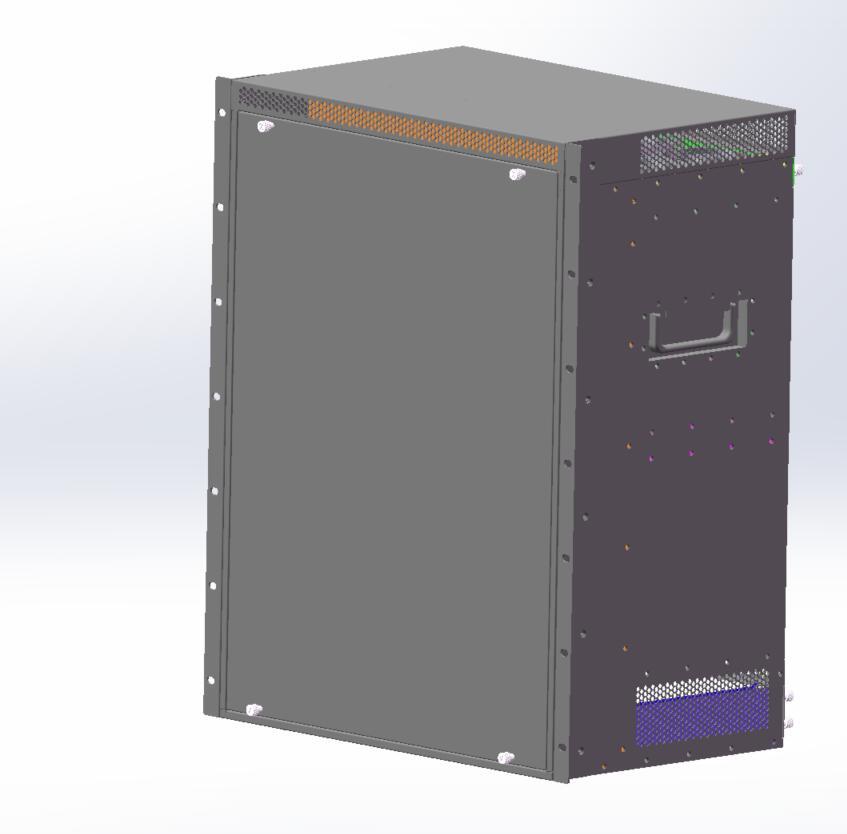

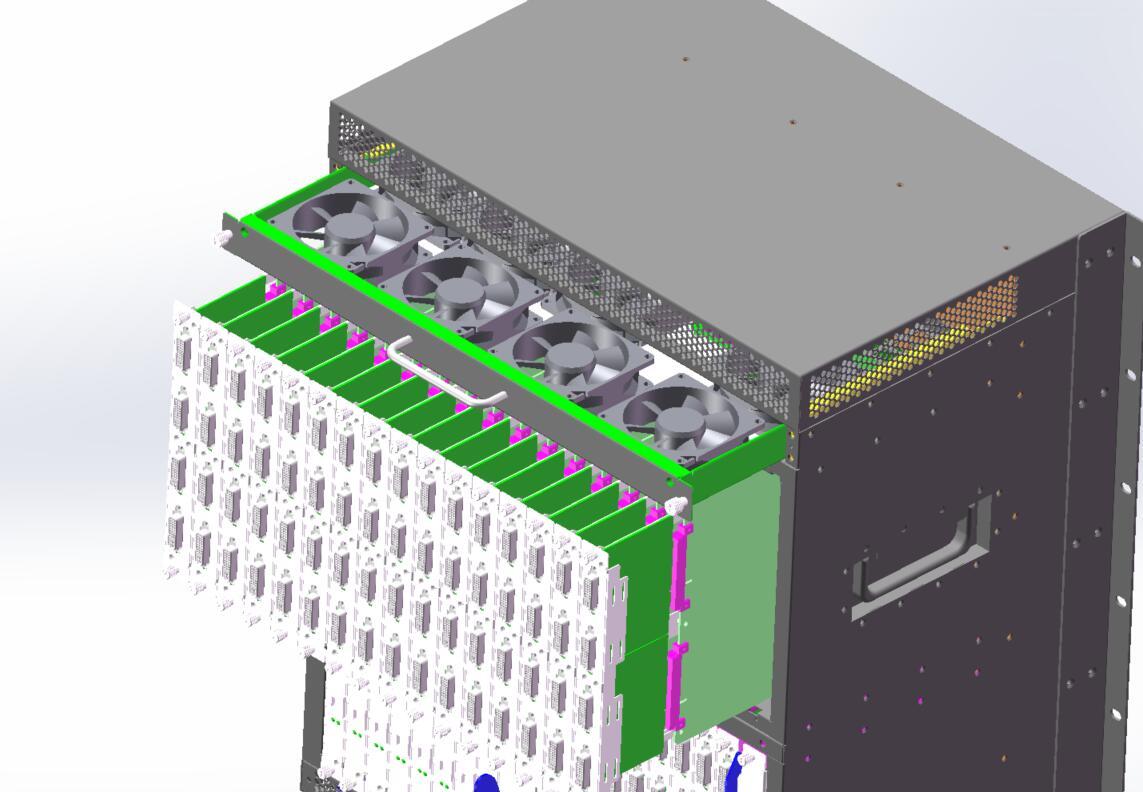

This is a standard chassis (plug-in box) designed a long time ago, with a total of 13U. It is used as a splicing processing platform in the video processor industry. How to use it is not described here;

