In 2021, we received a cooperation invitation from Moxin Technology to design a desktop 3d printer in the form of FDM (fused deposition modeling) that can open the gap with market products. I am very excited because I like technology products very much and prefer to design products that can subvert tradition.

FDM due to its technical form, its natural defects are obvious (accuracy is not up to industrial production). But the advantage is that the price is cheaper, safe and non-toxic, suitable for families and small workshops.

The status of FDM printers:

1 modeling factory equipment sense is relatively strong.

2 large vibration, low stability, the probability of printing failure is relatively large. The vibration caused by the swing of the mechanical arm is large, which brings great challenges to the stability of the printer.

3 Without intelligent detection, it will continue to work after printing failure, causing a lot of waste.

4 Leveling accuracy is not enough.

5 The printed model is troublesome to remove the bracket.

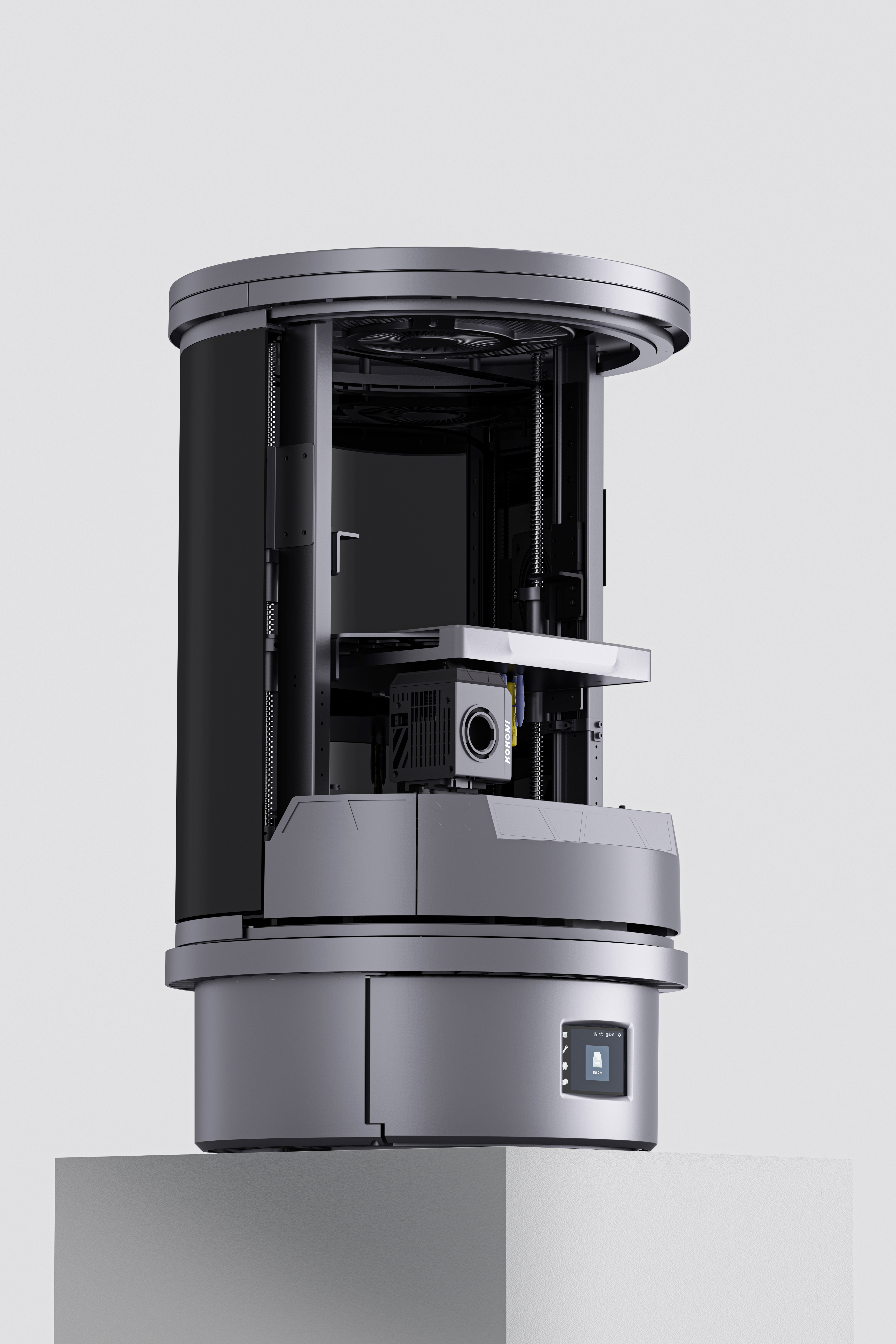

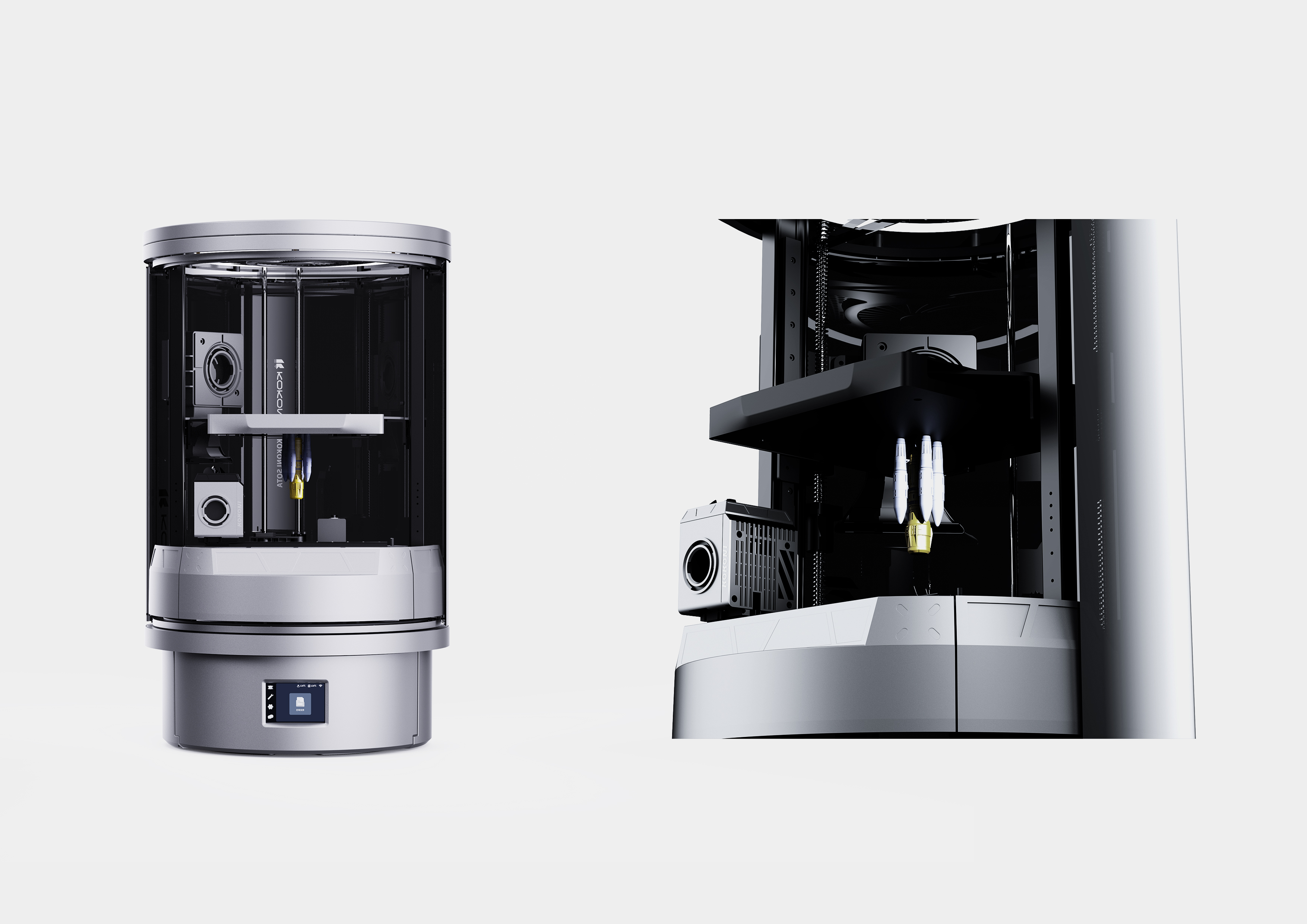

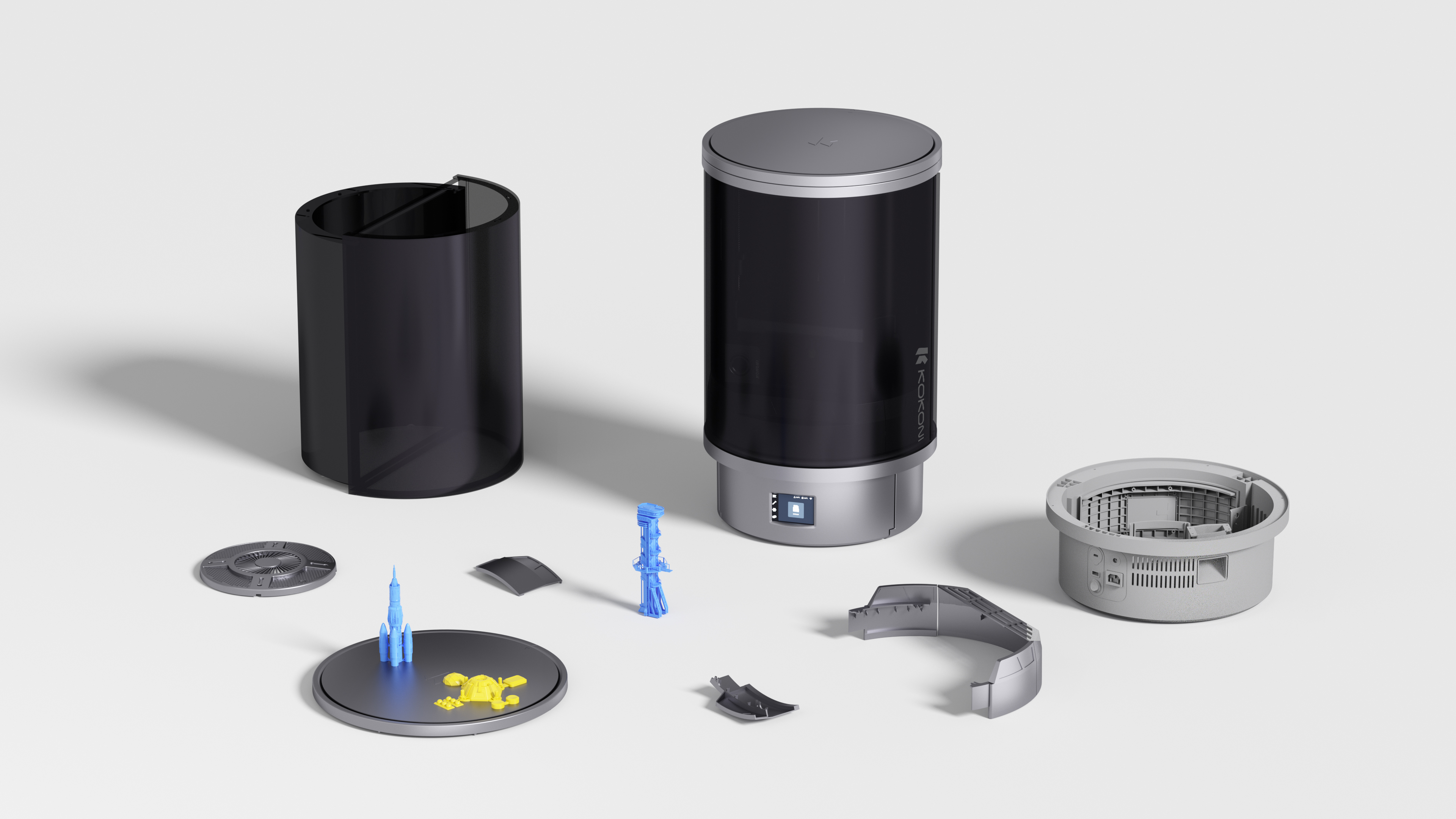

Since FDM printer is used by families and small workshops, its shape should give people a visual feeling of safety and technology. One day I saw the cloning room of science fiction films. The 3d printer that also produces various items should be similar to the cloning room.

Completely subvert the traditional, advanced products, the English word state-of-the-art just can convey this meaning. So call it KOKONI SOTA Pro

