Under the background of a new round of consumption upgrading, the demand for personalized and flexible production and manufacturing in the industry is becoming more and more urgent. The composite robot integrates multiple functional characteristics of "hands, feet, eyes, and brain", and has gradually become the key equipment to respond to the growing flexible needs of customers.

Recently, Luoshi released a new generation of CMR series composite robots to meet the needs of flexible and intelligent production of more complex applications and subdivided scenes, and to enhance the production efficiency and economic benefits of enterprises.

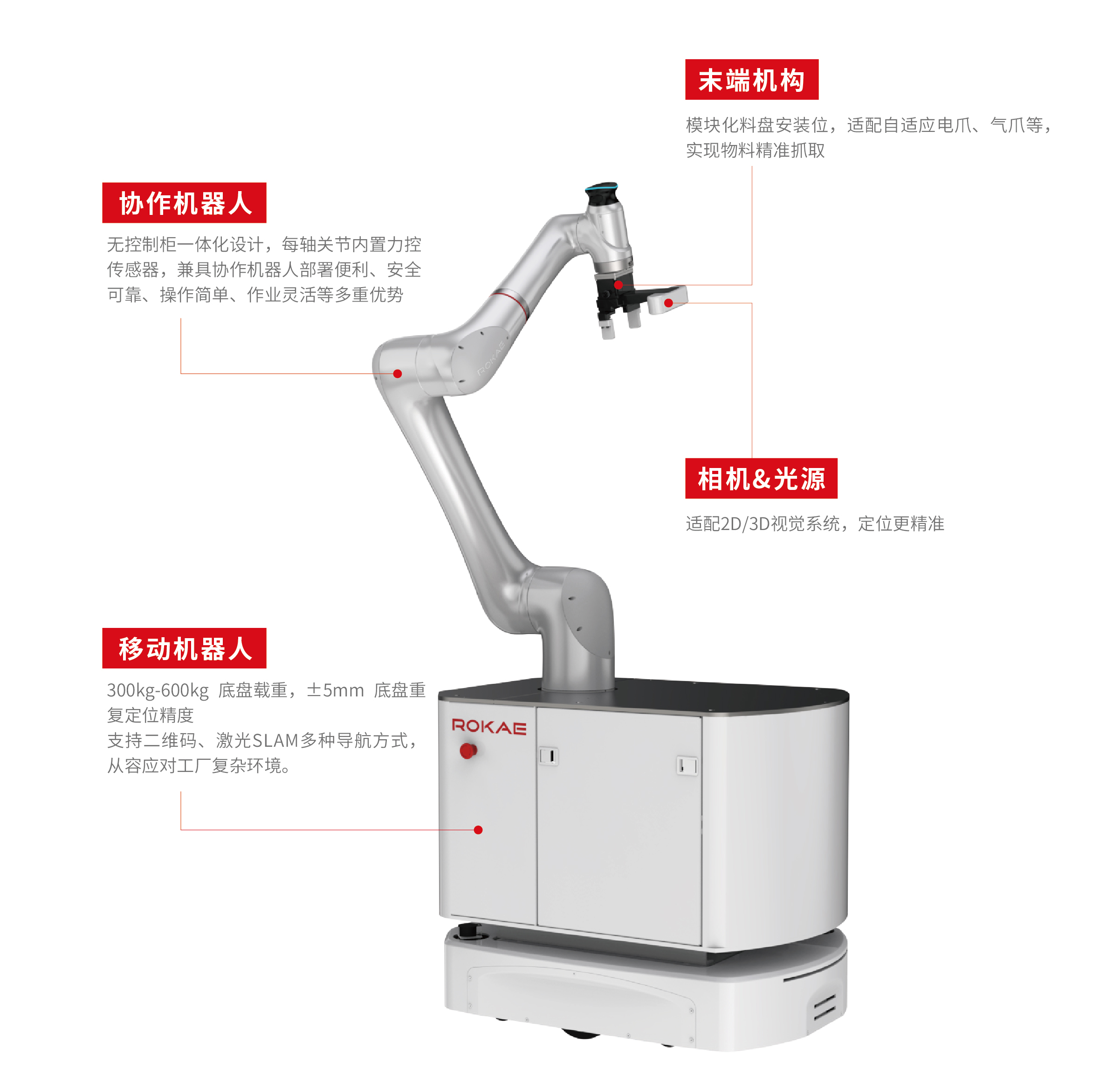

Luoshi CMR series composite robots can be flexibly matched with flexible collaborative robots, mobile chassis, 2D/3D vision and end tools.