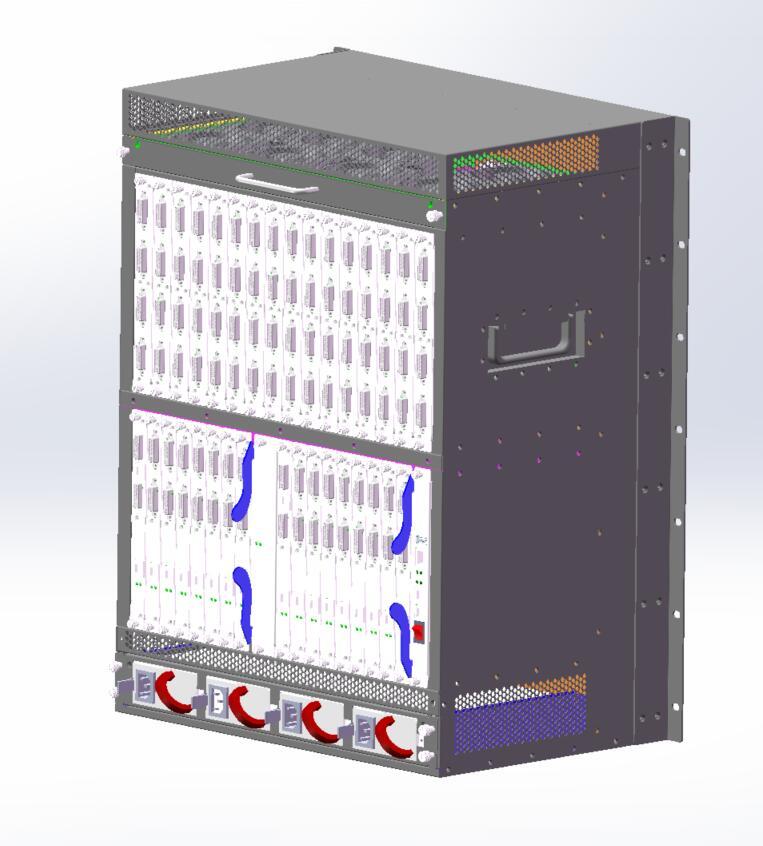

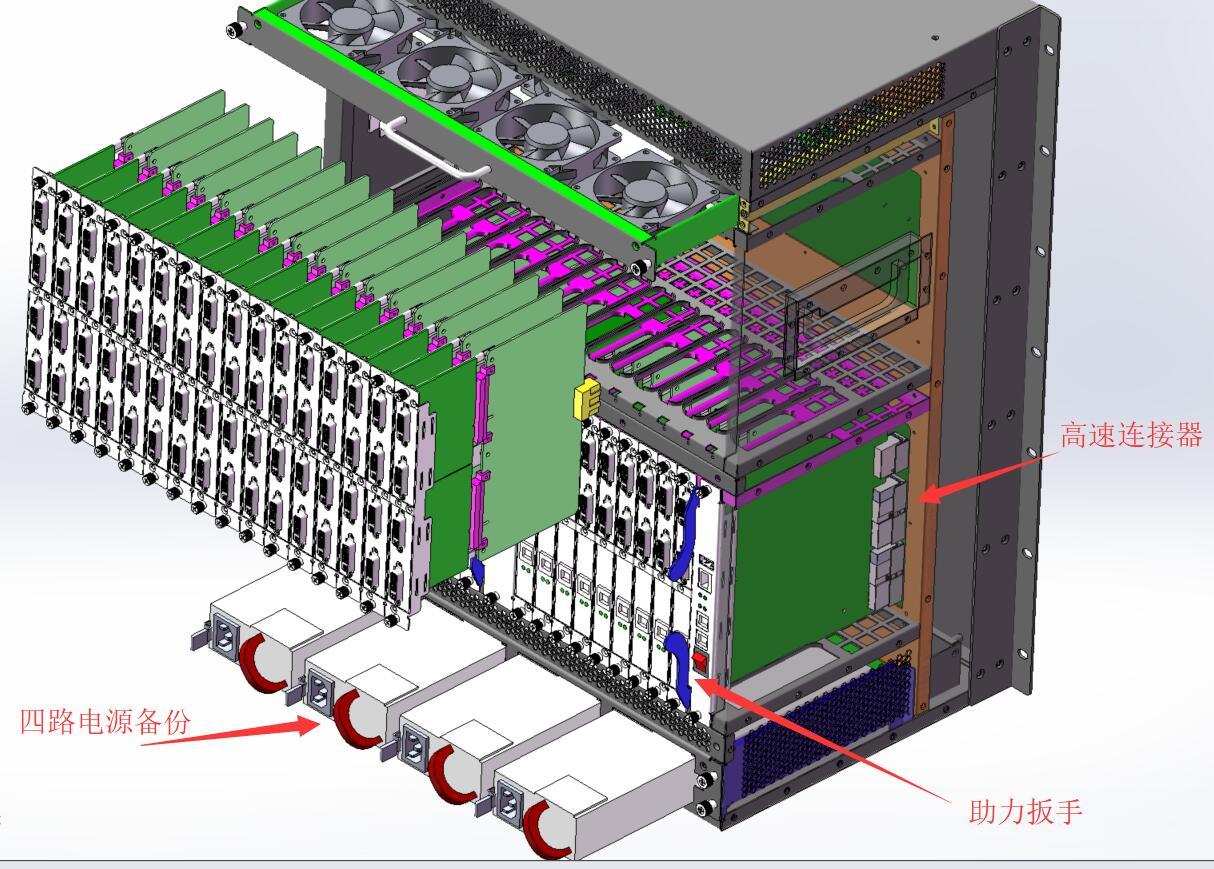

The chassis looks very large, the structure is also very complicated, and the coordination requirements are relatively high, because there are many boards on the top, and different boards will be replaced according to different usage requirements;

