This desk lamp was made a year ago. At that time, the internal entrepreneurial team just set up and didn't think about what to do. It took half a year to investigate and investigate. It still returned to the application of light that is somewhat related to the main business. An intelligent eye protection homework lamp that can help parents understand their children's learning time and efficiency.

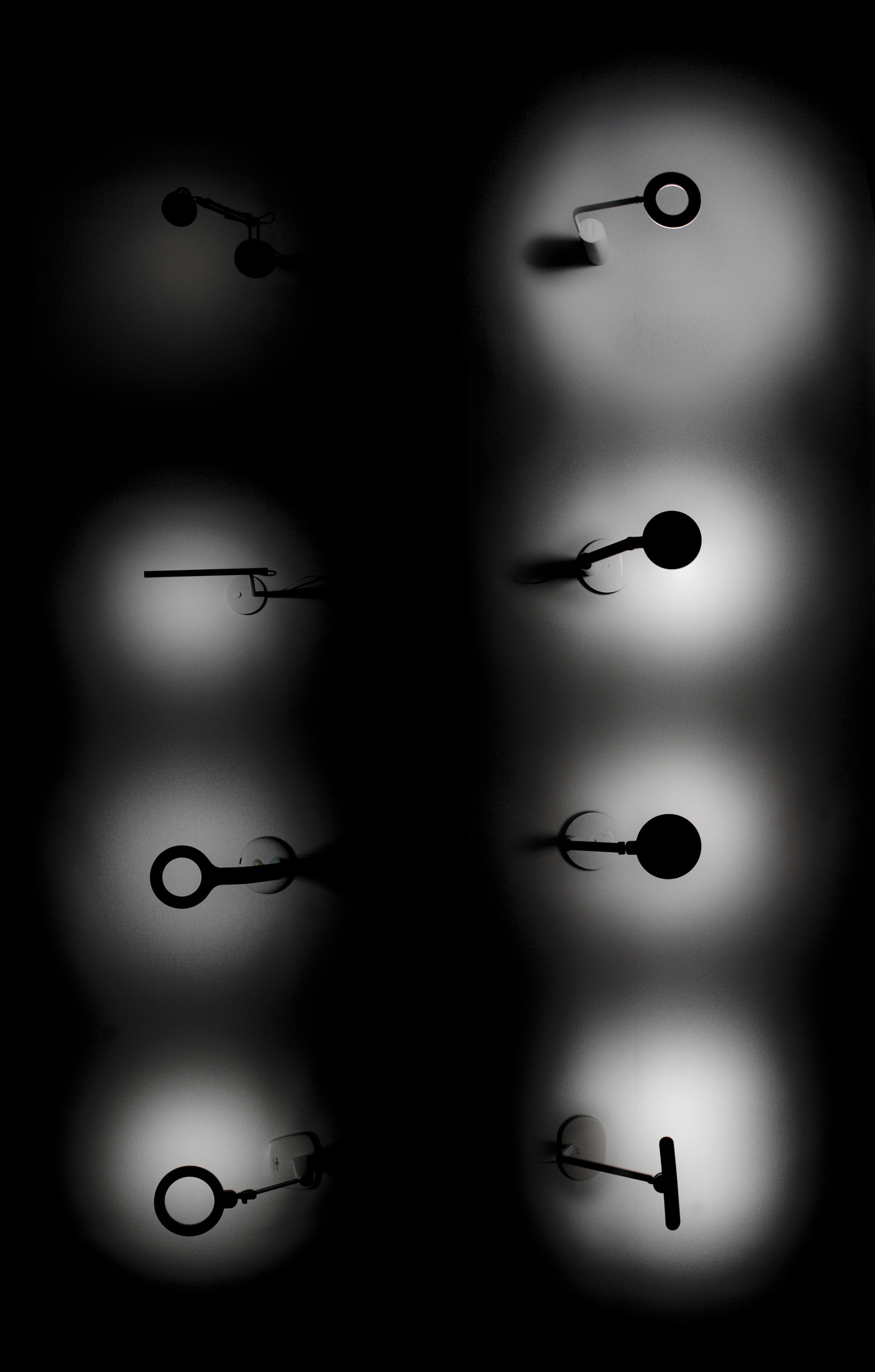

The shape is very out of line, with only one visible shaft, and the base becomes cylindrical, using the same electric lift as the elevator.

The idea was killed at the beginning, why add an electric vertical lift to the desk lamp?

This is obviously a pseudo demand! The hands are all in front of the lamp. Adjust the lamp pole to get rid of things that do not require additional costs. Why do you need to spend tens of dollars to make it electric?

The lamp pole has to be bent and CNC with the structure. The cost of realizing this electric lifting is enough to buy a millet desk lamp!

The reason why the scheme was finally adopted is that when the vertical lifting allows children to adjust the height, the center of the light source does not shift (see the bottom moving picture), which is beneficial to users. As for why electric power is used, this is the basis for upgrading the next generation of products.

In order to solve the standing problem of the cylindrical body, it took a lot of effort. The pressed cast iron is almost one kilogram. In addition, a micro-suction cup has been added. On a relatively smooth surface, hanging upside down is not a problem, but it is not recommended that you use it this way, in case it is too dangerous to smash it down.

The whole product adopts matt white straight out of the mold, and the mold cost is nearly one million. I think it is a pity that the shaft of the lamp cap is originally designed to be very small. It is not necessary to adjust the pitch by friction. As a result, the mold is opened and bowed under the two shakes. There is no way to redesign it. The joint is changed and the shaft is increased, so there is no problem in hand feeling.

Taking the products to participate in the Guangya Exhibition attracted the bosses of the lamp bosses. After the praise, they all shook their heads. It was too expensive to sell...

The current situation of domestic original design is like this. You spend time, manpower and funds on research and development, and the cost of the products you make remains high. The latecomers take your machine, three times, five times and two times, to make much cheaper products, and to be laughed at for a lot of stupid money.

The original enterprise has suffered. Come on, originators!

The copyright of this work belongs to inway. No use is allowed without explicit permission from owner.

New user?Create an account

Log In Reset your password.

Account existed?Log In

Read and agree to the User Agreement Terms of Use.

Please enter your email to reset your password

Very good, how much is the cost of this lamp?

The high cost is really difficult to do. I have done a plan similar to yours before, but there is no vertical lifting point. The customer killed because he had to add more counterweights to stabilize the cost of the base and abrasive tools.

Super great

I think the bottom surface should also be photographed.

Legend has it that when you are the best, the latecomers cannot plagiarize more than you.

That's great.

The layout of the penultimate picture amazed me ~ ~

Can you teach me how to play?

It's really great!

It's really a little expensive

I believe there is still a market for such a good design. Come on

Original is not easy, support