This project was a failed project when designing the company before. Party A did not give any requirements but only required innovation, so it came up with this plan.

Because I don't know anything about the structure, the structure definition of the whole product is in an idealized state. Party A thinks that the structure is complex and difficult to realize and finally did not adopt it. Therefore, I share the scheme, hoping to have some inspiration for all colleagues and the wall-breaking machine industry. If there is a manufacturer who has a crush on the idea, he can develop it himself. After the research and development is successful, he can let me know. That is a great encouragement to me.

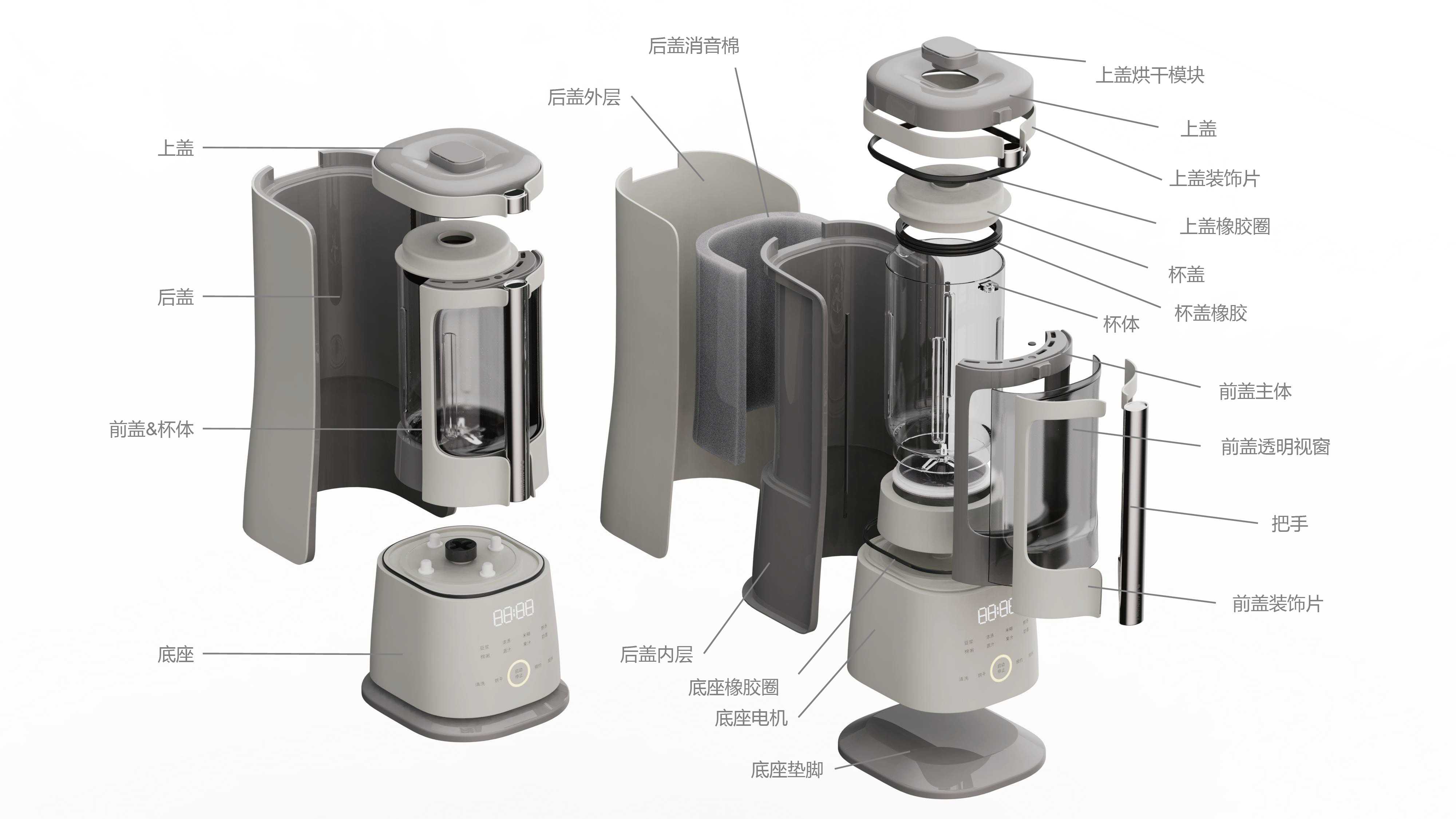

At present, when the mute cover wall breaking machine on the market is used, it is necessary to remove the mute cover with both hands and then take out the inner machine. There are four steps back and forth, each of which is relatively laborious.

The purpose of the design is to reduce the inconvenience of taking and installing, and use the elastic cover structure to disassemble the outer cover, making it easier to use.

The copyright of this work belongs to 蒋修. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

There are no structures that cannot be realized, only unaffordable costs.

I feel that production can be realized, but the cost is a little higher. Party A may not be able to afford so much mold opening cost. There should be no problem for larger enterprises.

the details are very good

It's really high.

very good ha ha

Not simple

High-tech