As early as 2019, the Realsee team of Rushi cooperated with LEAPX to design and develop the stand-up space scanner-Galohua. This product has become a new benchmark in the industry in the past few years and has been widely praised in the industry.

In May 2022, in order to cope with the growing demand for scanning, the vision team once again invited our LEAPX team to carry out design and development cooperation to build a mobile scanning device-Poincare.

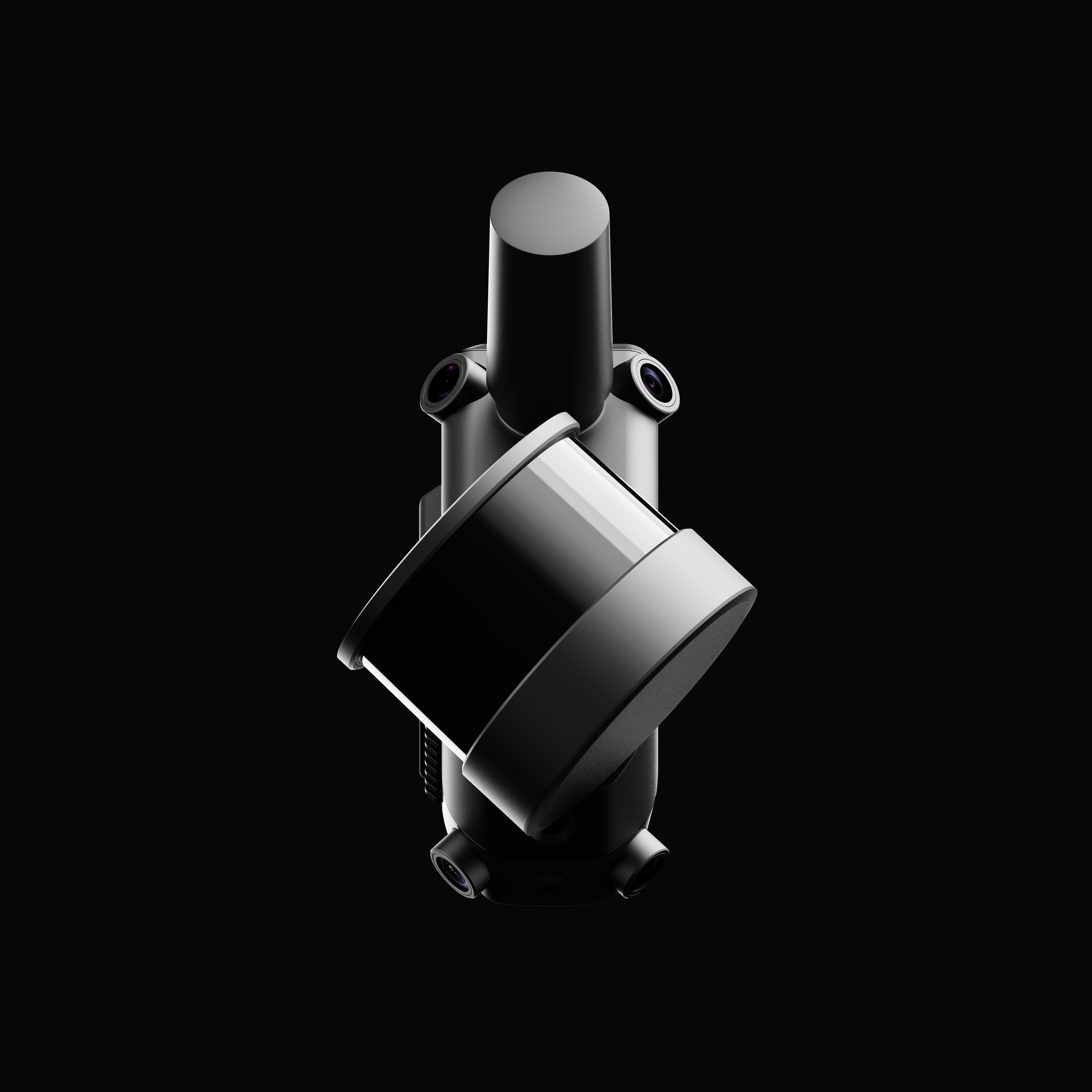

LEAPX led the configuration design from the early stage of the project. Under the reasonable layout design, Poincare scanner finally adopts multiple SLAM technology. LiDAR and camera cooperate with each other and do not interfere with each other. With the support of powerful software algorithms, Poincare has become the first laser scanning device in the industry to support full-view color point cloud in the machine.