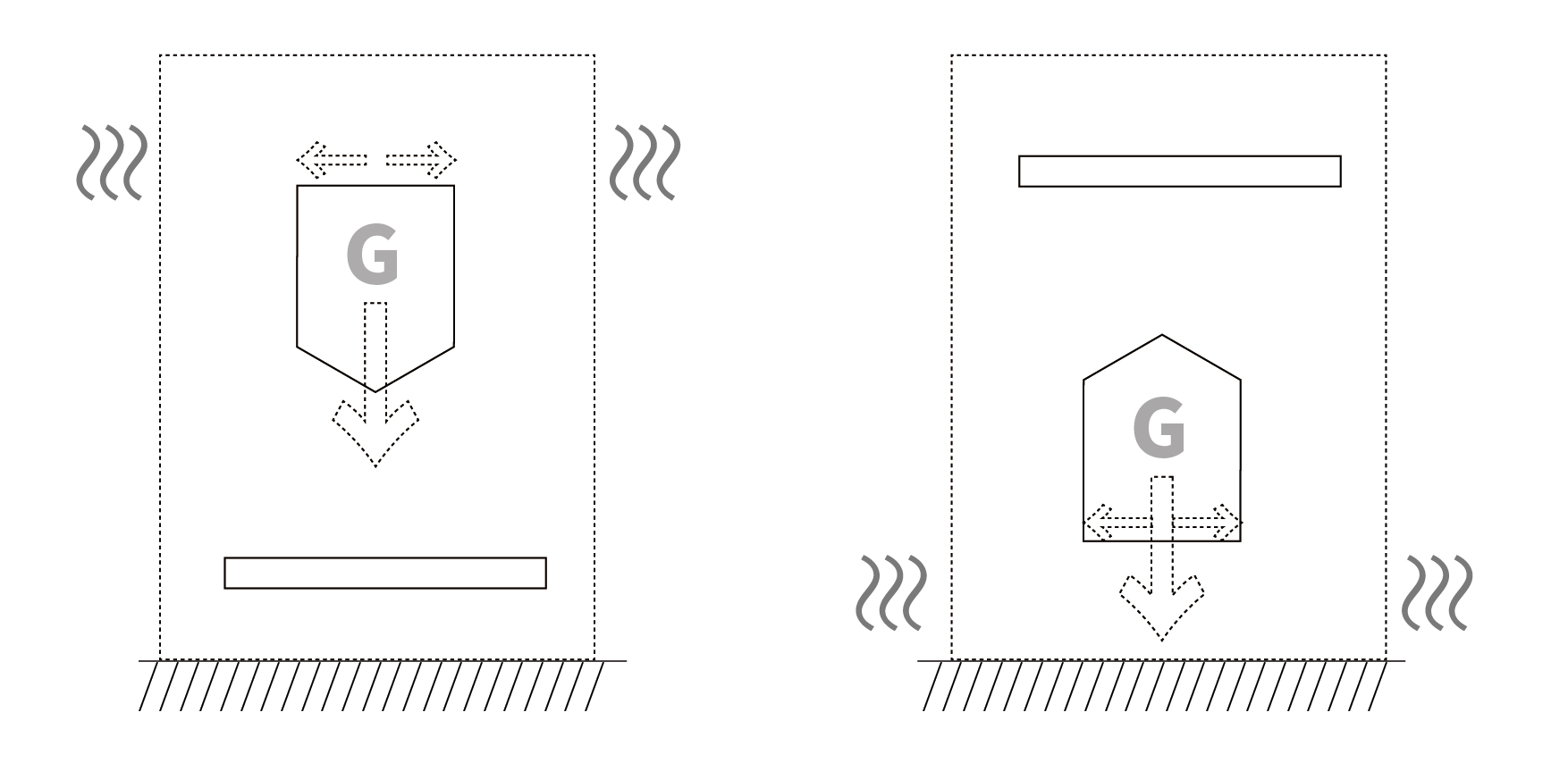

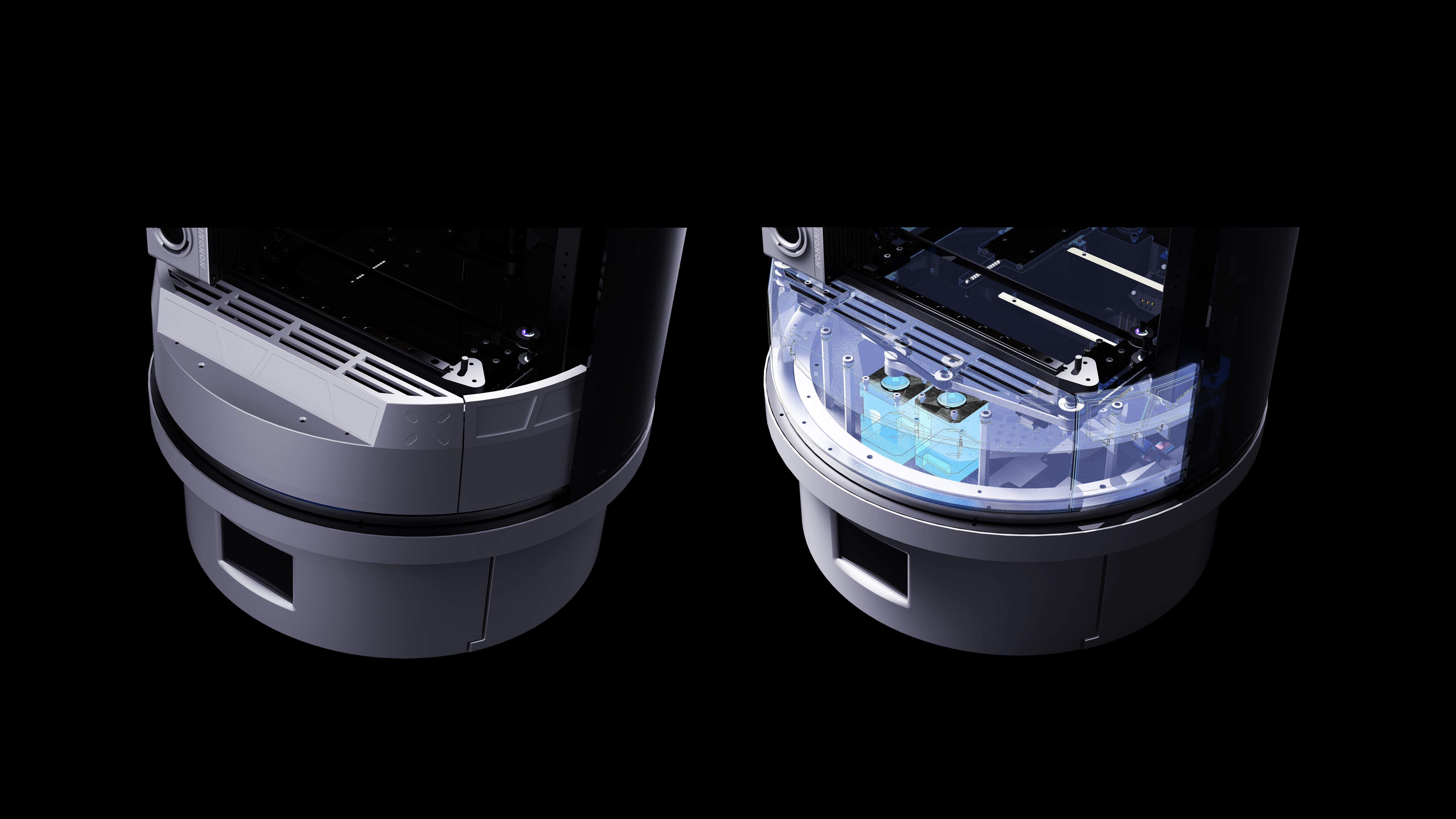

Due to the problem of product vibration caused by the movement of the discharge nozzle, the product vibration will increase the probability of printing failure. The discharge nozzle of the general FDM printer is at the top of the product, the center of gravity is at the top, the torque is large, and the vibration amplitude is greater.

In order to alleviate this problem we put the discharge nozzle design at the bottom, low center of gravity. And moving up and down is a stable support base.

