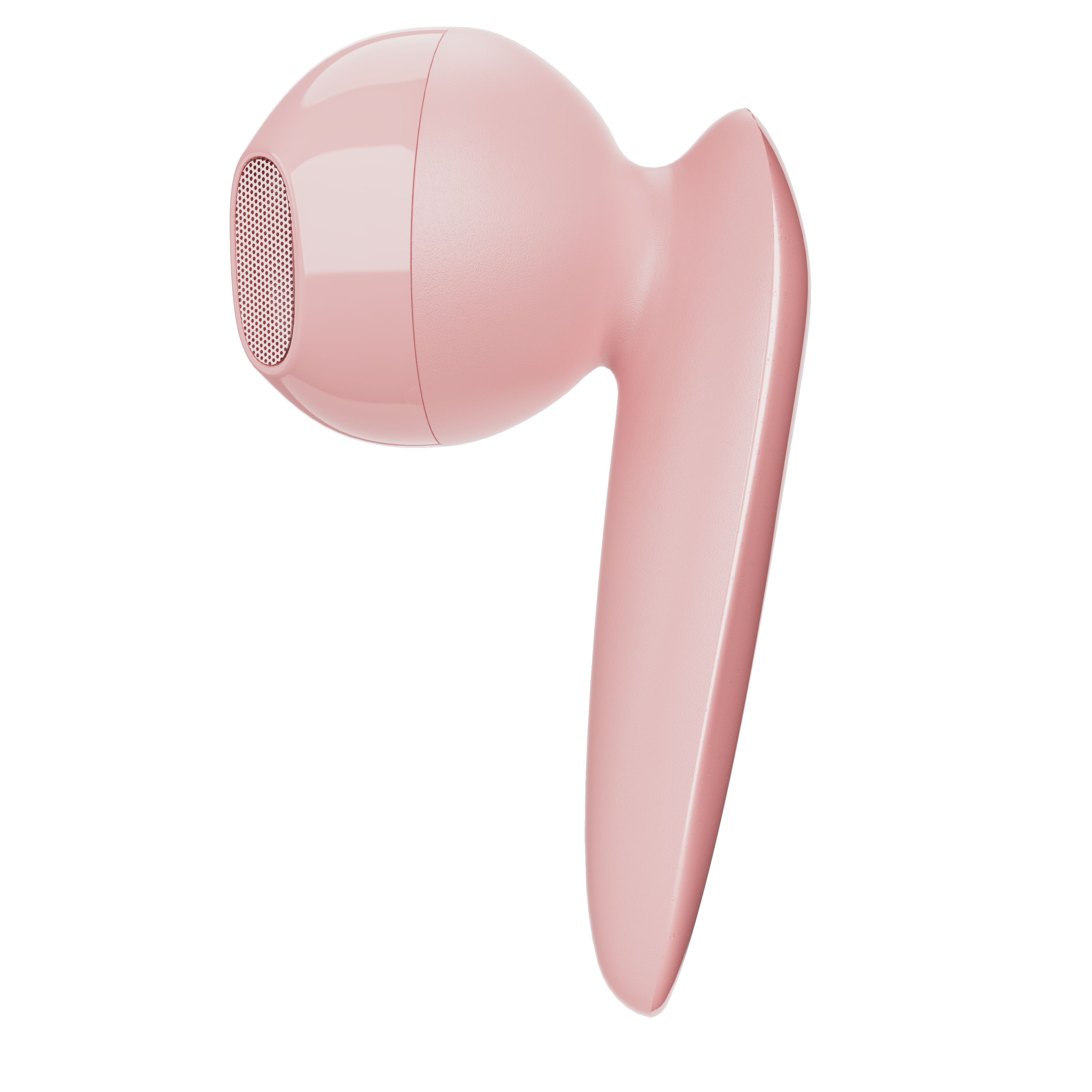

When designing Bluetooth headsets at ordinary times, the biggest headache is half-entry. To get rid of the shadow of Apple, you have to ensure enough space... the design was done at the edge of the crash. The product manager's voice has been buzzing in his ears, "put on 13MM horn," take a step back and put on 10MM, "" PCB board position is not enough, "" battery should be 40 mA, "" wear must be comfortable, "" 3D print back to see "......

Makeup powder box

Shell charging box

The copyright of this work belongs to 瘦龙. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

The overall feeling of the earphone is quite good. In the later period, more consideration should be given to the structural problems. After a little adjustment, the problem is not big, but the charging box feels a little big, and the lid of the charging box is inverted according to the ordinary mold, and the unconventional mold cost is too high.

I also do earphone ID, the place between the back cover and the mold dividing line of the middle shell is too sharp, and the contact should be relaxed. it is suggested to find out more about the relevant knowledge points of the bottom draft angle mold design. if you do this, there will be problems with the mass production mold, and the clear modeling positioning is also a bright spot.

The whole is not bad, but I feel the tail of the earphone is too sharp.

It's not easy, it always feels great when the product comes out