Behind the design

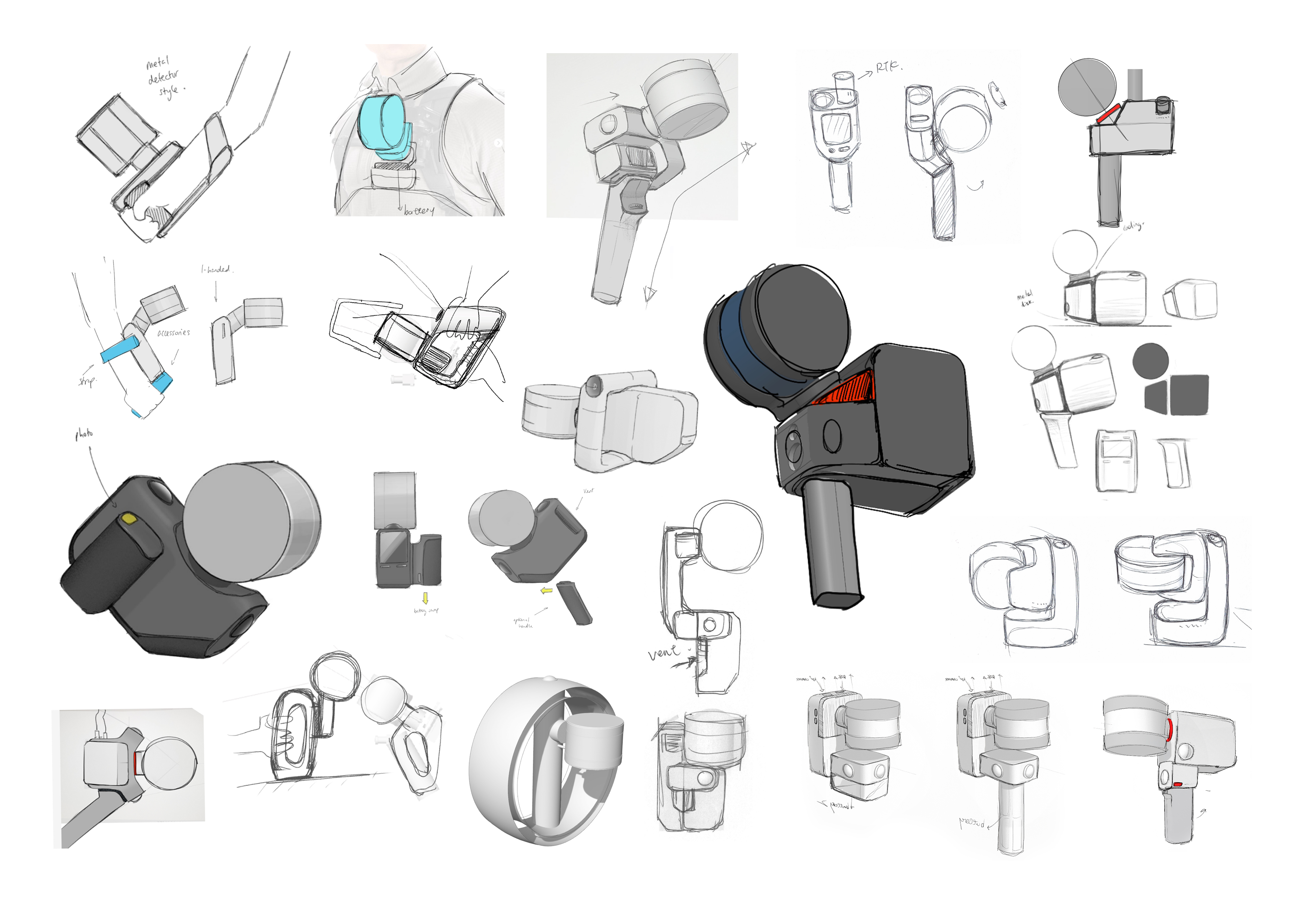

Mobile scanners need to move continuously during the scanning process to cope with the complex and changeable scanning environment. How to design a professional scanning device that is light and flexible, strong in performance, comfortable to hold, and able to cope with changing environments and adapt to multiple carrying platforms? This is a design challenge that the LEAPX team needs to solve.

In the early stage of the project, the LEAPX team conducted expert interviews and research, and personally used the scanning equipment on the market to collect user needs. I also experienced professional handheld photography equipment and learned about the architecture design of equipment in other industries.

Pain points: the biggest complaint of users about the existing mobile scanning devices is that the handheld devices are too heavy and long-term holding leads to serious muscle soreness. Although wearable devices solve this problem, they are too large, have poor flexibility and are difficult to carry when going out to work.