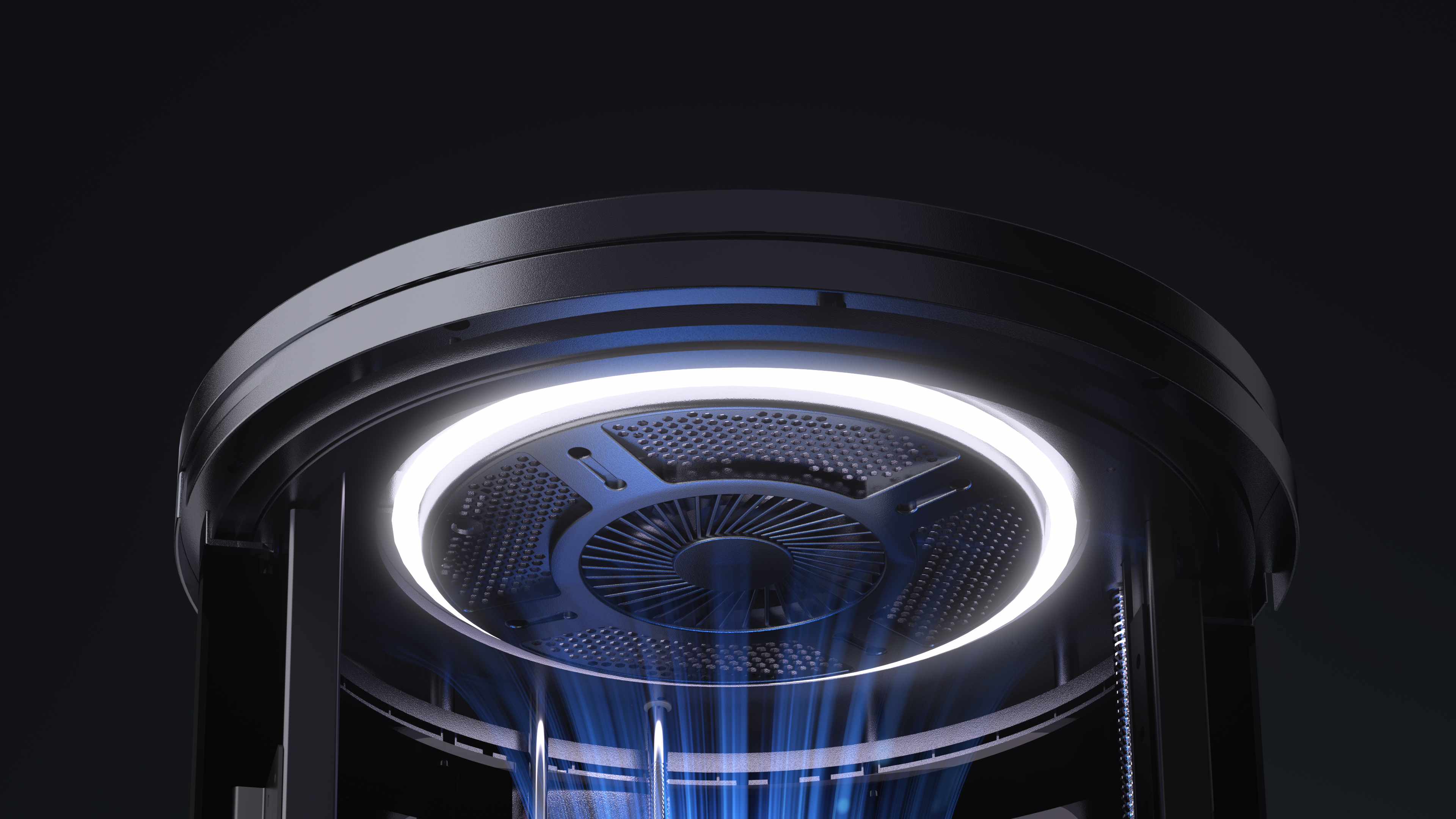

The stability is improved and the printing speed is faster. The KOKONISOTA Pro printer is 10 times faster than the traditional 3D printer, and the movement speed is up to 6000 mm/s. In addition, the anti-gravity filament jet reduces the support material of the product. The support structure no longer needs to resist gravity to support the entire printed object. Instead, the object is printed upside down in KOKONI SOTA Pro, which can reduce plastic waste by 20% to 50%.

KOKONISOTA Pro internally integrates the closed-loop integrated control of the industry's first consumer-grade 3D printer, which can record and adjust the current position in real time to avoid printing errors.

At ordinary times, the use of our AI camera can monitor the printing process of the product in real time and find errors in time. There will be no more printing errors and a mass of waste.

