We hope to explore the design focus of an outdoor mobile phone case from the essence of protection

Is simple solidity really protective? Imagine a person standing in an unbreakable elevator. The elevator falls from the 20th floor. The answer is no, because the nature of protection is not strong, but disperses the pressure, slowing down the impact on the protected object.

Only better cushioning can withstand a stronger impact test.

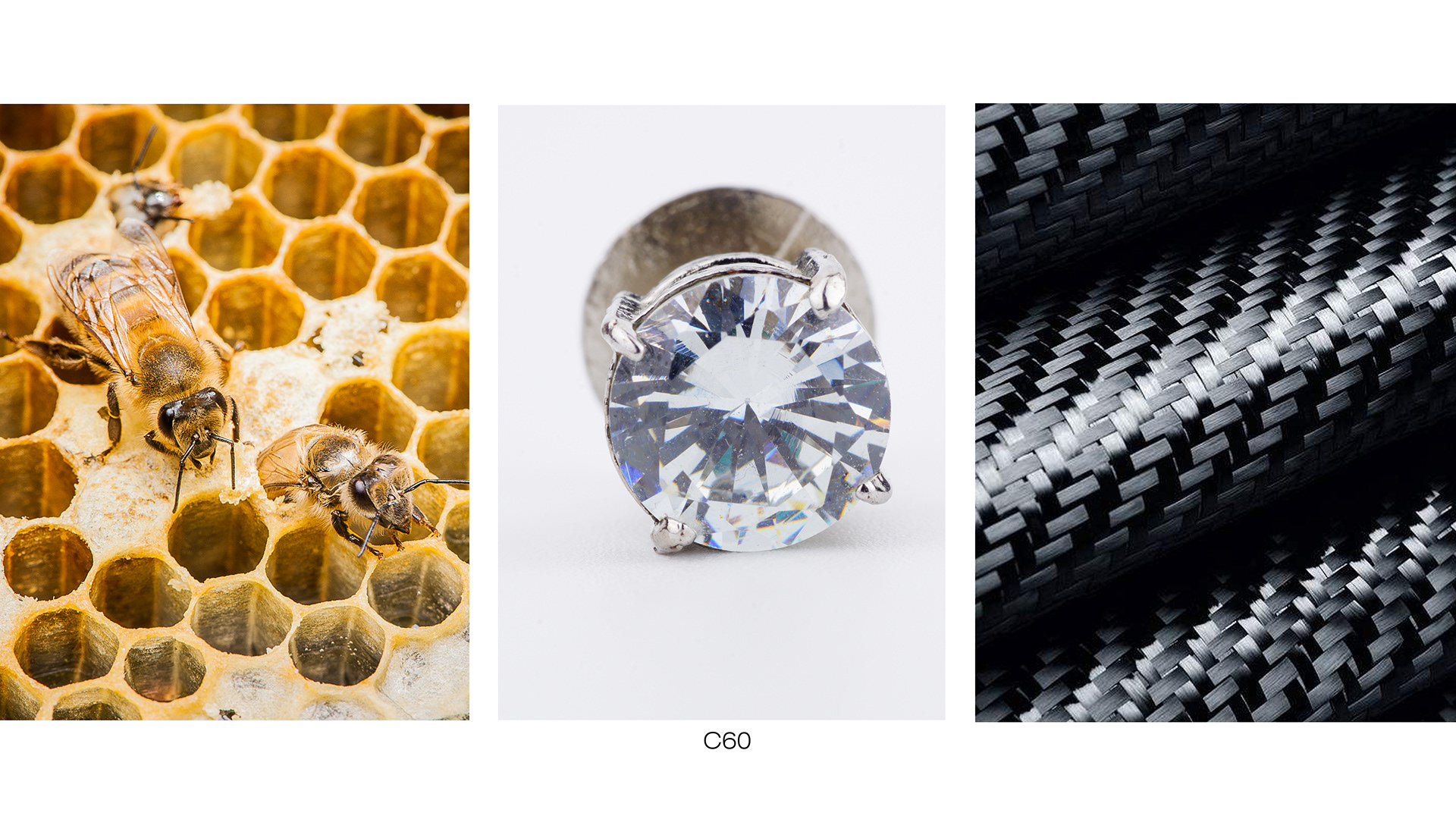

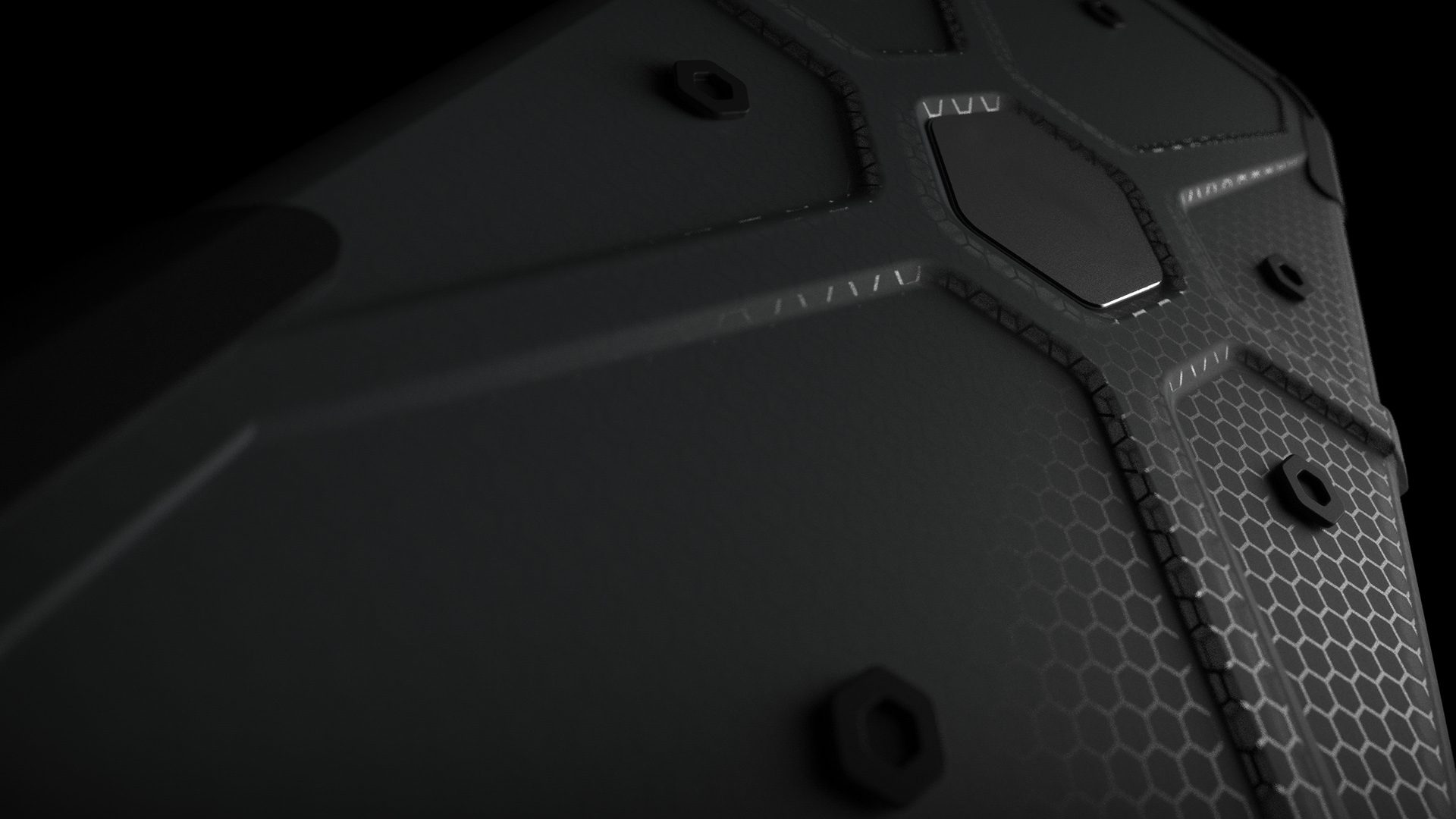

The C60 molecular model, which constructs the hardest substance in the world, is precisely because its single-sided molecular model is equilateral hexagon, which makes them have the highest strength after joining.It is worth mentioning that the reason why honeycomb is formed with equilateral hexagonal structure is that the equilateral hexagonal connection mode is the one that saves the most materials in nature and has the highest strength at the same time.

The C60 molecular model has the highest hardness precisely because it is joined in the same way.

The strength of an equilateral hexagon is not the result of a single equilateral hexagon, but the way it is connected.

Therefore, the equilateral hexagonal li-nkage elements frequently appear in many works of future themes.