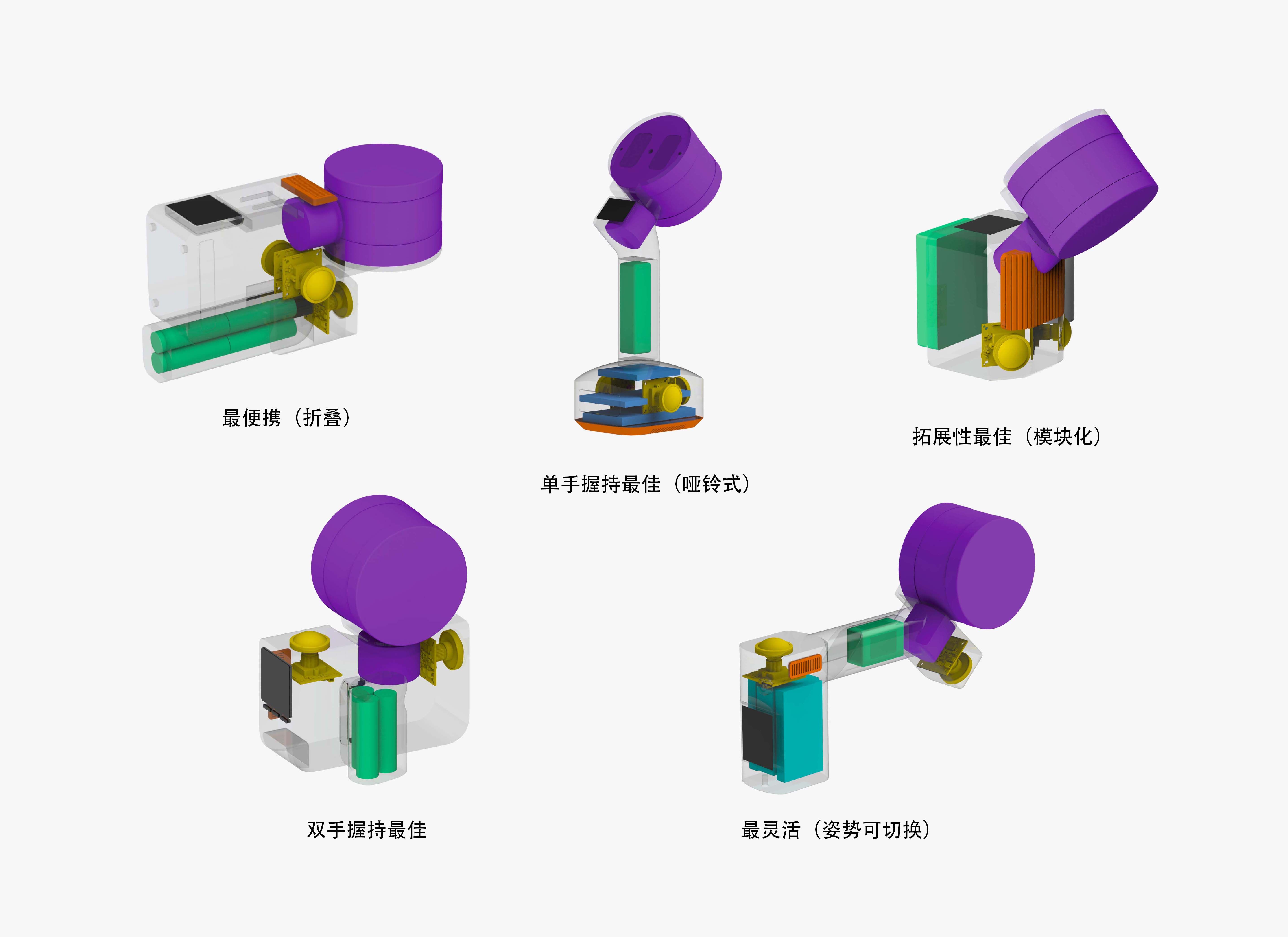

The LEAPX design team explored multiple dimensions of portability, grip experience, and maximum scanning performance through product configuration design in the early stages of the project.

The handle can be folded to reduce the volume and facilitate the outer belt.

Placing the camera module under the handle not only reduces FOV (visual range) interference, but also achieves the best weight balance.