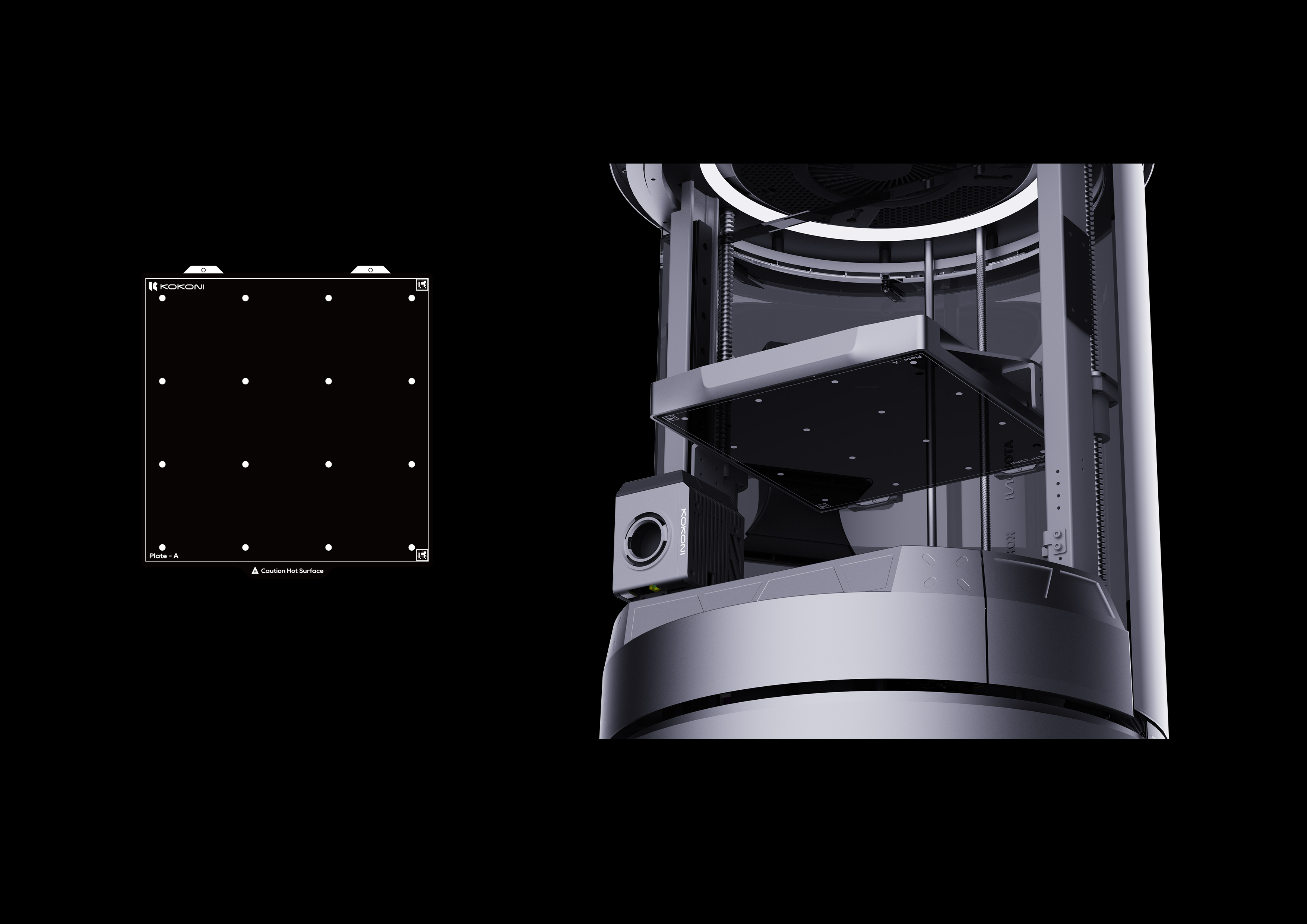

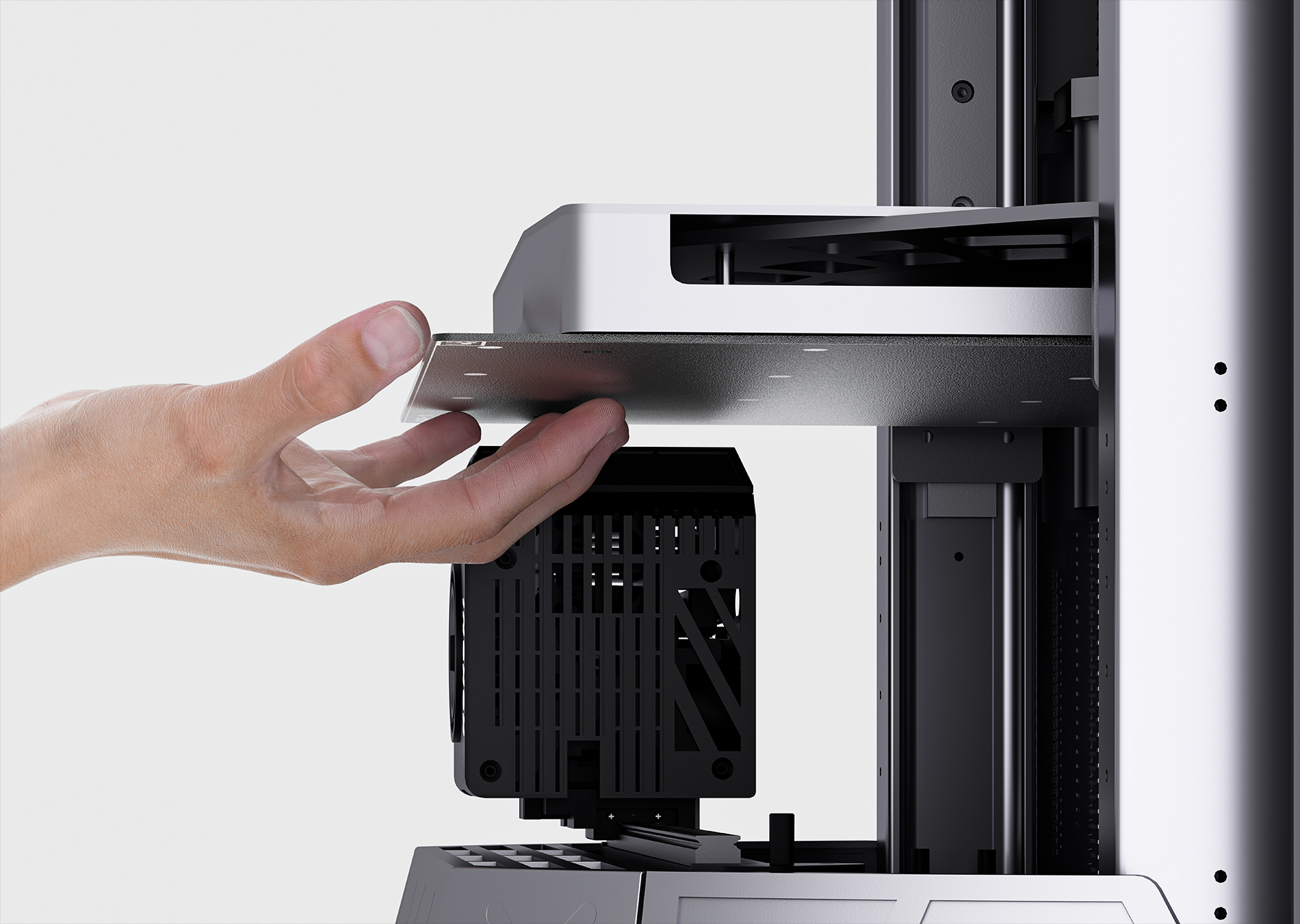

The supporting model board pioneered the 16-point capacitor leveling method. It is different from the traditional pressure sensor leveling which is easily affected by ambient temperature. 16-point capacitive sensing can accurately know the flatness of the platform with 0.05 accuracy, automatically complete the first layer compensation, printed optical marks, and cooperate with the camera to interpret the installation status of the printing board. The supporting plate comes with heating to stick the printed object.

Plate magnet adsorption, can be bent, quickly remove the model.

Built-in heat conduction fan, heat dissipation to prevent the temperature of the printed object from being too high and affecting the printing effect.

Open the coil, you can replace the wire. One of the two wires is a water-soluble support material and the other is a printing material.