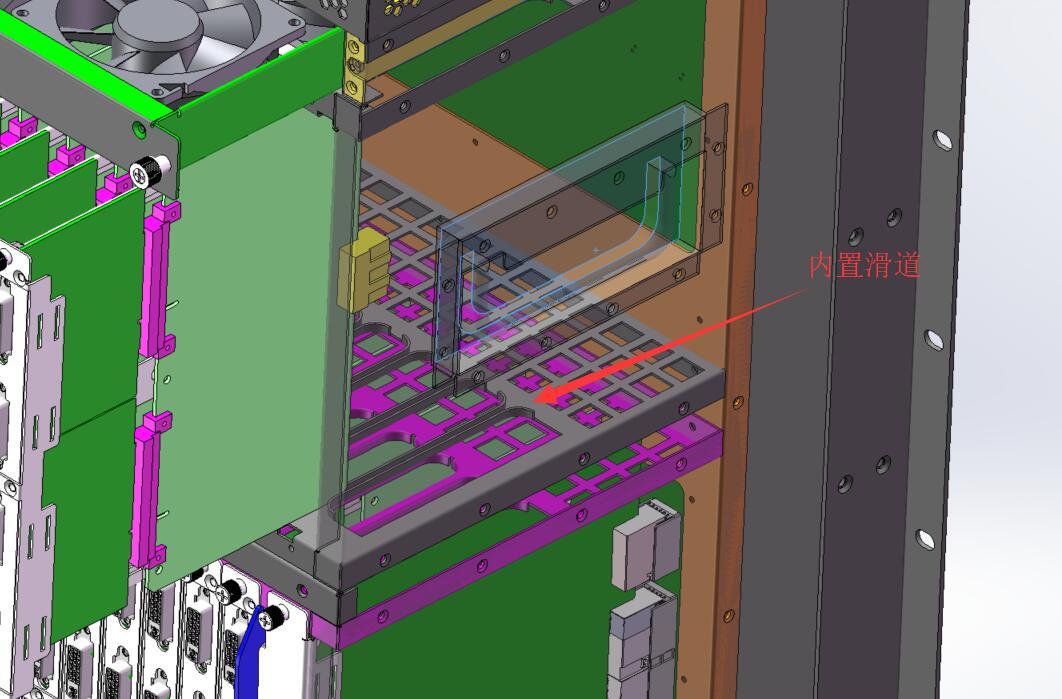

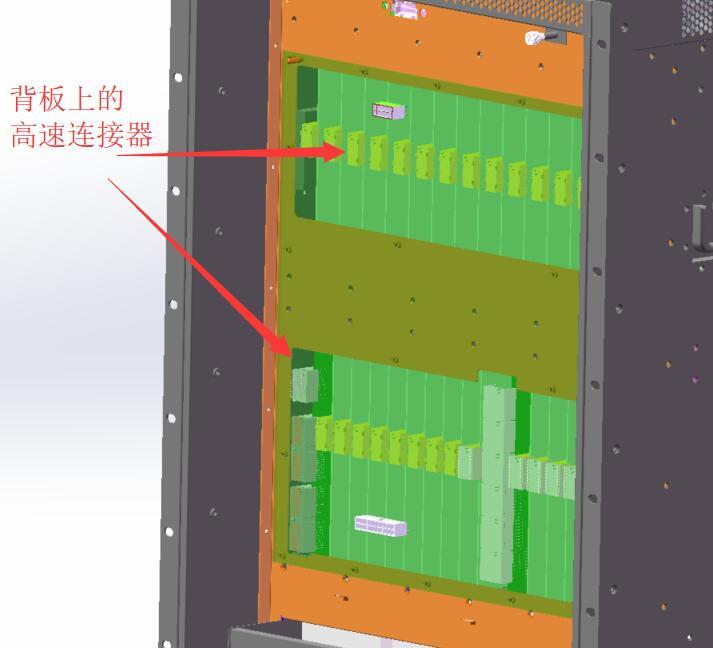

Each board is plugged into the back plate of the chassis by drawer, which requires their matching accuracy, because if the matching accuracy is too low, the connectors may not be accurately docked when the board is inserted, resulting in damage;