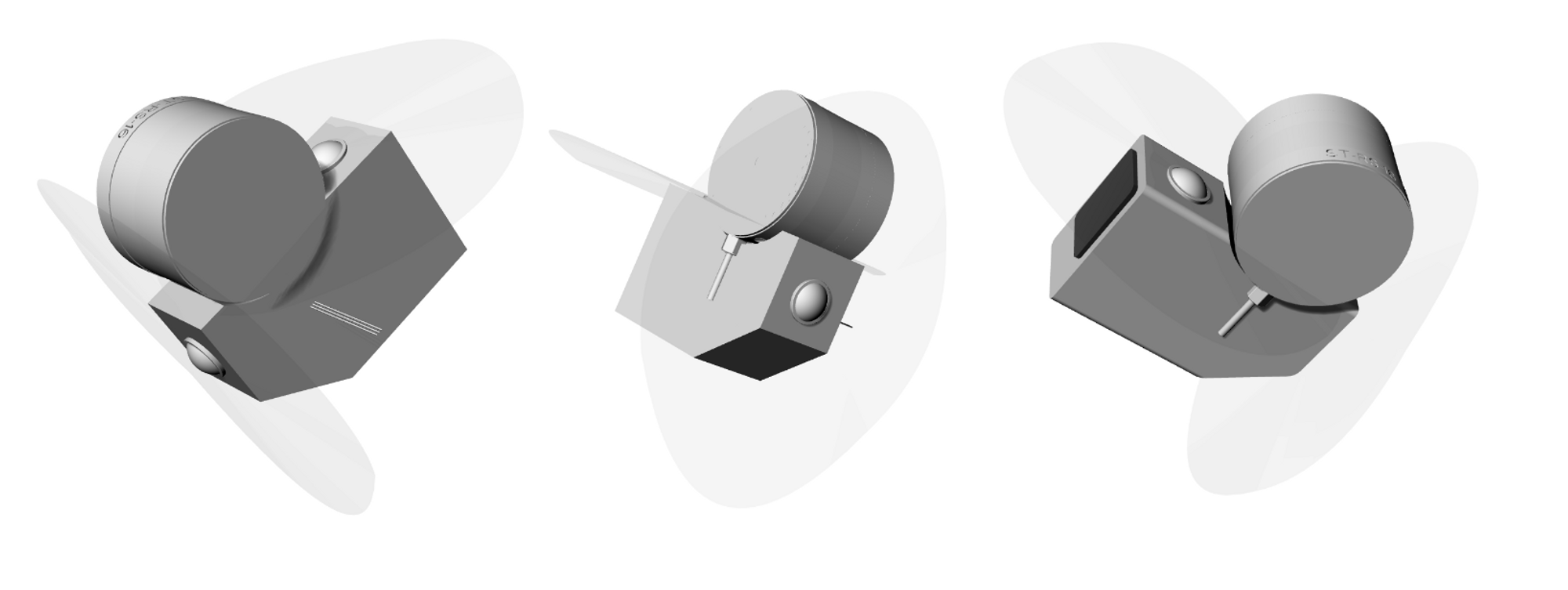

In addition to the simulation on the digital model, we also used 3D printed parts and aluminum profiles to build the frame, and simulated the counterweight with weights to test the real grip balance and feel.

The battery and camera are located at the bottom, balanced up and down.

The folding handle is located below the center of gravity of the fuselage and is balanced forward and aft.

The handle is in the middle and is balanced front and rear.

Can be held with both hands, more effort.

After communicating and discussing with the engineering team, we learned that the relative position of the camera and LiDAR was fixed, and the algorithm could better optimize the scan results, so we gave up the idea of folding the body.

The detachable design of the handle can be installed on a mobile car or drone in a lighter and smaller state, and it is also convenient to expand more accessories, such as RTK, panoramic camera, external high-definition monitor, etc. So finally we adopted the modular design of the handle split.