App has a large number of models to choose from, built-in AI algorithm, can identify physical world objects into data models, and print out. Really print everything.

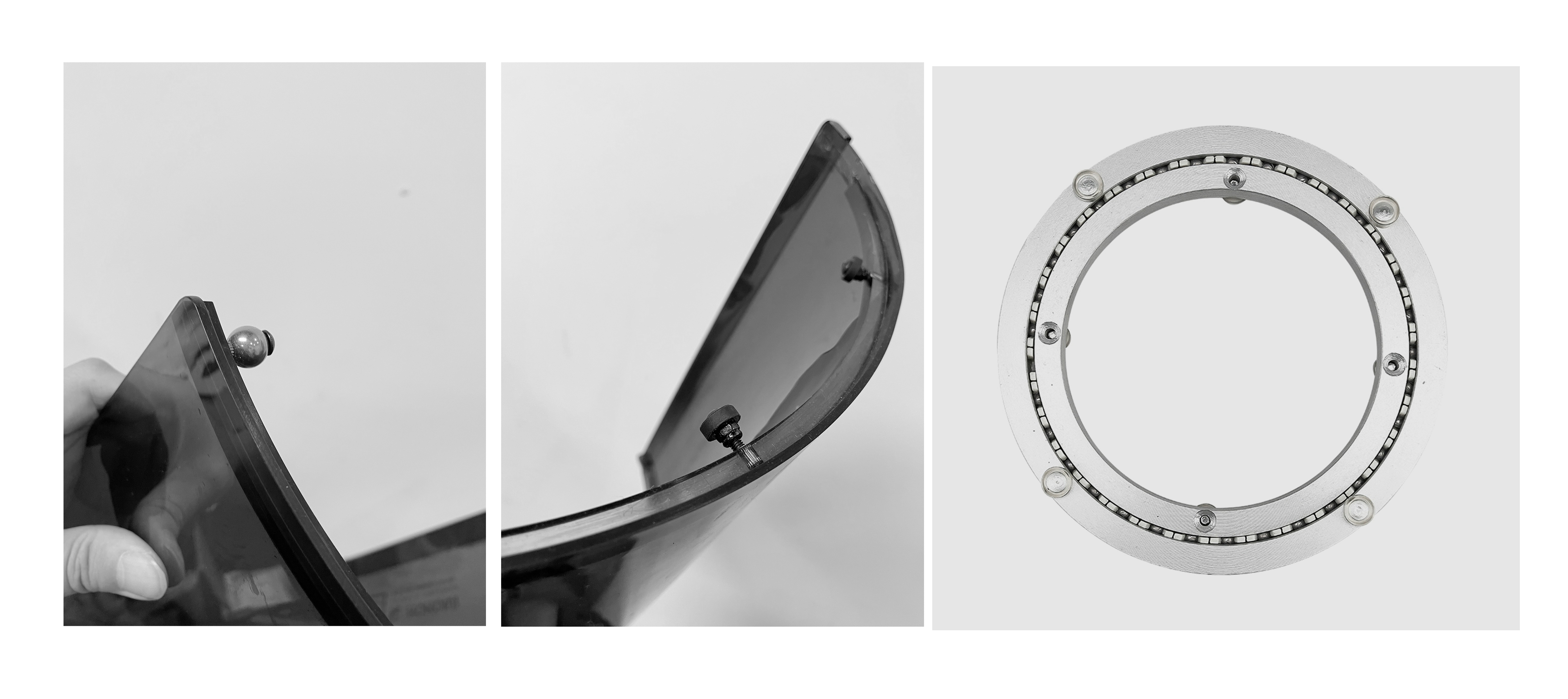

The price of innovation is that the cost of research and development is too high. Lasted three years, repeated proofing verification adjustment. For example, the sliding mechanism of the door, just started to refer to the circular slide rail of the bathroom and tried to use the pulley. It was found that the pulley noise was very large, and it was difficult to achieve the expected effect due to the large error of the PC material door. Then I tried to make a PU rod car into a sphere, but I still found that the problem of accuracy was difficult to control, the noise was loud, and it would get stuck.

Finally, we customized a quiet rotary bearing similar to the dining table. Although the cost is higher, it also has a better effect.

The copyright of this work belongs to 冒险岛设计MAOOXD. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Design is reference

Brother, I 've been collecting products for several months, but they haven't been on the market.

What kind of software is this modeled?

If the printed item is broken and falls to the running nozzle, will the machine be scrapped?

Niubi

Big Brother begged to put the physical picture, the physical picture is too handsome

Good job, I have also done printer design.

new ideas, do you have printed photos of finished products

What is the print range?

Looking for like-minded product designers who are willing to work deep in the design industry. Please contact WeChat 15012907157

Xie always can't hold a lucky draw

take money

Did Newton promise to do that?

You this is light curing lift, fdm hot melt extrusion. The feeling of inverted day ha ha.

Very interesting innovative ideas, looking forward to the actual print effect