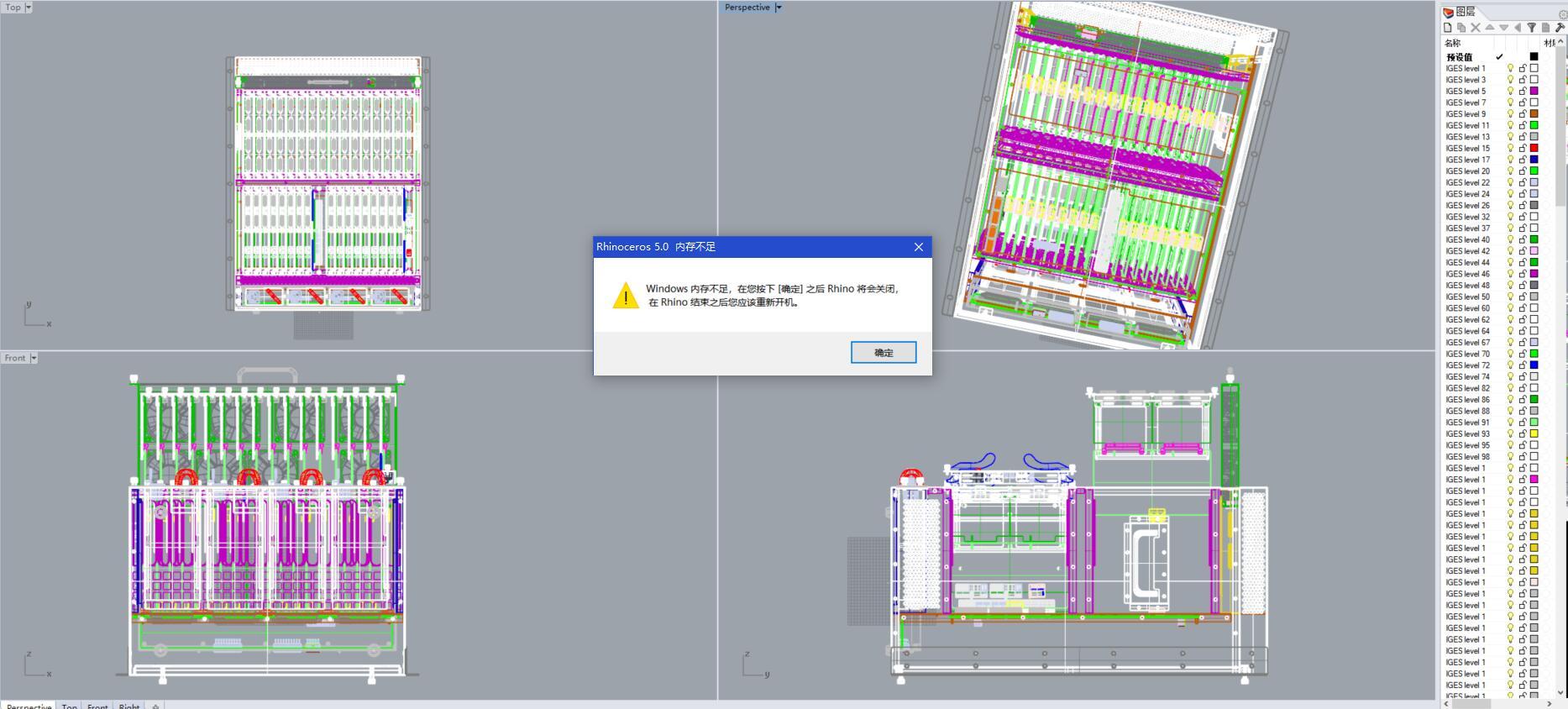

However, the file is really big. I wanted to render the picture again, but the computer was not good enough. I tried several times in a row and was stuck. I could only take some screenshots. Friends can see it first!

The following content is copyrighted and infringement must be investigated! Please contact the author if necessary!

The file is really large. After importing rhinoceros, it is stuck directly, not to mention layering and rendering. The main reason is that there are too many parts, various card slots, tracks and connectors. Of course, maybe my computer should be upgraded, or the software is not set correctly.

