The copyright of this work belongs to 董明亮. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

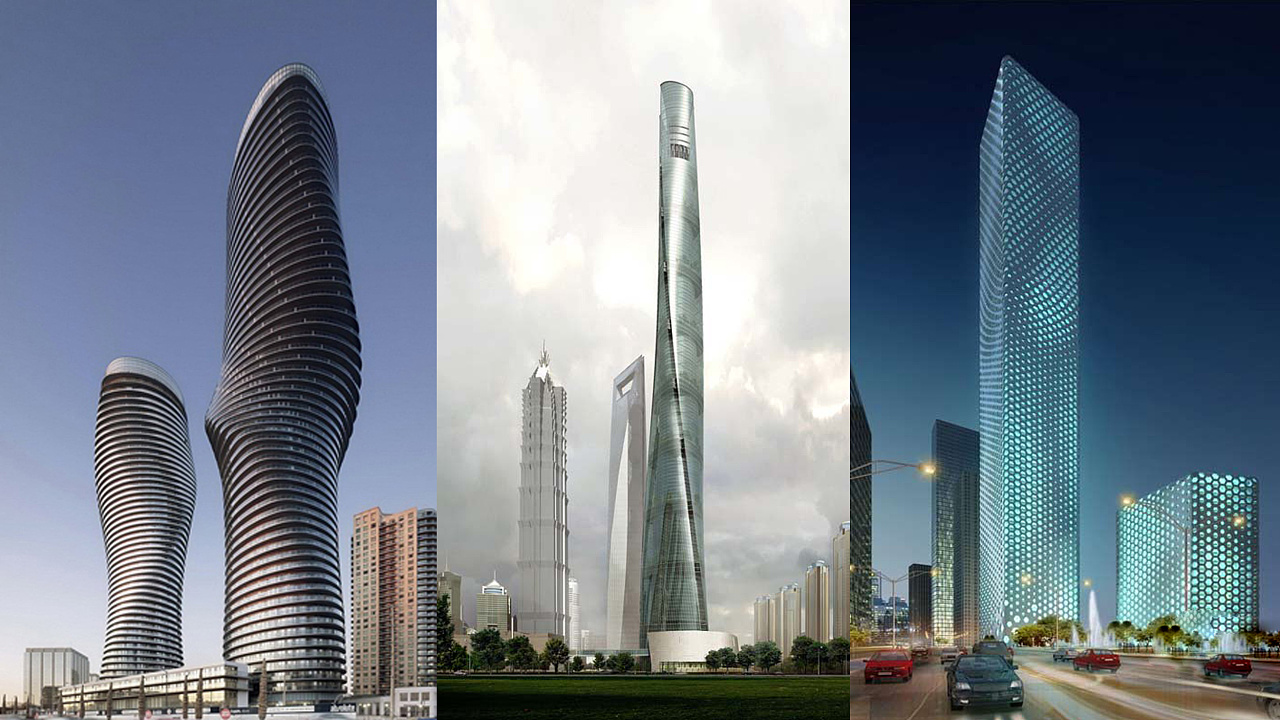

The idea is very interesting

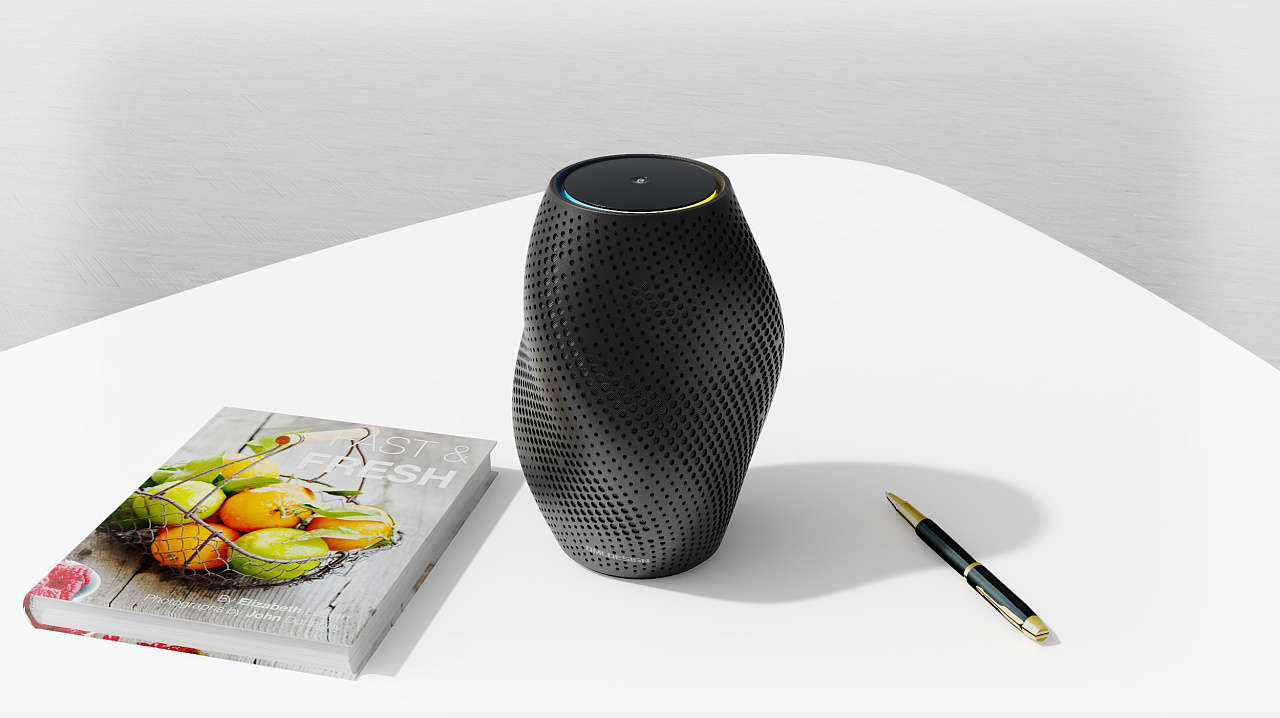

The parting line, this kind of shape can't come out of the shell,

Only I feel sick?

It's cool, it's a bit bloated, it will feel like dancing when you turn it around.

Are you Dong Mingzhu's brother

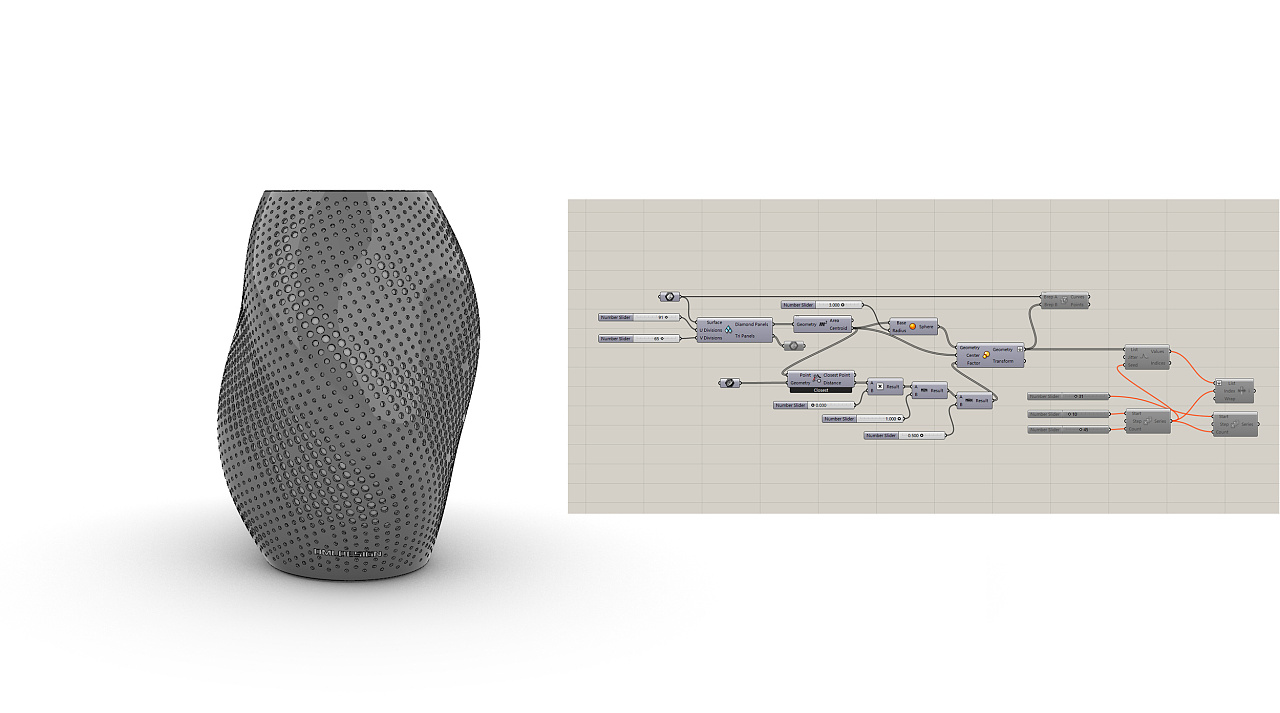

I did a similar thing years ago called# direct action# but added some conceptual functional modules

If you want to learn grasshopper, do you have any recommended tutorials? Thank you!

The front and back halves will not be molded and will be scratched! The overall shape is thinner and taller, but now it is slightly short and fat.

Call Rhythm

The middle frame is metal, how to mold it

Organic design, stick.

Praise

How is this modeled? Great

What is the name of this speaker better?

Looking at the rotation, my eyes are a little dizzy