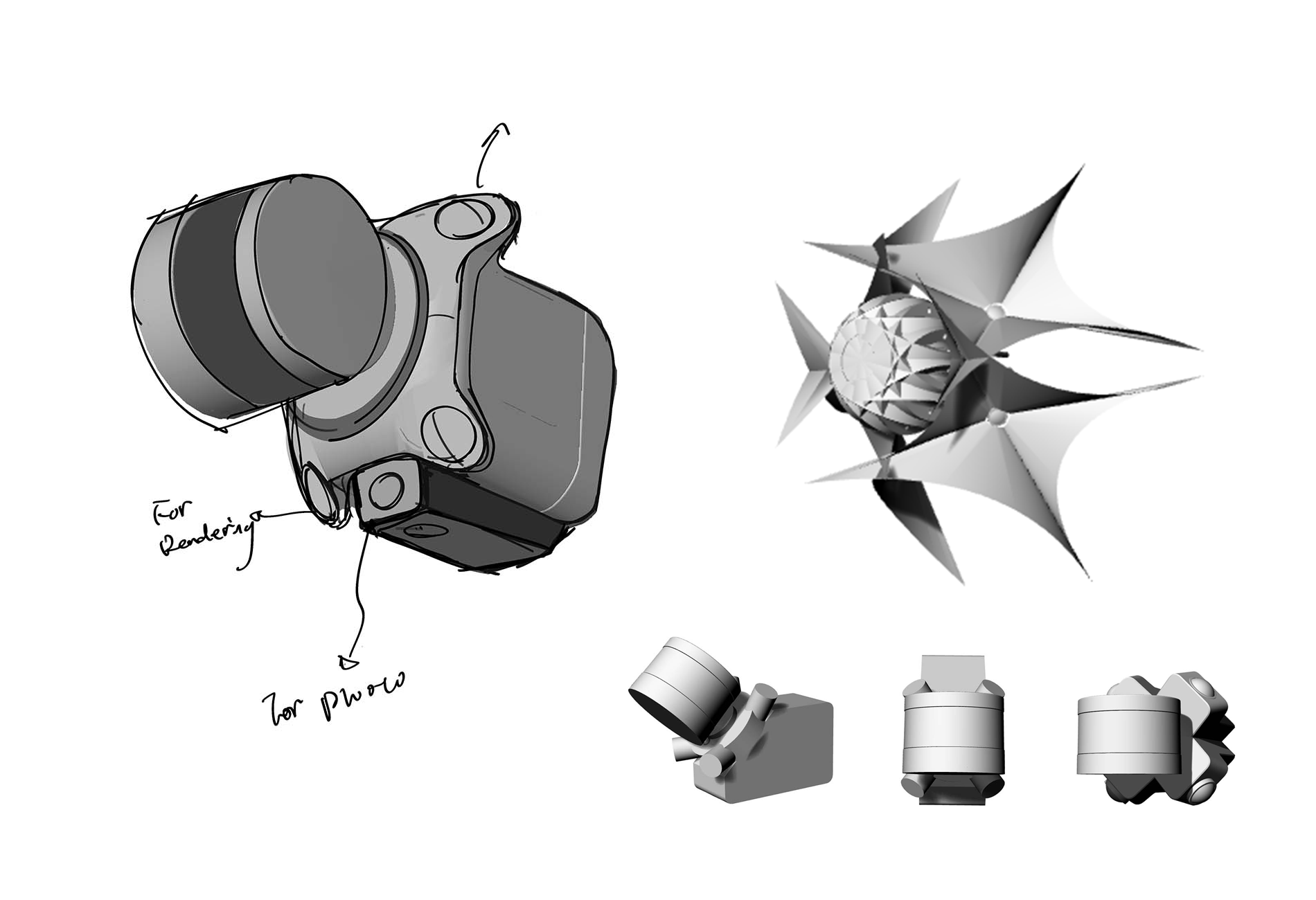

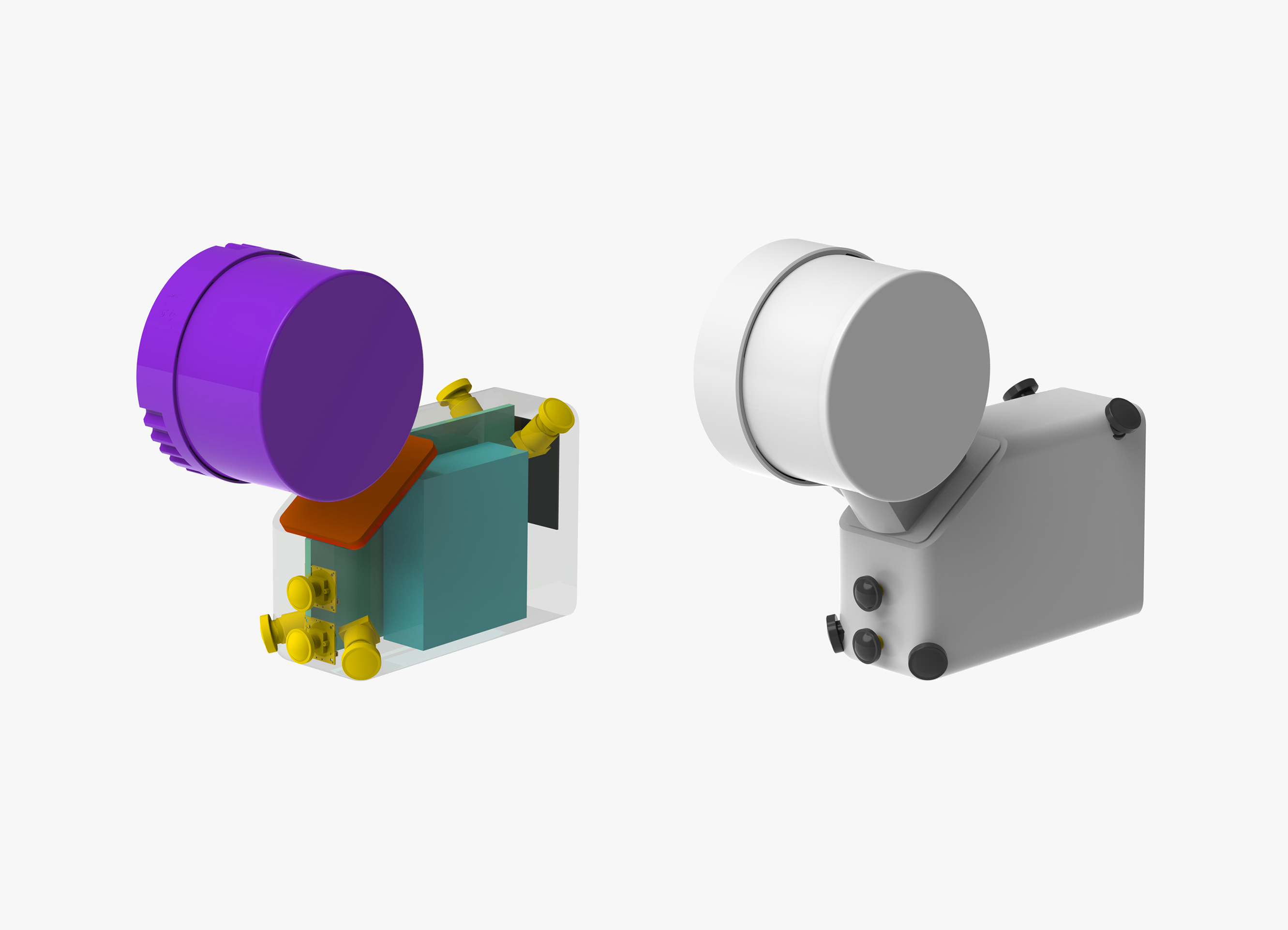

On a compact body, the FOV (visual range) of the camera is easily blocked by the front LiDAR. How to ensure that LiDAR and the FOV of the camera do not interfere with each other, the screen, battery, internal processor, SSD and other devices are reasonably distributed, and the architecture is compact, which becomes the design challenge in the next stage.

Therefore, we put forward the preliminary idea of arranging 4 cameras around LiDAR, which can achieve no blind area on the left and right, but can not avoid the blind area of LiDAR ball cone in front.

So we moved the front camera down to the bottom of the fuselage, and the upper camera moved back to the rear edge of the fuselage, keeping the camera as far away from LiDAR as possible to strive for a larger effective camera field of view. If the visual algorithm team evaluated and verified the architecture, it was found that LiDAR occlusion could be avoided and no blind area could be achieved at a field of view outside one meter.

The scanning function has been basically realized, and then we need to consider the ergonomic design problem.