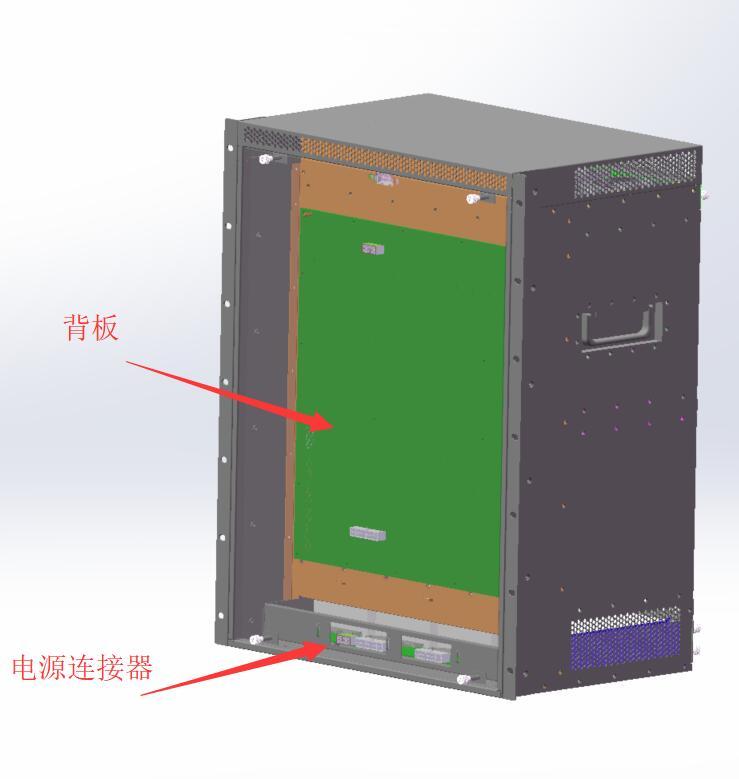

This is the front panel of the chassis. It looks simple and unpretentious. After all, it is pure sheet metal processing now, and it can't produce too complicated shapes. However, later we designed a plastic panel and injected some domineering elements. We will see if we can sort it out and communicate with you later.

The rear panel has many interfaces and is densely packed with interfaces. Some special boards are very considerate and designed with a power-assisted wrench. After all, the high-speed connector is very tight after being plugged in. With the power-assisted wrench, it can be very labor-saving when plugging and unplugging the board.

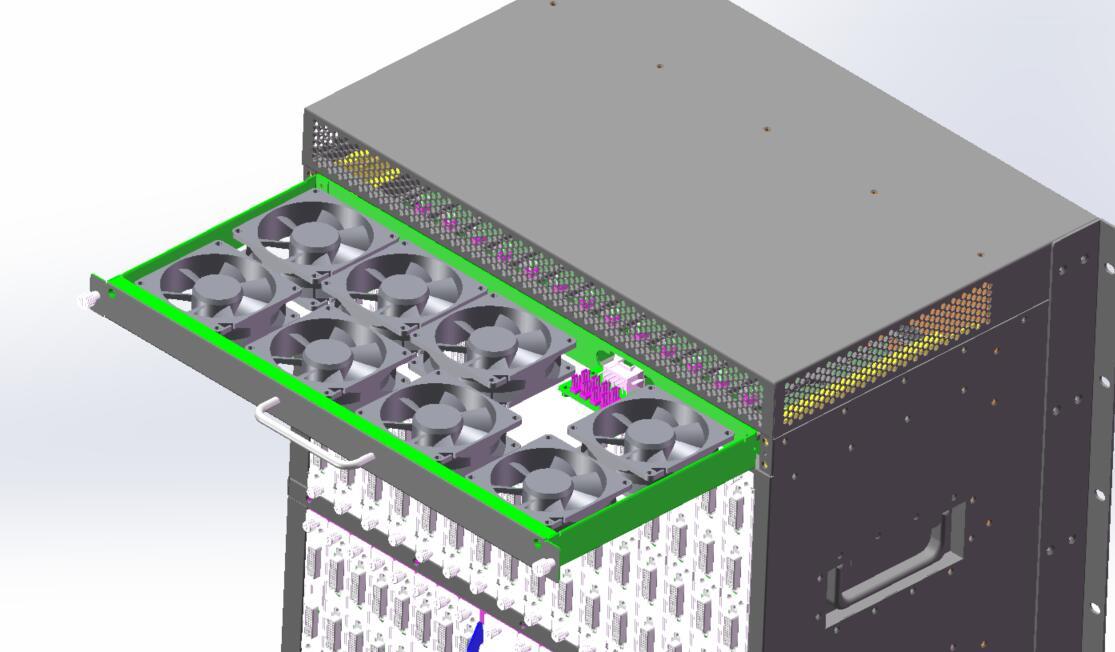

The fan is inserted into the box. It is said that the heat of the whole machine is still relatively large, so several more fans have been added.

All the following boards can be replaced and spliced at will according to the use requirements, because this is only modeling, so I draw all DVI interfaces. If other interfaces are used, the opening structure of the baffle will also change accordingly.

The sliding track inside, sheet metal stamping processing.

The standard power supply selected is stable and reliable.

Connector behind board

The copyright of this work belongs to 外观&结构设计 |实体公司可开票. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Really detailed