The mechanical arm is equipped with xMate CR, ER and SR series of Luoshi flexible cooperative robots, with a load of 3-18kg and a working range of 580 mm-1300 mm;

The mobile chassis has a load of 300-600Kg, adopts laser SLAM navigation mode, can independently plan the path and build the environmental map, does not need to transform the site, and has strong adaptability.

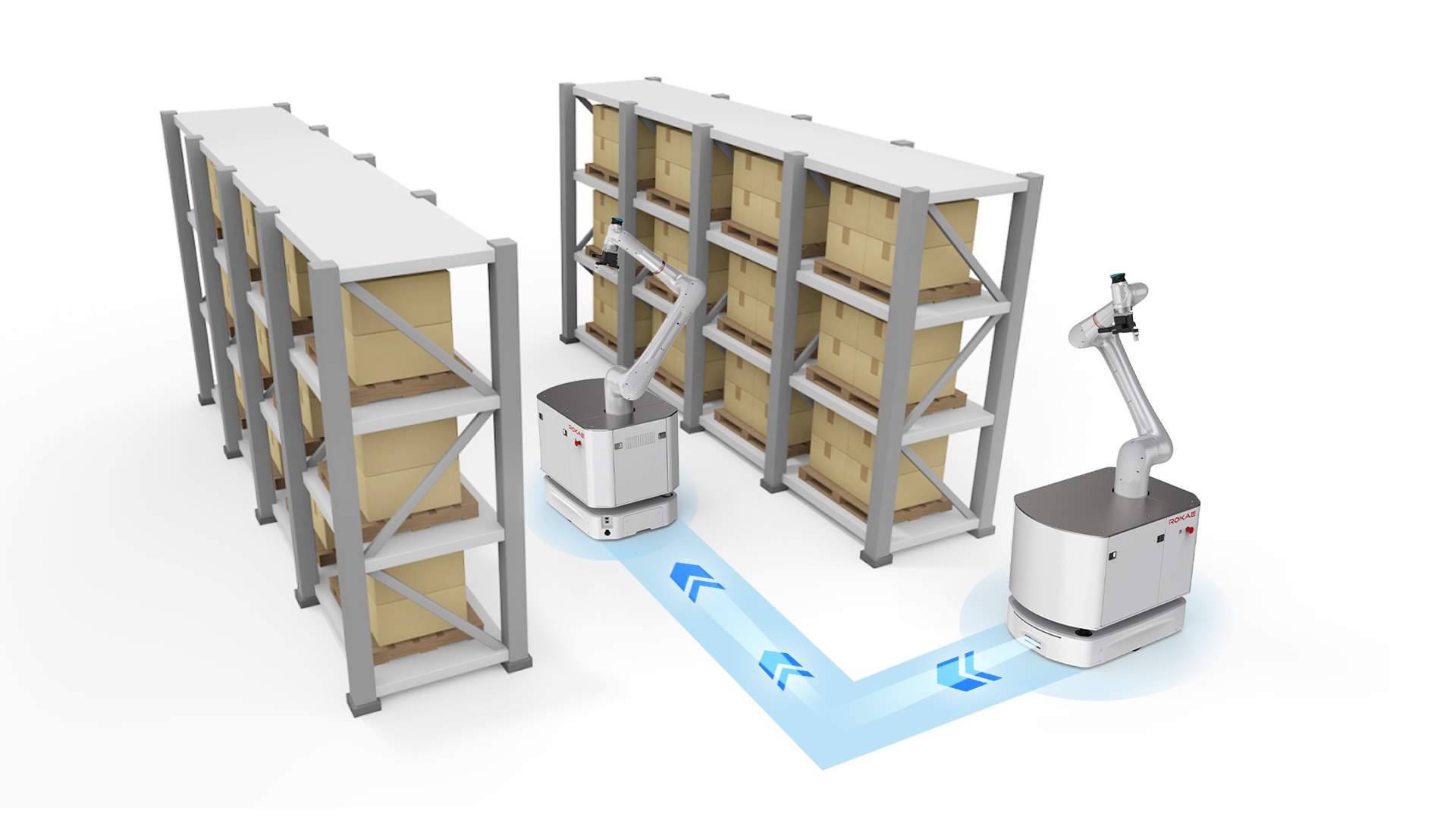

Through the flexible cooperation of "hands, eyes, feet and brains", Luoshi CMR series can easily realize various functions such as movement, identification and grasping. It can be widely used in scenes such as material transfer, CNC loading and unloading, visual inspection and equipment control, efficiently complete various complex or multiple tasks between different stations in the production and manufacturing process, and create an intelligent and flexible production process.

Six Advantages Empowerment Intelligent Factory Flexible Transformation

NO. 1 Simple and easy to use

Visual software operation, to achieve one-stop rapid deployment, at the same time equipped with an open scheduling system, seamless connection with factory MES, WMS, more convenient operation, easier to use.

NO. 2 Open compatibility

The robotic arm adopts an integrated body without a control cabinet, which makes the design of the composite robot system more flexible. At the same time, the chassis and robotic arm have multiple sensors, which make them more adaptable when dealing with narrow channels, compact production lines and highly dynamic and complex environments.

NO. 3 Flexible and flexible

Support laser SLAM, two-dimensional code and other navigation methods, perfect integration of factory layout, flexible and fast switching. It can also plan autonomously under complex paths and intelligently detect and identify obstacles.

NO. 4 Precision Intelligence

The navigation accuracy is 5mm and the absolute accuracy of the mechanical arm is 0.3mm, which ensures high precision positioning operation and realizes efficient circulation of objects.

NO. 5 Safe and Reliable

The mechanical arm has a built-in force sensor for each axis joint, which has sensitive collision detection capability, and has passed a number of functional safety certifications, making human-computer interaction and cooperation safer.

NO. 6 Cost-effective

Without changing the working environment, you can quickly build automatic map navigation and greatly reduce operation and maintenance costs.

"Hand, foot and eye" flexible collaboration to accelerate the expansion of application boundaries