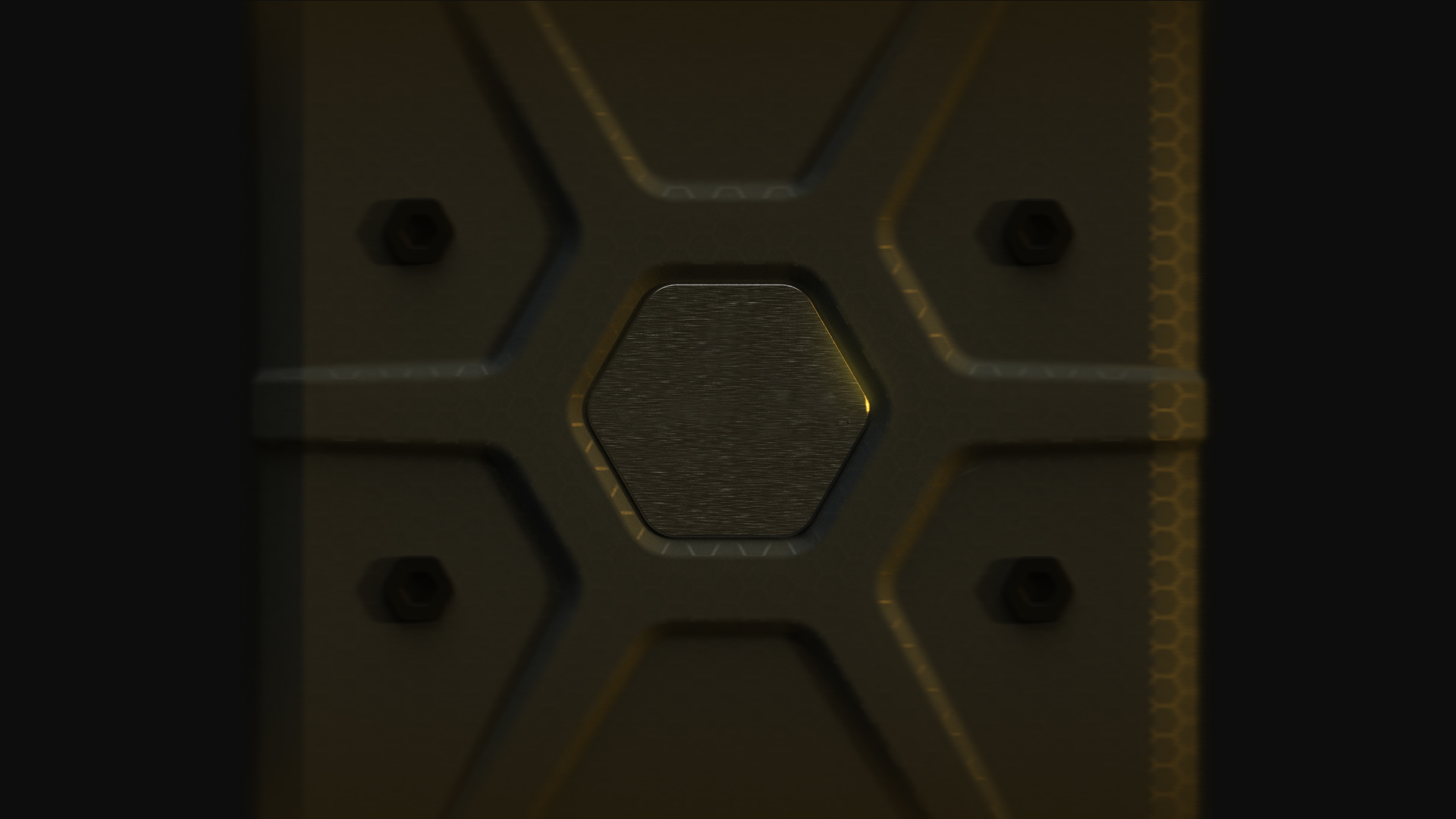

So we found another way to make the ba-se material of our product have high strength, which is to use the equilateral hexagon mesh connection, so that the pressure can be equally spread to every corner.