In interviews with users, we learned that scanning often takes up to 4-5 hours, and that holding the device for a long time brings severe muscle fatigue. Due to performance requirements, devices such as cameras and LiDAR occupy a certain amount of weight. In addition to trying to reduce weight in the body, the design of the device's holding experience is also a crucial part.

We have observed that the user will use the left and right hands alternately when working to reduce one-handed muscle fatigue, so a symmetrical handle design is more appropriate. In order not to interfere with the FOV, the handle is arranged under the fuselage. During this period, the body volume, key position and handle feel were quickly verified by 3D printing model.

At the same time, the handle has the function of extending rod, which is convenient for users to scan higher objects, such as the top of the cabinet in the space. The bottom is equipped with a tripod to allow the device to be placed smoothly, and the initial position is calibrated before the scanning work starts.

During the scanning process, the tripod can be retracted as an additional handle and can be rotated at an angle to facilitate the user to hold it with both hands. Flexible grip accessories help users cope with a variety of complex environments.

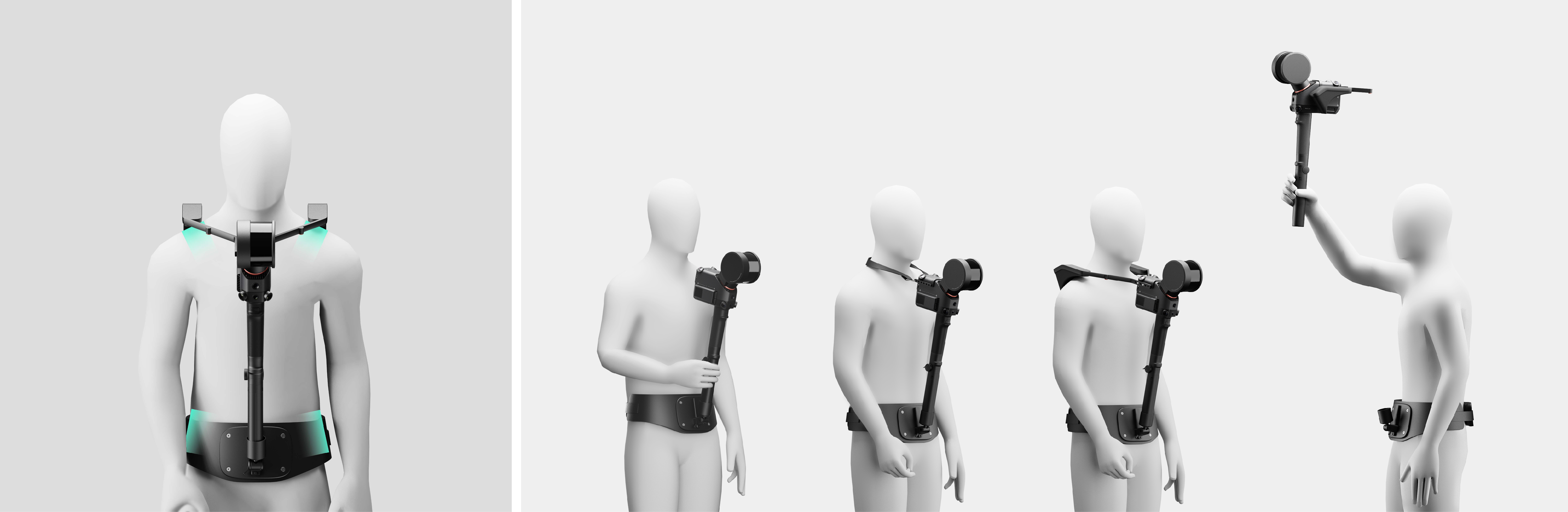

In addition to reasonable holding design, LEAPX team also designed shoulder bearing accessories to release the user's hands and let the waist and shoulders bear the weight of the equipment, which can greatly reduce holding fatigue. The support structure is made of aluminum alloy rigid material, the whole wearing process is clear, fast and stable, and the folding design is also convenient for users to carry.

The traditional soft strap needs to be adjusted repeatedly to ensure that it is close to the body and the wearing process is complicated. Poincaré shoulder accessories only use the three key points of shoulders and waist to achieve fixation equipment, and reasonably share the weight to the shoulders and hip bones.

1. Users can choose the wearing method according to the working duration: the belt is fixed and hand-held for short-term work; Soft shoulder straps are suitable for medium-term work. Folding shoulder frames are recommended for long-term work.

2. In order to adapt to the length of different people, the fixed point of the equipment and belt can be adjusted up and down by 10cm, covering 2.5-97.5% of the height of men.

3. The waist and shoulder accessories are separated independently. Users can quickly remove the equipment to scan the bottom of the table or the top of the cabinet, and it is also convenient to pass some special scenes (such as fire scene, narrow space, etc.).