[Case] Compound Robot CNC Machine Tool

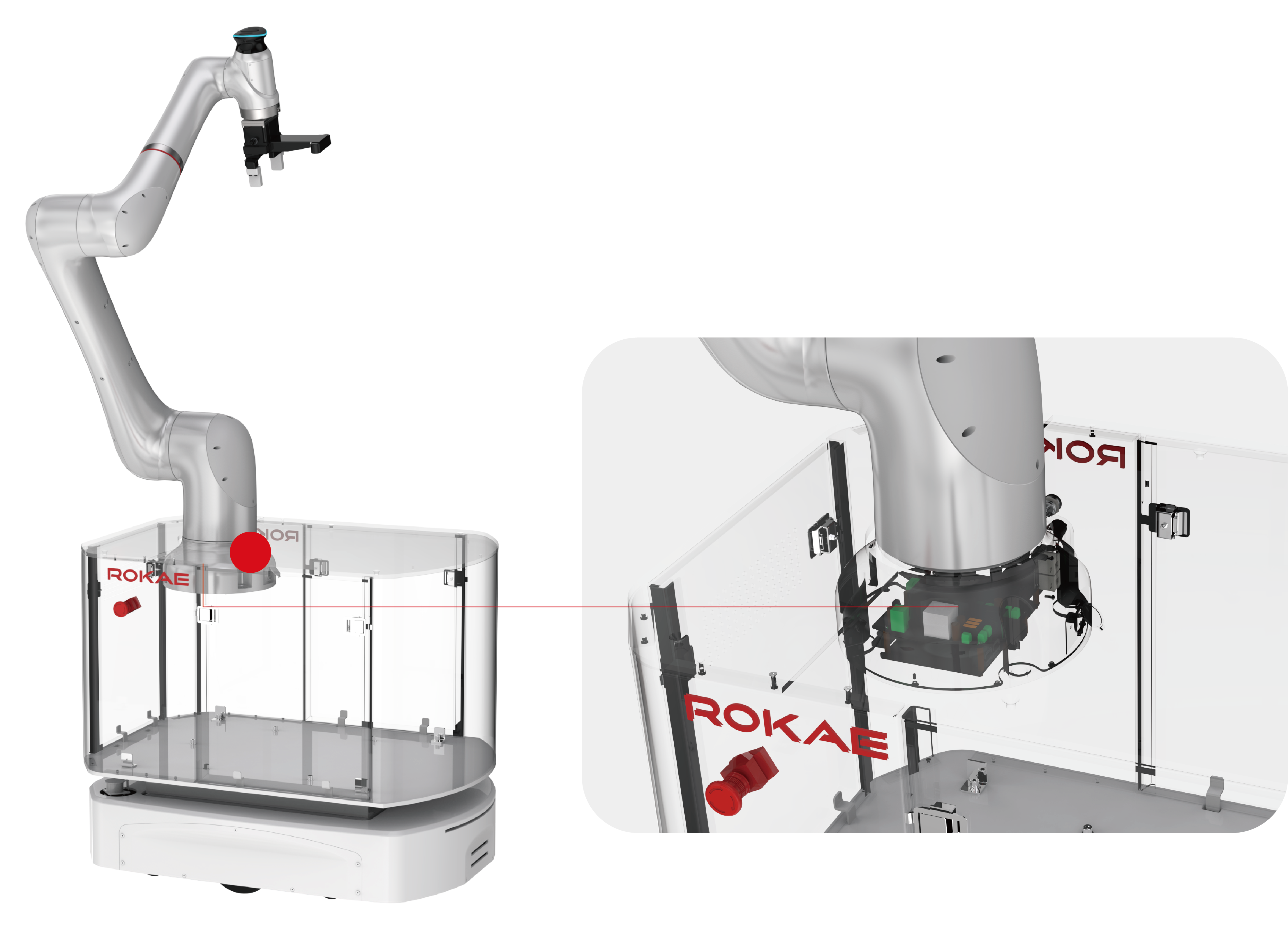

Enterprise pain point: a customer enterprise factory needs to realize the automation of material tray transfer, improve the level of factory automation. Due to the splashing of cutting fluid in the machine tool, the tooling allowance is small, and high-precision picking and placing are required, which requires high precision and protection of the robot.

Solution: Luoshi composite robot effectively solves the above pain points. The equipped cooperative robot has a high protection level of IP67, and the harsh environment in the machine tool can also be easily dealt with, without fear of cutting fluid and oil corrosion, ensuring long-term efficient and stable work. The robot meets the requirements of high-precision pick-and-place, can ensure accurate loading and unloading each time, and monitor and adjust the force of parts in real time during the pick-and-place process, effectively avoiding damage to parts.

Customer benefits: a composite robot corresponding to 20 machine tools at the same time, to replace at least 2 human workers, greatly improve the accuracy of the operation and loading and unloading rhythm, has been in the customer site batch application and achieve long-term stable operation.

▽ More compound robot applications ▽

Luoshi composite robot is simple, easy to use, safe, reliable, flexible and flexible. It has been widely used in 3C electronics, semiconductors, machine tool processing, general industry, medical and health care and other industries. It is believed that with the in-depth advancement of intelligent manufacturing, Luoshi composite robots will rely on their powerful superior performance to help more enterprises and factories reach a new level of intelligence.

The copyright of this work belongs to 珞石机器人ROKAE. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Great.

Qiang!

Can have a very wide range of applications

Too professional

High