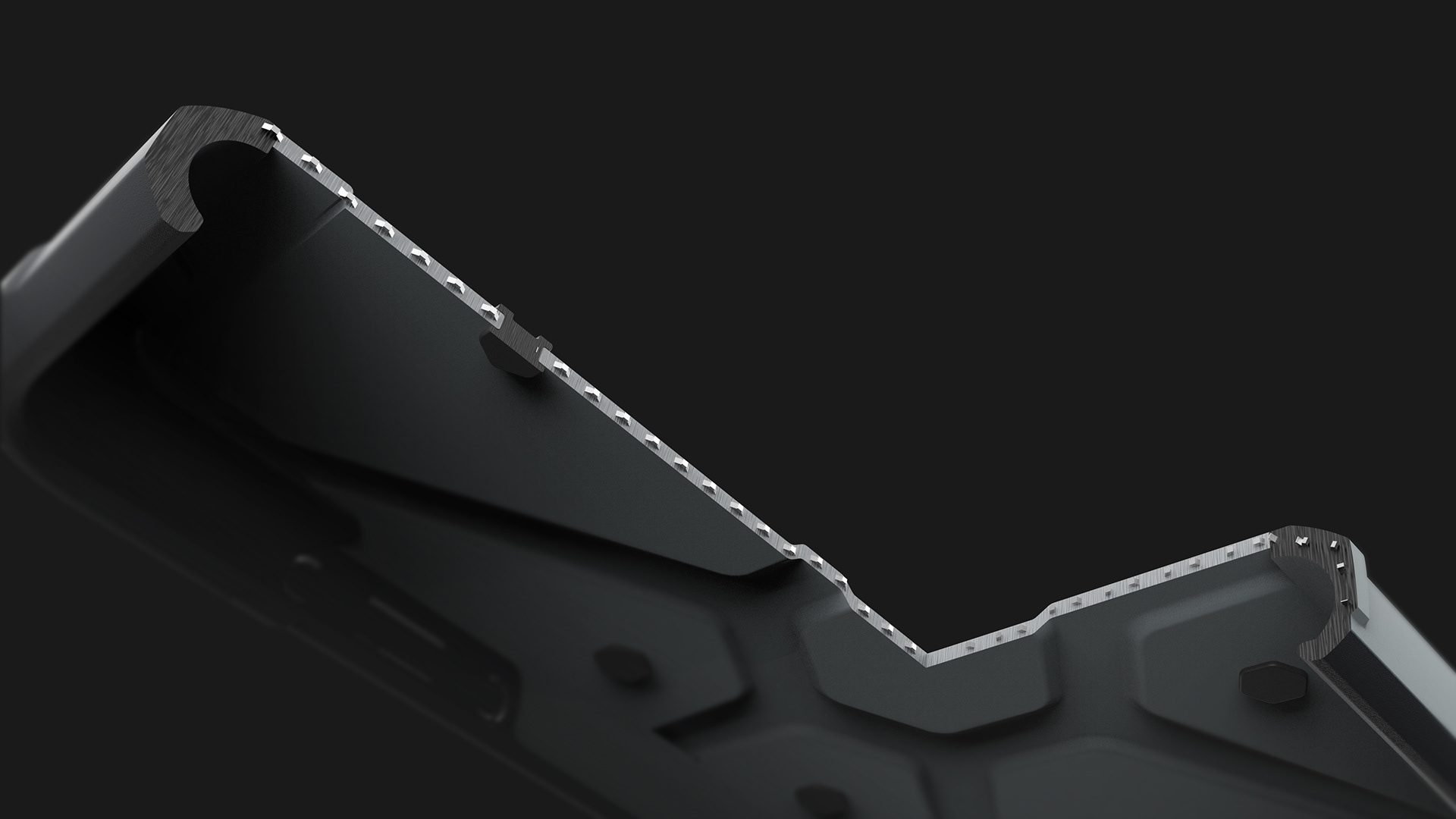

Of course, larger reinforcement bars are still an essential and important design to help us play the role of the last line of defense in dealing with level 3 shocks.

The second line of defense is the equilateral hexagon mesh connection that we injected into the ba-se material in advance. They are looming in the translucent ba-se material.

With our first level of cushioning silica gel, we press against the back of the phone in the most gentle way and disperse the pressure balance to every corner of the product with an increasing three-level cushioning design. This diagram clearly demonstrates the distribution of me-tal mesh in translucent substrates with equilateral hexagonal connections.

Equilateral hexagonal connections evenly distribute pressure in different directions to each corner

The equilateral hexagonal me-tal mesh exists in every corner of the main shell by injection molding in the inner part of the substrate, which is not just a simple decoration.

Equilateral hexagonal me-tal mesh, coupled with larger reinforcement bars, can evenly distribute the hedging pressure in each direction under the combined action of both hexagonal shapes, which is rare in other forms of dispersion patterns.

me-tal mesh in the semi - transparent substrate is looming, presenting an indestructible sense of the future.

The partial position of the front side we made a little bump to deal with the large area of friction of the desktop on the product.

Different colors of me-tal mesh, and different colors of translucent substrate, can be combined to create more possibilities.

The copyright of this work belongs to CHENYONGDESIGN. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Big Brother