Mounted in a car, robot dog or drone

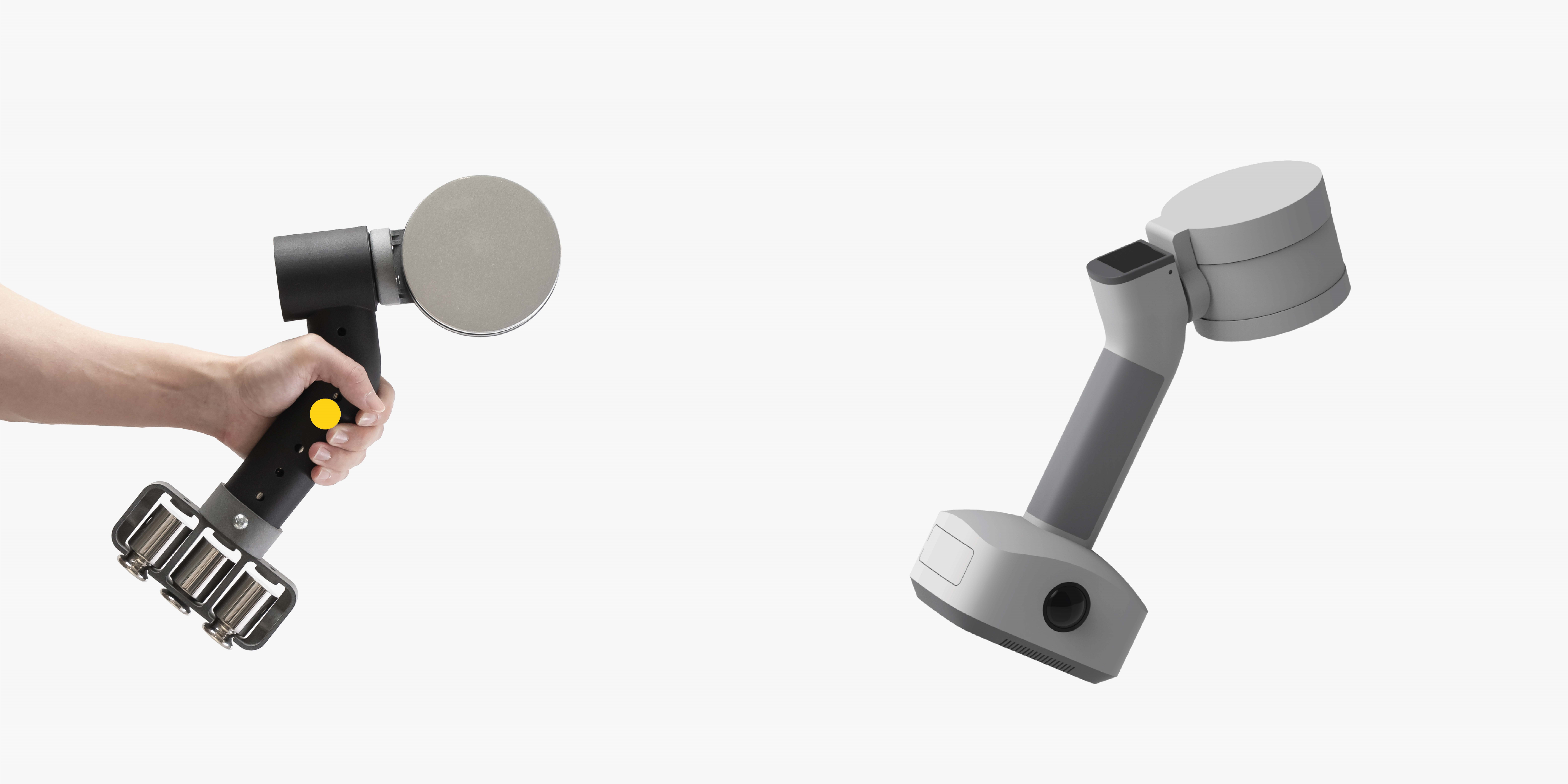

Aluminum CNC machining metal shell, light weight and strong

The bottom can be external tripod

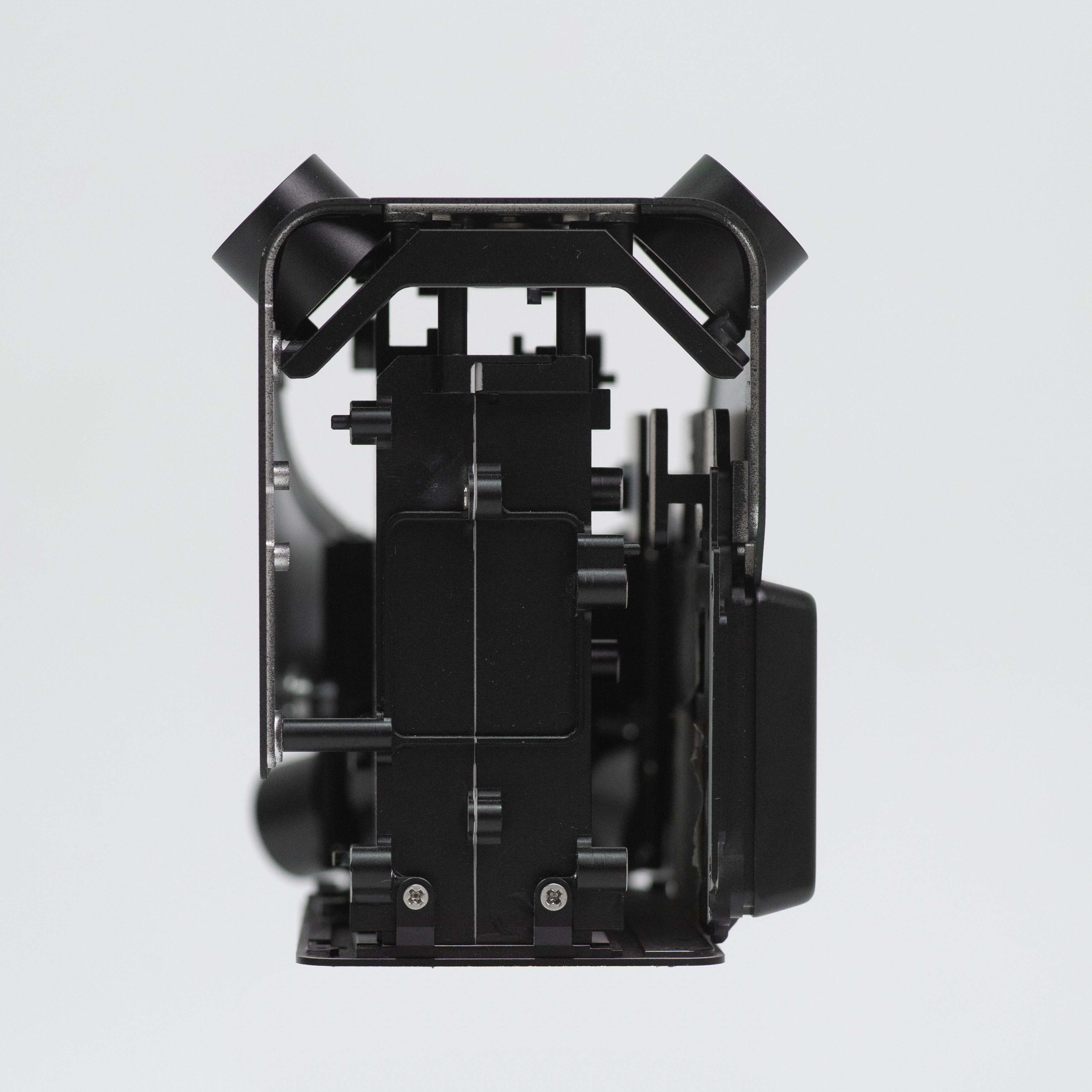

The battery is located in the middle of the fuselage, the PCB board is distributed around, the internal space is compact, the left and right weight is balanced, and the structure is stable.

Battery installed from the bottom

The handle is fixed to the bottom by quick release, just below the center of gravity of the fuselage.

Handle button can shoot scene details

Through rigorous calculation, we place the handle accurately under the center of gravity of the fuselage to achieve front and rear balance and improve grip comfort. The product can be erected on the desktop through the handle, which is the embodiment of balance.

Poincaré is equipped with 16-wire LiDAR, which rotates 360 degrees through an active motor to form an ultra-wide viewing angle of 360 ° x270 °.

Four 12MP ultra-wide-angle cameras are arranged around LiDAR, and work together to perfectly avoid the spherical cone blind area formed by LiDAR rotation in front, and color the space point cloud without occlusion.

The 12MP HD camera at the top of the front can quickly take local close-ups of key scenes, record scene details and location information, and facilitate users to view space details or asset management online.

The bottom is also equipped with a 60Hz SLAM camera. Auxiliary equipment can clearly identify space point clouds in dark light environment or in long and narrow corridors to help correct position and posture.

The heat sink surrounds the LiDAR drive motor to improve heat dissipation efficiency.

The internal heat is conducted to the outer wall heat sink, and then the internal dust-proof and waterproof of the device is realized through the active heat dissipation of the fan.

The buttons and display screen face the user for easy operation.

The top quick release interface can be installed RTK module to improve the positioning accuracy of the equipment.

On September 4, such as the "Poincaré" product launch. After the birth of Poincaré, it can gradually realize seamless integration with the products of Galois and other hardware products, such as professional acquisition products, to build a more comprehensive and flexible space acquisition solution.

The copyright of this work belongs to LEAPX Design. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Can the one worn on the body be designed with underpants

The combination of technology and humanities

How to buy?

Nice process !!!

Is our designer good at appearance and structure?

I don't know how much better this is than that broken oil pot funnel. This is fucking industrial design.

What is the reason why the heat sink was finally changed to convex wow

I forgot the information at the end of the article before, add:

About

LEAPX is a design studio founded by the original DJI Mavic Series Lead Designer/Product Manager. We believe in the value of design, in this impetuous environment to sink the heart to seriously design. Our goal is to combine technology and humanities in different industries to make innovative designs that can bring industry changes like Mavic.

Career

If you agree with our goal, welcome to join us and develop together with LEAPX. Currently recruiting positions:

Senior Industrial Designer/Director

Industrial Design Intern

Market Operation/Business Development

Please send your portfolio/resume to careers@leapx.design

Opportunity

We are also actively seeking to design the pursuit of the company for project cooperation, if you have a product needs the ultimate design, we are eagerly waiting, please write to contact@leapx.design

This is what design should look like.

What application scenario is this?

3D art to see such a design silently shed tears

This kind is really beautiful

The high-end design is so wonderful

A good product display is telling a beautiful story.